Compound type sludge dewatering conditioner and application method thereof

A technology of sludge dewatering and application method, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., to achieve the effect of simple conditioning process, promotion of hydrolysis, and realization of sludge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Composite sludge dehydration conditioner.

[0023] The composite sludge dehydration conditioner includes the following components in parts by weight: 4 parts of ferric chloride, 5 parts of calcium oxide, 1 part of magnesium oxide, 1 part of sodium dodecylbenzoate, 3 parts of cetyl tri Methylammonium chloride, 2 parts sulfuric acid.

Embodiment 2

[0024] Example 2 Composite sludge dehydration conditioner.

[0025] The composite sludge dehydration conditioner includes the following components in parts by weight: 5 parts of ferric chloride, 4 parts of calcium oxide, 2 parts of magnesium oxide, 0.5 parts of sodium dodecylbenzoate, 1.5 parts of cetyl tri methyl ammonium chloride, 1 part sulfuric acid.

Embodiment 3

[0026] Example 3 A composite sludge dehydration conditioner is used for sludge treatment.

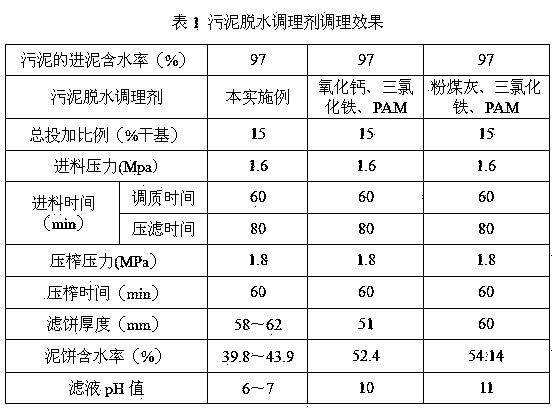

[0027] Taking the primary sludge and activated sludge with a water content of 97% as the treatment object, add sodium dodecylbenzoate accounting for 2% of the weight of the dry basis of the sludge and 1% by weight of cetyltrimethylammonium chloride, stirred, and the reaction was adjusted for 20 minutes; then add iron trichloride accounting for 5% of the weight of the sludge dry basis, and 4% of the weight of the oxidation of the sludge dry basis. Calcium, magnesium oxide accounting for 1% by weight of the dry basis of sludge, stirring, and adjusting the reaction for 30 minutes; then adding sulfuric acid accounting for 2% by weight of the dry basis of sludge, stirring, and adjusting the reaction for 10 minutes; The filter press performs deep sludge dehydration, and the filter area of the filter press is 1.8~3 m 2 , The effective volume is 0.054m3, the filtration pressure is ≤1.8M Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com