Feedback device for detecting descending position of workpiecepretargeting tray

A feedback device and pre-positioning technology, applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as improper clamping of workpieces, broken tools flying out, and damage to fixtures, and achieve safe and reliable clamping process. The effect of making installation convenient and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

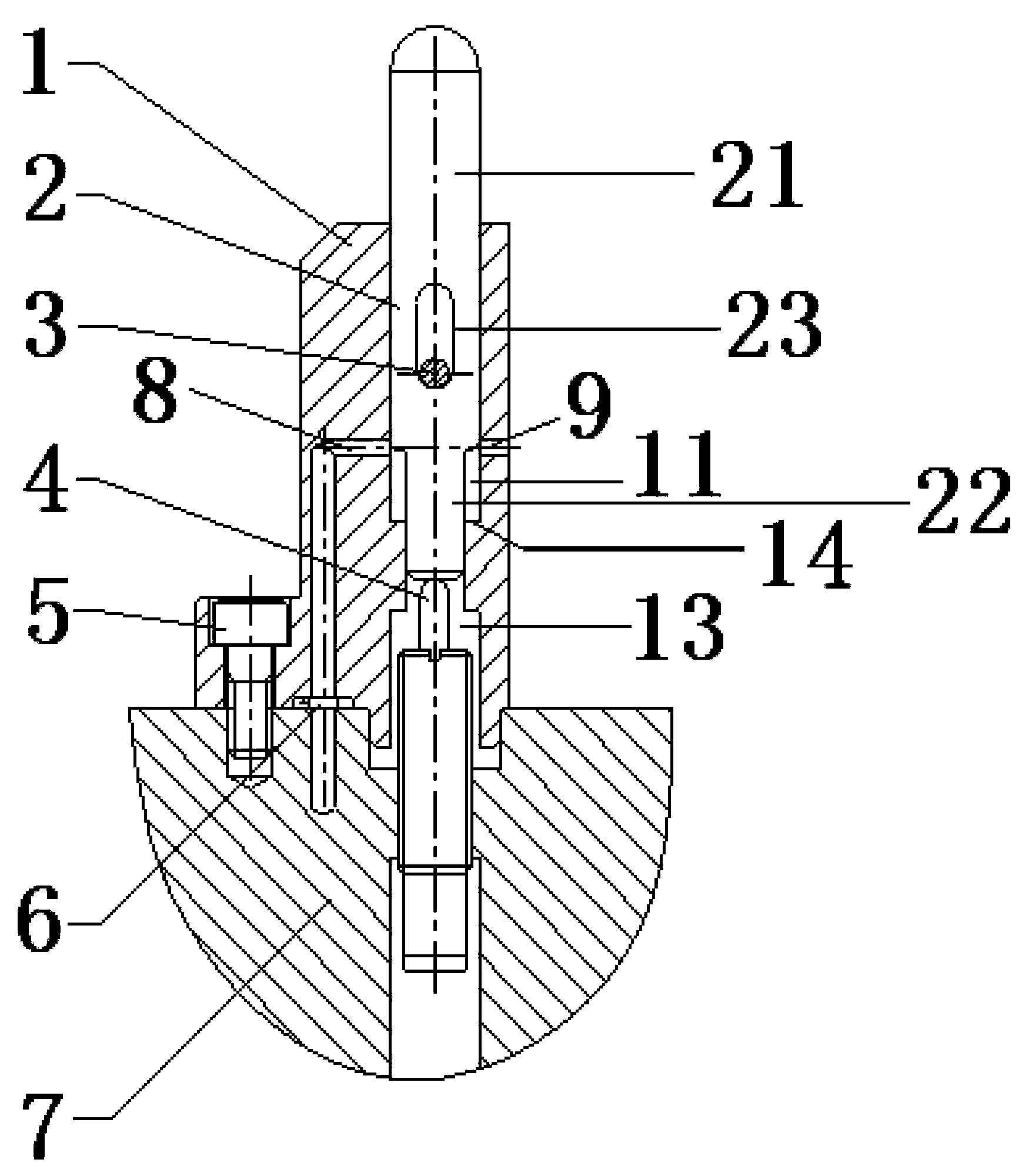

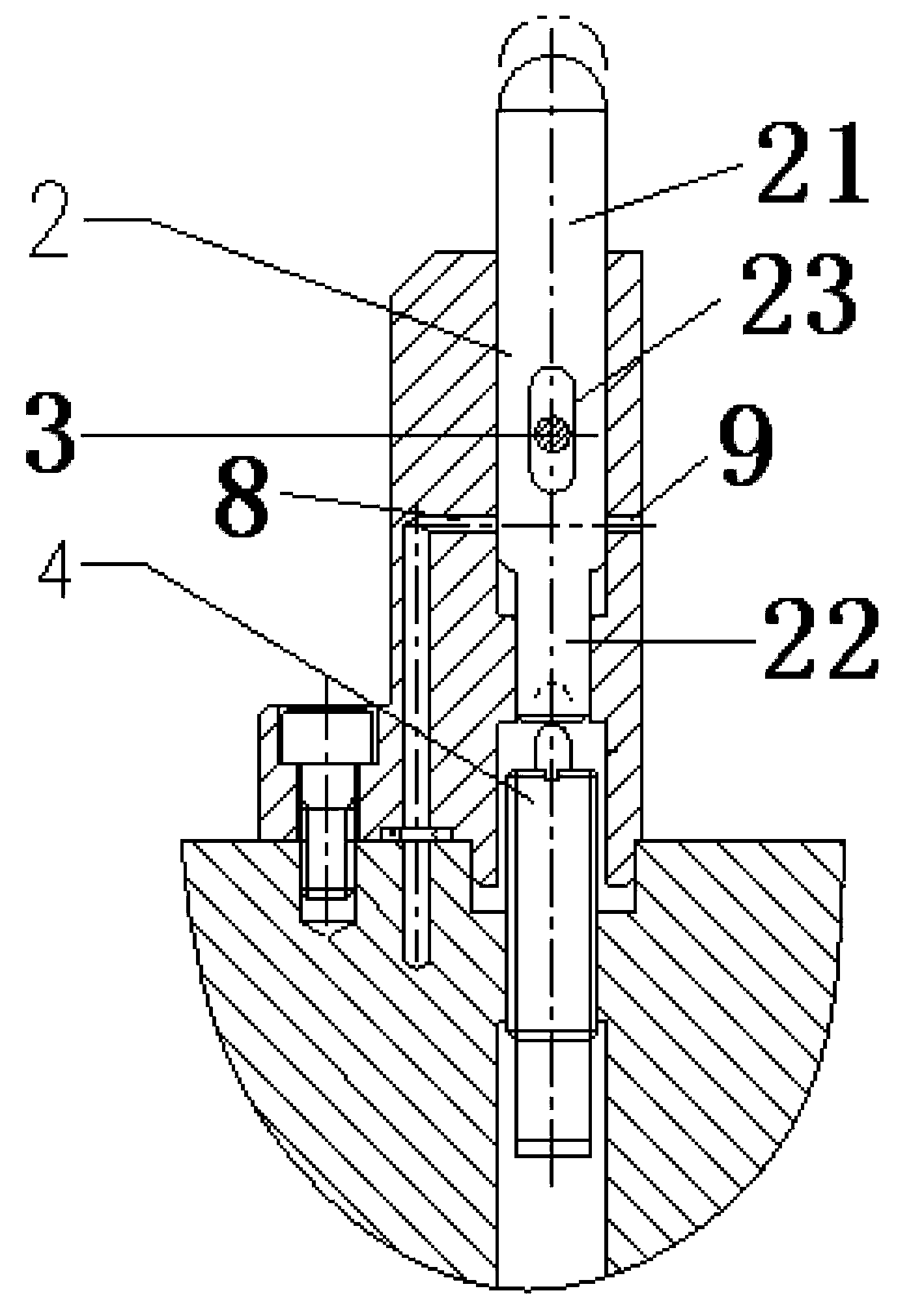

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0023] Such as Figure 1 to Figure 7 As shown, the feedback device 200 for detecting the lowered position of the workpiece pre-positioning tray 300 includes a main body 1 , an action rod 2 , a straight pin 3 , a spring plunger 4 and a gas sensor 101 . in:

