Engine cooling inclined hole detection tool and detection method based on the same

A technology for engine cooling and inspection tools, used in mechanical diameter measurement, mechanical depth measurement, mechanical roughness/irregularity measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

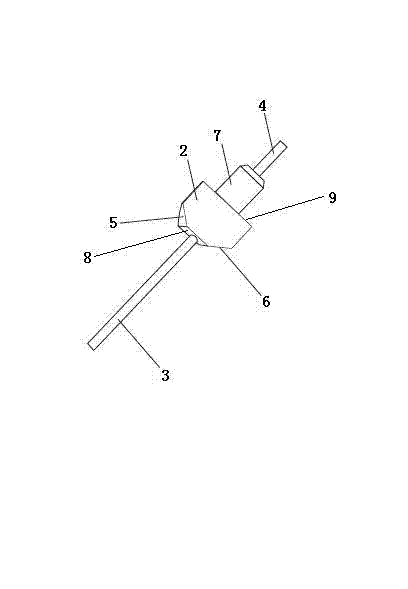

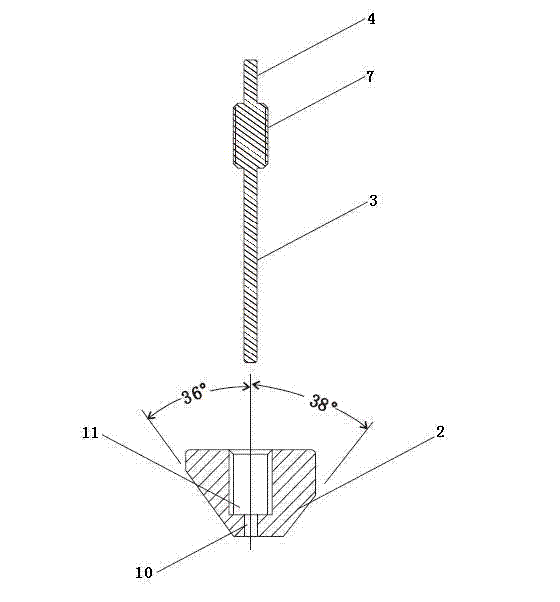

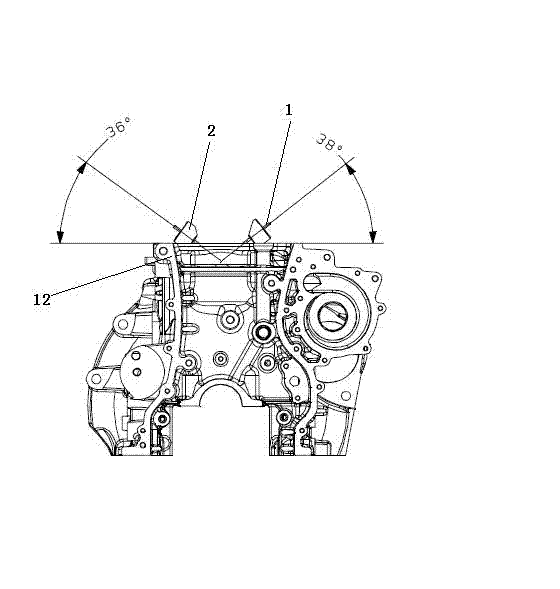

[0028] like figure 1 , figure 2 and image 3As shown in the figure, an engine cooling slant hole detection tool is specially used for the slant hole detection of an engine block adopting a double cooling slant hole cooling method. On the engine block 12, there are two cooling slant holes communicating with each other at the bottom as the flow channel of the coolant. The design requires that the diameter of the slant holes is between 2.9mm and 3.0mm, and the inclination angles of the two slant holes are respectively 36° and 38°, the depth of the 36° oblique hole is 36mm to 37mm, and the depth of the 38° oblique hole is 37mm to 38mm. The engine cooling oblique hole detection tool includes a measuring stick 1 and an angle block 2. The measuring stick 1 and the angle block 2 are detachably connected. In this embodiment, it is specifically a composite connection method of sliding socket and screw connection. The measuring rod 1 includes an oblique hole through-end detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com