Device, method and system for detecting height of forklift pallet fork

A fork and height technology, which is applied in the field of forklift technology and power electronics detection, can solve the problems of easy damage and low precision of the rotation sensor, and achieve the effect of improving measurement accuracy, high precision, and reducing length and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

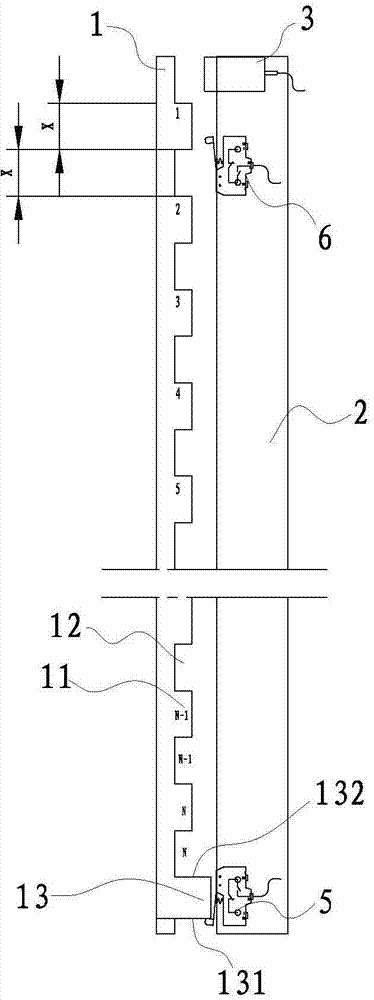

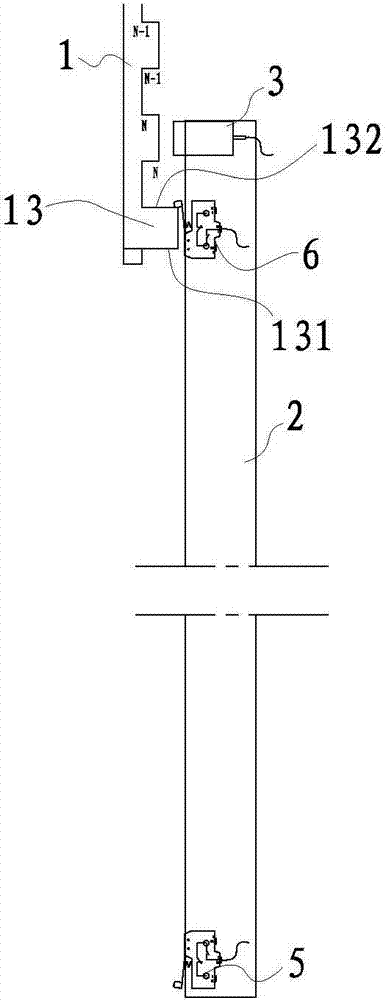

[0034] Embodiment 1: A kind of device that detects the fork height of forklift, such as Figure 1-2 As shown, it includes a plurality of protrusions 11 and depressions 12 evenly spaced along the moving direction of the inner mast and is linked to the rack 1 of the inner mast. The lengths of the protrusions 11 along the moving direction of the inner mast are the same; the depressions 12 The lengths along the moving direction of the inner mast are the same; in general, the lengths of the protrusions 11 and the depressions 12 are the same along the moving direction of the inner mast; in this embodiment, the protrusions 11 and the depressions 12 move along the inner mast The length in the direction is x, and the unit is mm.

[0035] The top of the outer mast 2 is provided with a counter 3 and a check switch 6 sequentially from top to bottom, and the bottom of the outer mast 2 is provided with a reset switch 5 .

[0036] The lower end of the rack 1 has a trigger bump 13, and the u...

Embodiment 2

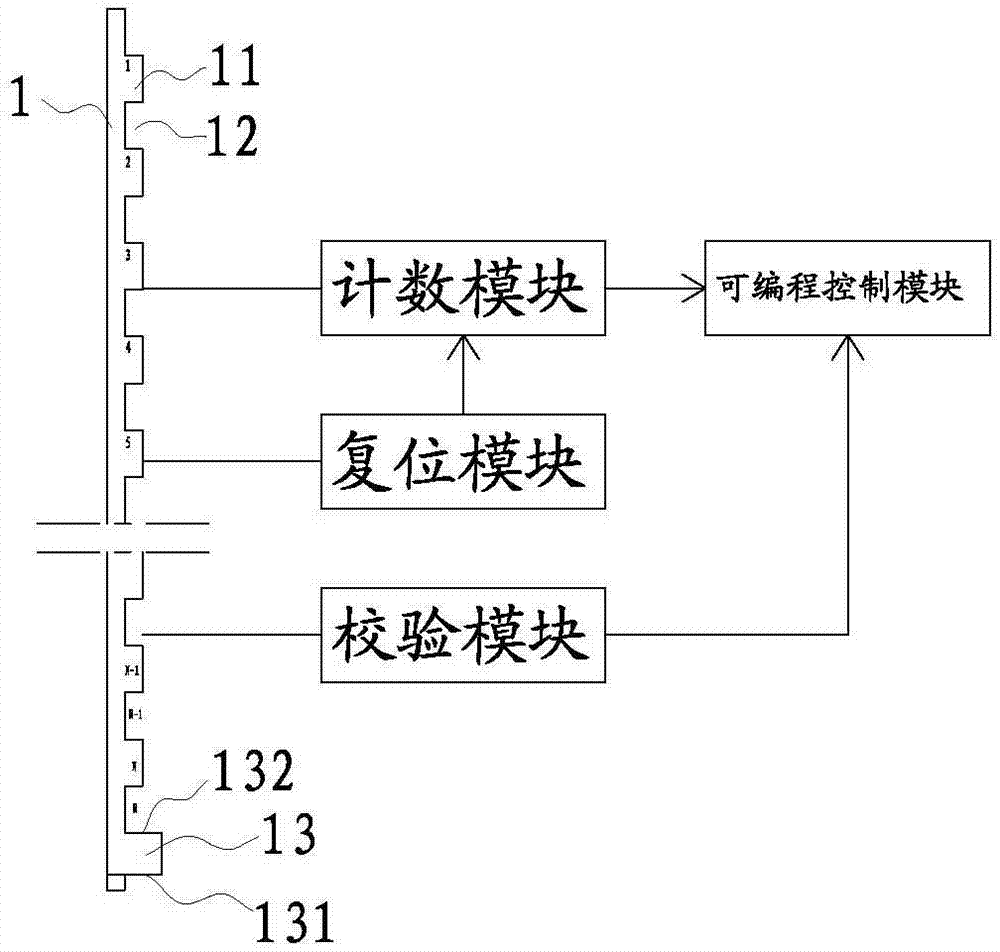

[0041] Embodiment 2: A system for detecting the fork height of a forklift, such as image 3 shown, including

[0042] A plurality of protrusions 11 and depressions 12 are evenly spaced along the moving direction of the inner mast and are linked to the rack 1 of the inner mast;

[0043] The counting module is used to detect the number of protrusions 11 and / or depressions 12 that have reached and passed the counting module during the movement of the rack 1;

[0044] The reset module is triggered by the reset trigger terminal 131 on the rack 1 to reset and initialize the counting module;

[0045] The verification module is triggered by the verification trigger terminal 132 on the rack 1 to trigger the verification instruction;

[0046]The programmable control module receives the information sent by the counting module to calculate the current fork height value and receives the verification instruction sent by the verification module to verify the current fork height value;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com