Sulfur element containing bicycloimidazoline derivant corrosion inhibitor

A bicyclic imidazoline derivative technology, applied in the field of bicyclic imidazoline derivative corrosion inhibitors, can solve problems affecting oilfield production, threats to popularization and application, shutdown and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

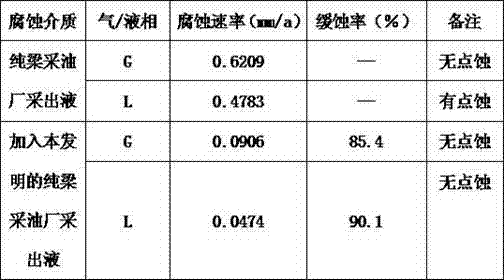

Examples

Embodiment Construction

[0009] For further disclosing the technical scheme of the present invention, the following are described in detail by the examples:

[0010] A bicyclic imidazoline derivative corrosion inhibitor containing sulfur elements, comprising 60% of the total mass fraction ~ 90% bicyclic imidazoline derivatives containing sulfur elements and 10% of the total mass fraction ~ For the solubilizer of 40, put the two kinds of raw materials into the reaction kettle successively according to the above ratio, stir them evenly at 80°C, and then discharge the material after cooling to make a bicyclic imidazoline derivative corrosion inhibitor containing sulfur elements.

[0011] The bicyclic imidazoline derivatives containing sulfur elements include fatty acids and diethylenetriamine. The fatty acids and diethylenetriamine react in the reactor. The fatty acids account for 60-80 parts by mass of the total, and diethylenetriamine accounts for 20-40, in this reaction, xylene is used as a water-car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com