Humidification device utilizing heating heat energy

A technology of humidification device and supply device, which is applied in the direction of household heating, air humidification system, ultrasonic humidifier, etc. It can solve the problems of insufficient humidification capacity and low energy consumption, and achieve improved humidification capacity, large power generation, and large temperature difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

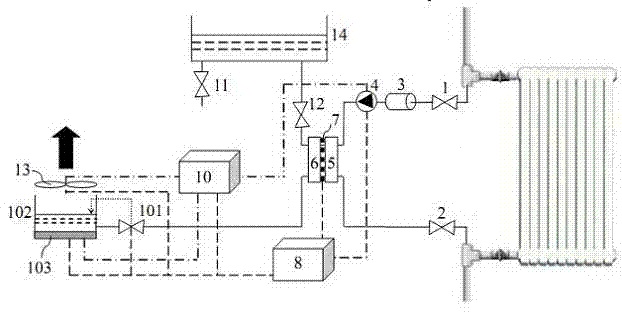

[0024] like figure 1 As shown, a humidification device utilizing heating heat energy is connected to the heating circuit by setting a three-way water inlet in the heating pipeline. The power circulates through the water heater 5 to supply the thermal energy of the hot end surface of the thermoelectric power generation device 7, and is sent back to the heating circuit through the three-way return port through the return valve 2 to realize the heating and hot water circulation; the water storage container 14 is placed at a high position to store water. In the container 14 is humidified feed water, the humidified feed water flows through the water cooler 6 through the water supply valve 12 to cool the cold end face of the thermoelectric power generation device 7, and at the same time its own temperature rises to achieve preheating, and then sent to the humidification container 102 through the pipeline to humidify. The position of the container 102 relative to the water storage co...

Embodiment 2

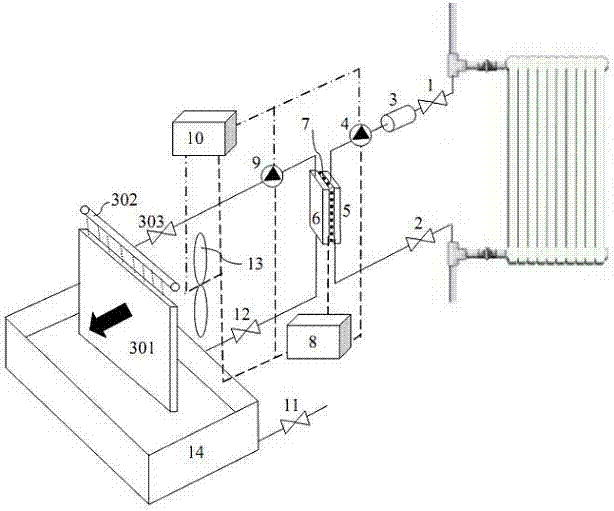

[0028] like image 3 As shown in the figure, a humidifying device using heating heat energy is connected to the heating circuit by setting a three-way water diversion port in the heating pipeline. The heating hot water passes through the water diversion valve 1, filters impurities through the filter 3, and is supplied by the heating hot water circulation pump 4 The power circulates through the water heater 5 to supply the heat energy on the hot end surface of the thermoelectric power generation device 7, and sends it back to the heating circuit through the water return valve 2 through the three-way water return port to realize the circulation of hot water for heating; the water storage container 14 is humidification feed water, humidification The feed water flows through the water supply valve 12 and flows through the water cooler 6 to cool the cold end surface of the thermoelectric power generation device. At the same time, its own temperature rises to realize preheating, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com