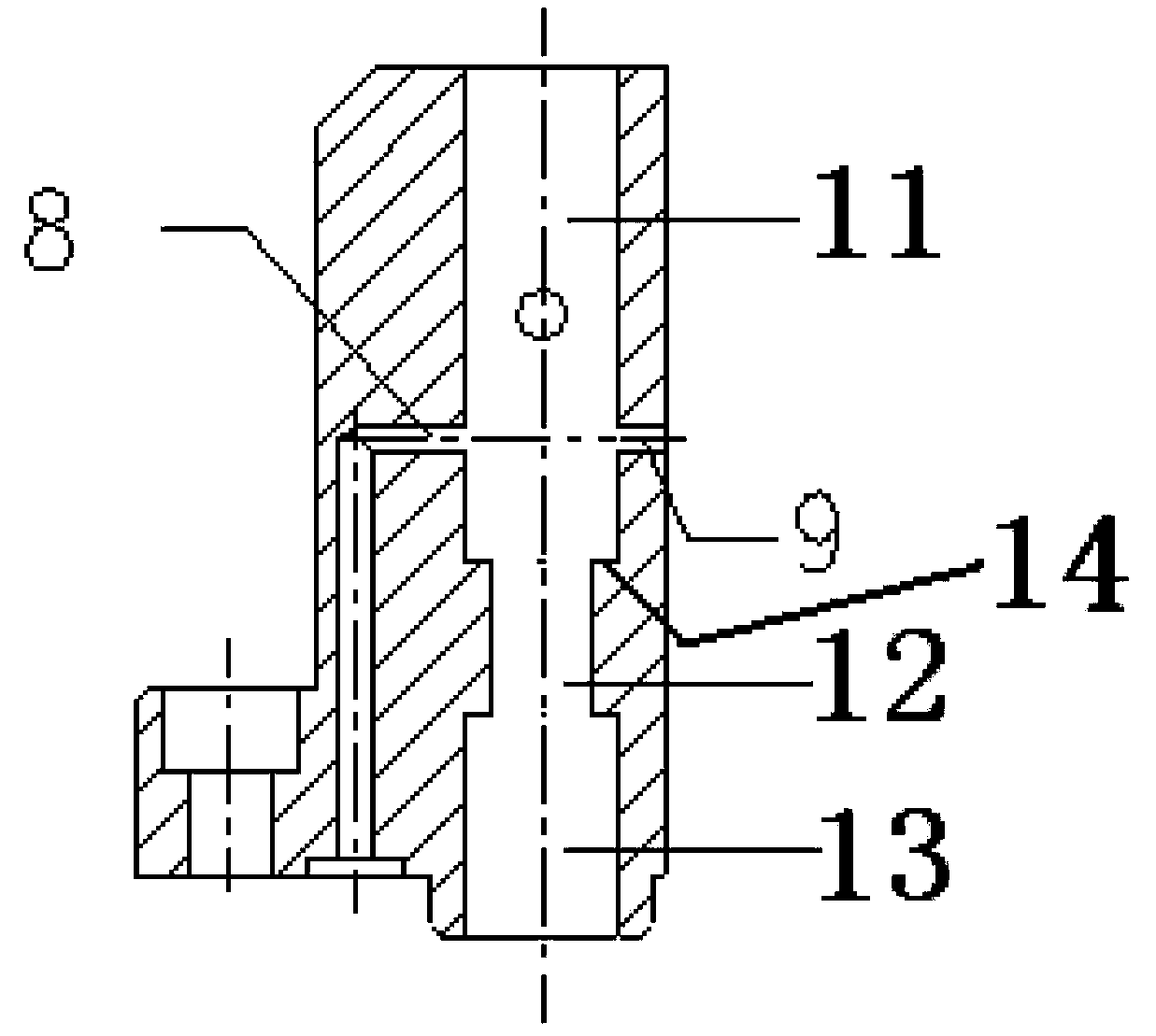

[0024] refer to image 3 The main body 1 is fixed on a clamping body 7 through bolts 5, and the main body 1 includes a longitudinal through hole and a transverse air channel connected to each other, preferably vertically staggered, and the transverse air channel is connected by the longitudinal through hole. It is divided into a first airway 8 on the left side and a second airway 9 on the right side. Wherein, the left end of the first airway 8 is connected with the detection airway in the clamp body 7 (a detection airway is arranged inside the clamp body 7, and the detection airway is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com