Winter wheat slow release fertilizer and preparation method thereof

A slow-release fertilizer and winter wheat technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of imbalanced soil nutrient balance, large differences in fertilization levels, and large labor input, so as to improve yield and quality, and improve economic efficiency. Benefits and ecological benefits, the effect of reducing the cost of fertilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

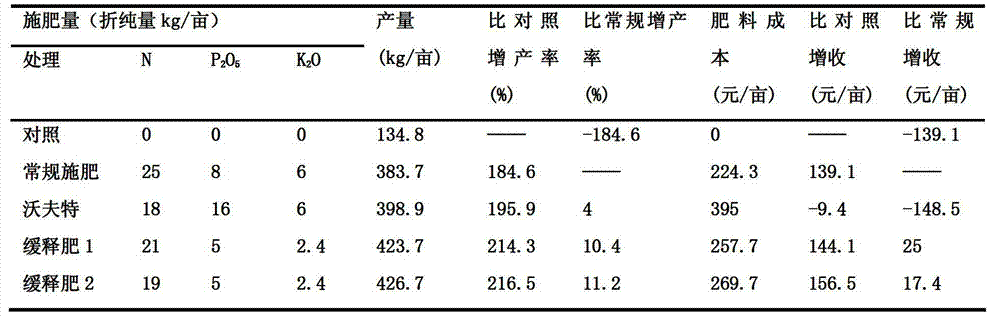

Examples

Embodiment 1

[0014] According to the configuration of 100kg of slow-release fertilizer, 46kg of urea, 41kg of ordinary calcium superphosphate, 4kg of potassium chloride, 1.8kg of dicyandiamide, 4.2kg of humic acid, 3kg of diatomaceous earth or clay, the above raw materials After being crushed to 40-60 mesh, mixed evenly, granulated with a disc granulator, dried with a tumble dryer and made into a 100kg winter wheat clean production slow-release fertilizer after drying.

[0015] Application method: Spread evenly before sowing combined with soil preparation, rotate or rake the field after spreading, or use a fertilizer machine to sow into the soil, and the rate of application per mu is 100kg. This fertilizer is a one-time base application, and no topdressing fertilizer will be applied in the future.

Embodiment 2

[0017] According to the configuration of 100kg of slow-release fertilizer, 41kg of urea, 41kg of ordinary calcium superphosphate, 4kg of potassium chloride, 2.5kg of dicyandiamide, 6.5kg of humic acid, and 5kg of diatomaceous earth or clay. After the above-mentioned raw materials are crushed to 40-60 mesh, mixed evenly, granulated and dried, the finished product of winter wheat clean production slow-release fertilizer is obtained.

[0018] The application method is the same as in Example 1.

[0019] The slow-release fertilizer of the present invention is characterized in that it is a clean production fertilizer developed according to the nutrient characteristics of farmland in the Yellow River irrigated area and the growth characteristics of winter wheat in Ningxia. It is suitable for the planting and application of winter wheat in the Yellow River irrigated area. Compared with the prior art, it has the following advantages:

[0020] ① Simplify fertilization (fool fertilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com