Industrial abrasive belt production method based on flax fabrics

A technology of linen and abrasive cloth, which is applied in the field of producing industrial abrasive cloth based on linen, can solve the problem that the base material of the abrasive belt does not have a grinding function, and achieve the effects of enhancing mechanical properties, improving grinding performance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

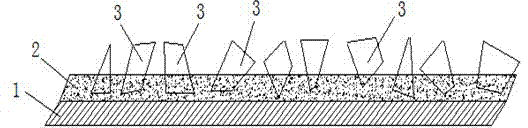

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0019] Such as figure 1 Shown is a method for producing industrial emery cloth based on linen. Taking sisal as an example, the present invention uses sisal with low cost. The sisal is impregnated with glue and scraped, and abrasives or Its short-cut fiber makes it have a grinding function, so it can be used directly, or further coated with primer on the surface of the sisal cloth, and the abrasive material is formed by planting sand on the surface of the coated sisal cloth. layer, which greatly improves its tear resistance. The production process is: first dip the sisal cloth in glue, scrape the slurry, then apply primer on the surface of the sisal cloth, then plant sand to form an abrasive layer, and continue to coat the abrasive layer. Glue, of course, it is also possible to directly impregnate or scrape the base material with abrasive or chopped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com