Rectangular steel pipe concrete column steel beam lower bolt upper welding outer rib annular plate node construction method

A technology of concrete columns and rectangular steel pipes, which is applied in construction, building structure, and processing of building materials, etc., can solve the problems of very high installation and positioning accuracy, difficult construction, and high cost, and achieves the promotion of assembly process, shortening construction period, The effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

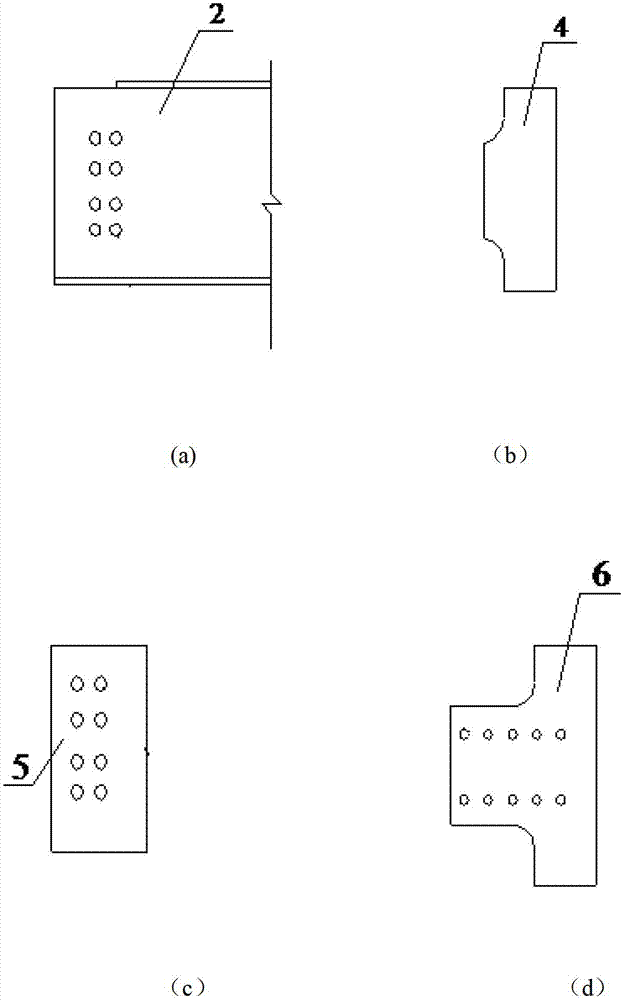

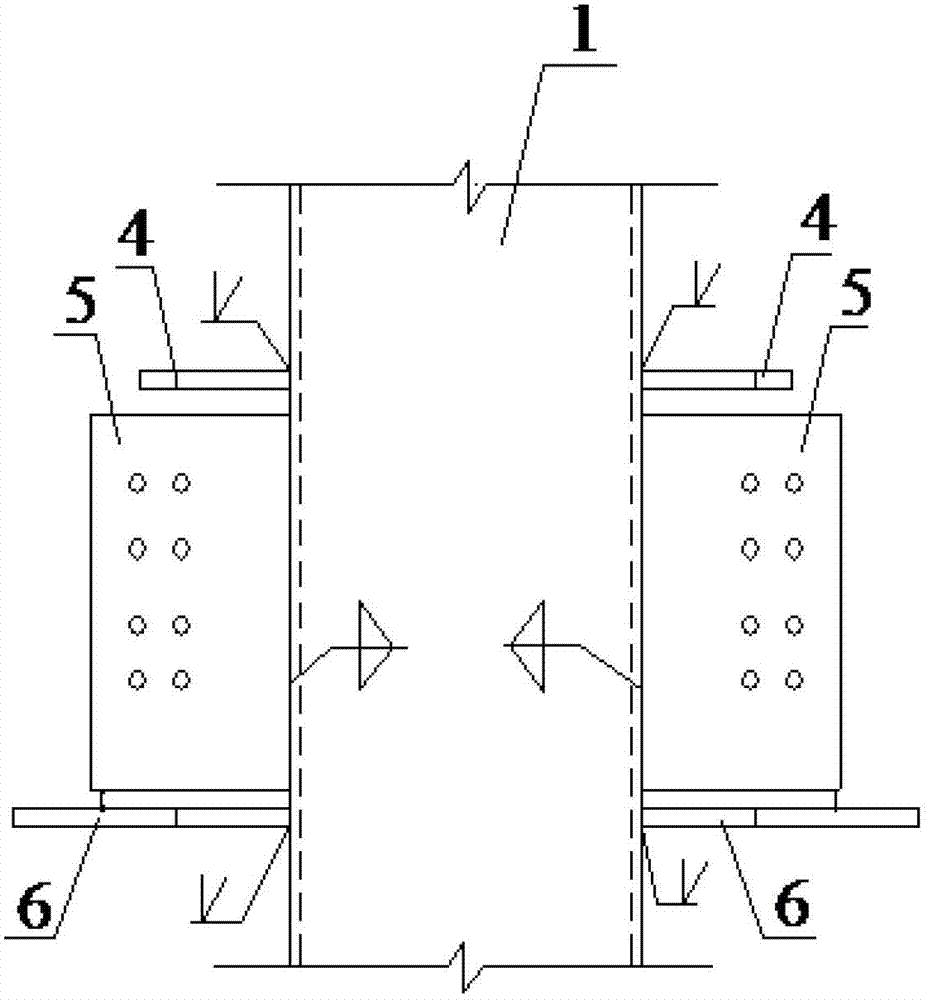

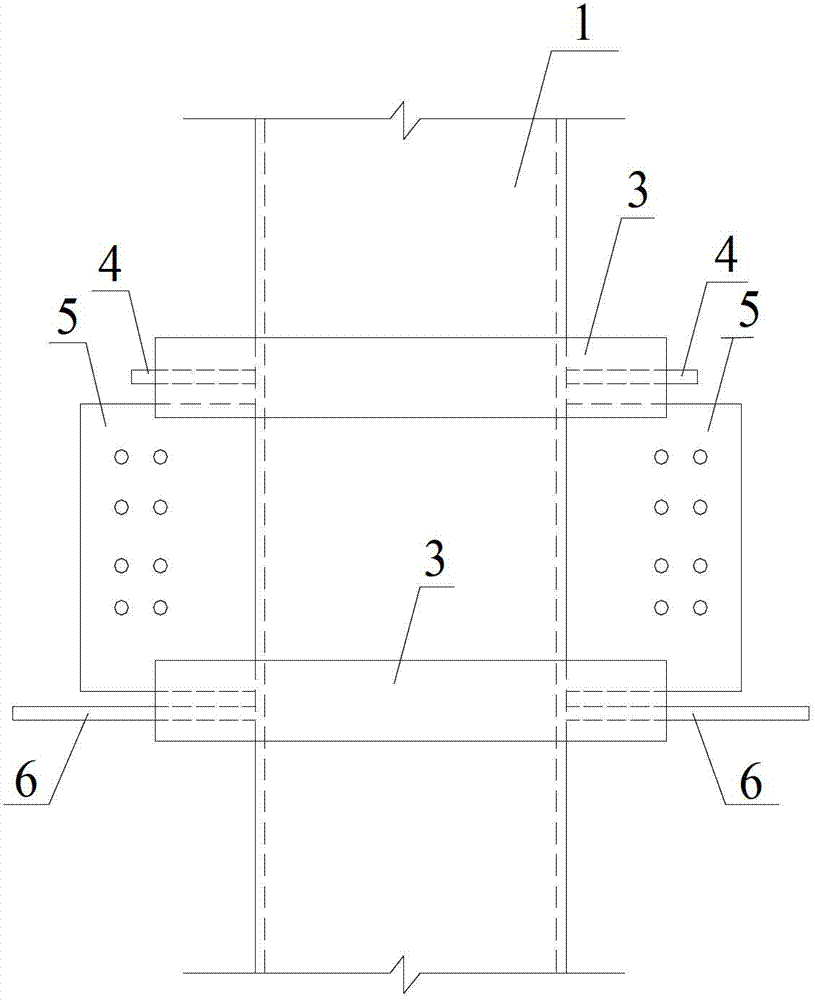

[0035] The present invention proposes a rectangular steel tube concrete column-H-shaped steel beam lower bolt upper welding outer rib ring plate connection node and construction method, which consists of the following parts: rectangular steel tube concrete column 1, H-shaped steel beam 2, vertical ribs 3. Upper outer ring plate 4, web connecting plate 5, lower outer ring plate 6, high-strength bolts 7, T-shaped ribs 8. For details of the more complex components, see figure 1 .

[0036] If there are only beams in one direction, implement as follows:

[0037] . The end of the H-shaped steel beam 2 and the vertical rib 3 are only a rectangular steel plate processed in the factory according to the drawing figure 1 , wherein the thickness of the web connection plate 5 should not be less than the thickness of the web of the steel beam, and the thickness of the upper outer ring plate 4 and the lower outer ring plate 6 should not be less than the thickness of the steel beam flange.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com