A self-defined adjustment method and device for water treatment multi-way valve station and flow rate

An adjustment method and water treatment technology, applied in the valve operation/release device, valve device, valve details, etc., can solve the problems of unadjustable flow cross-sectional area, unadjustable station flow, etc., to improve the utilization rate of water, The effect of prolonging the service life of the equipment and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

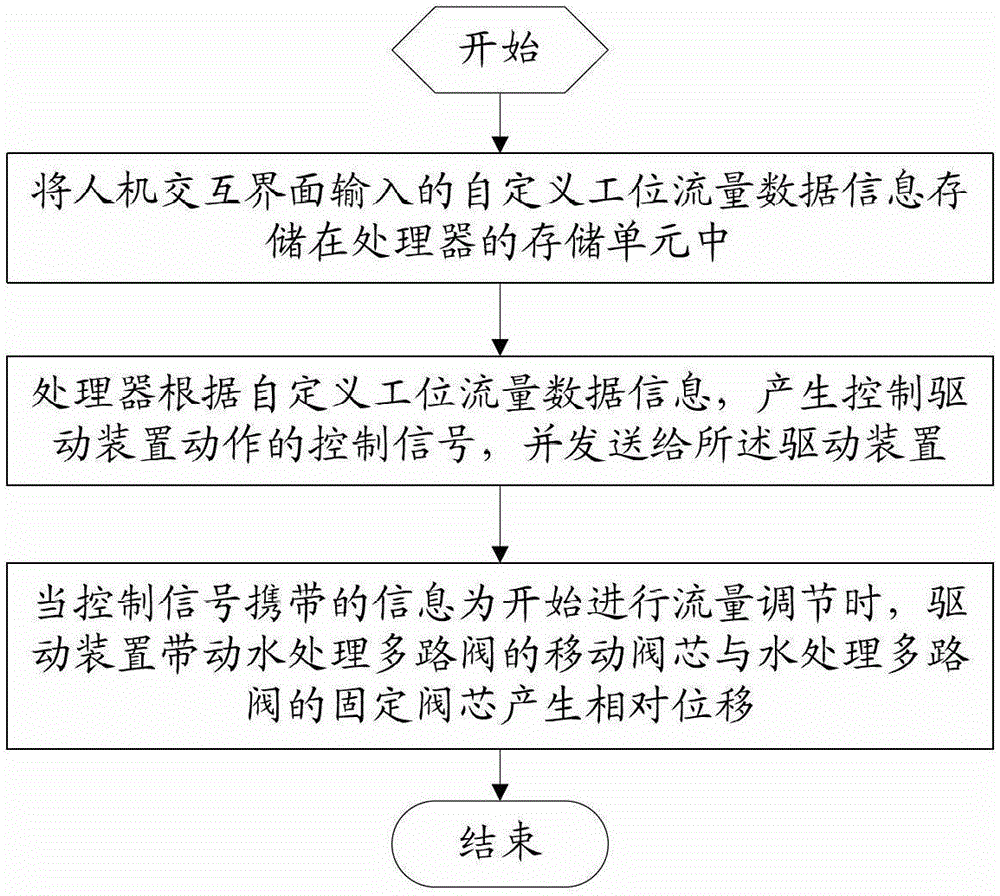

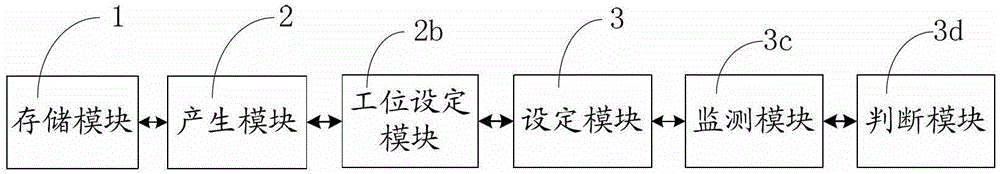

[0055] Such as figure 1 As shown, a self-defined adjustment method for the position and flow of a water treatment multi-way valve includes the following steps:

[0056] Step 1: Store the flow rate data information of the user-defined station input by the human-computer interaction interface in the storage unit of the processor;

[0057] Step 2: The processor generates a control signal for controlling the action of the driving device according to the flow data information of the self-defined station, and sends it to the driving device;

[0058] Step 3: When the information carried by the control signal is to start flow adjustment, the driving device drives the station water hole on the movable spool of the water treatment multi-way valve to connect with the station water hole on the fixed spool of the water treatment multi-way valve. The hole produces a relative displacement that changes the flow rate of each station, thereby adjusting the flow rate of each station.

[0059] ...

Embodiment 2

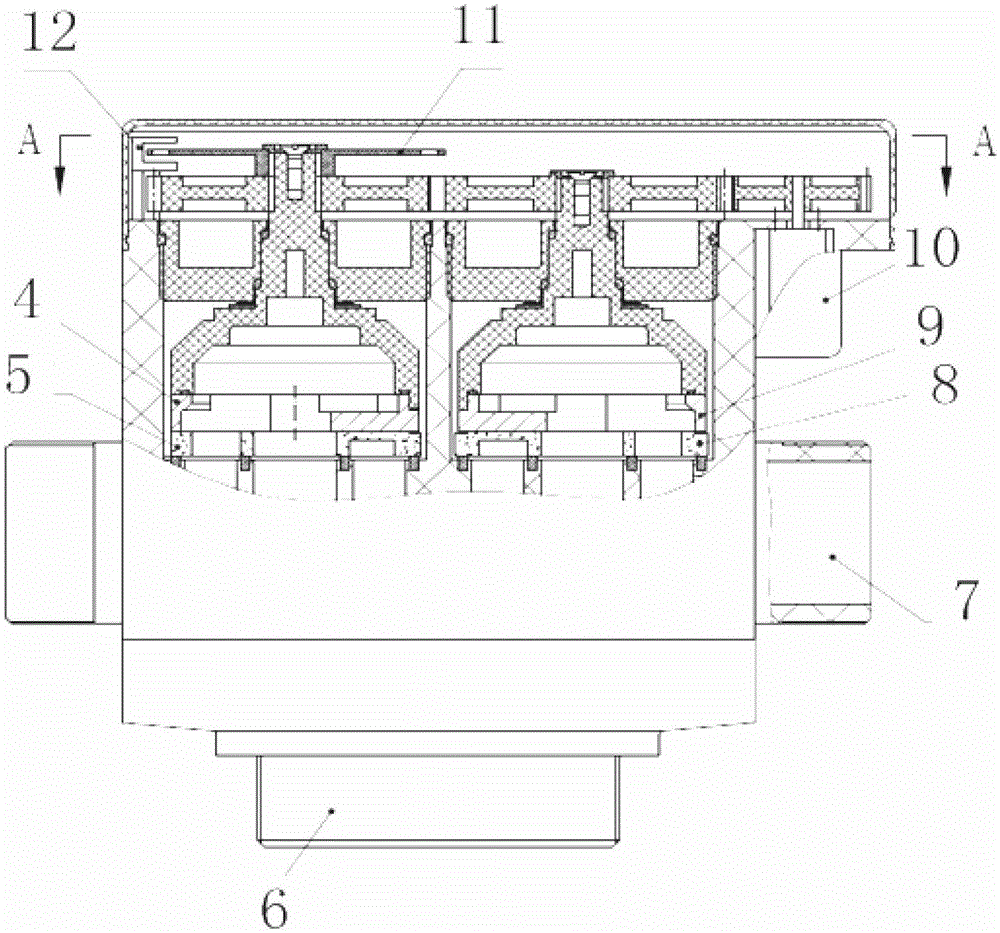

[0089] The difference between this embodiment and embodiment 1 is that, as Figure 5 and Figure 6 As shown, several through holes connected at intervals on the side of the grating rod 14 correspond to the axial displacement of the photocoupler 12 on the valve body, and control the electric transmission to drive the station water hole on the outer circle of the moving valve core. The water hole on the fixed spool hole is connected or closed by axial displacement of variable flow rate.

[0090] Set different backwash water inlet working procedures according to the flow regulator, drive the eccentric shaft on the turntable 15 through the motor 10, move the spool shaft 16 downward to make a small axial displacement, and control the movement of the spool shaft 16 on the outer circle The station water hole, relative to the water inlet hole 7 on the fixed spool hole of the valve body, is connected to the fully open position by axial displacement, and can automatically carry out bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com