Method for testing geometric parameters of optical fiber coating layers

A technology of geometric parameters and detection methods, applied in measurement devices, optical devices, instruments, etc., can solve the problems of inability to meet the requirements of optical fiber manufacturers, poor test stability performance, and low test accuracy, and improve test speed and test accuracy. Accuracy, improved test speed, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

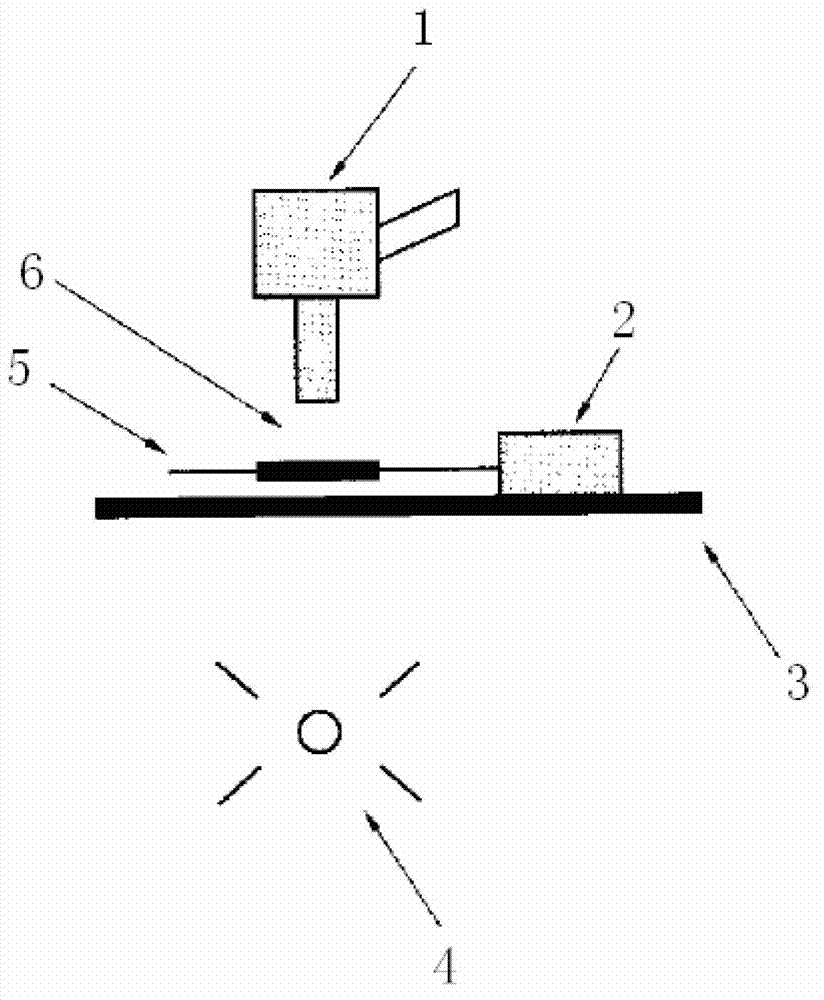

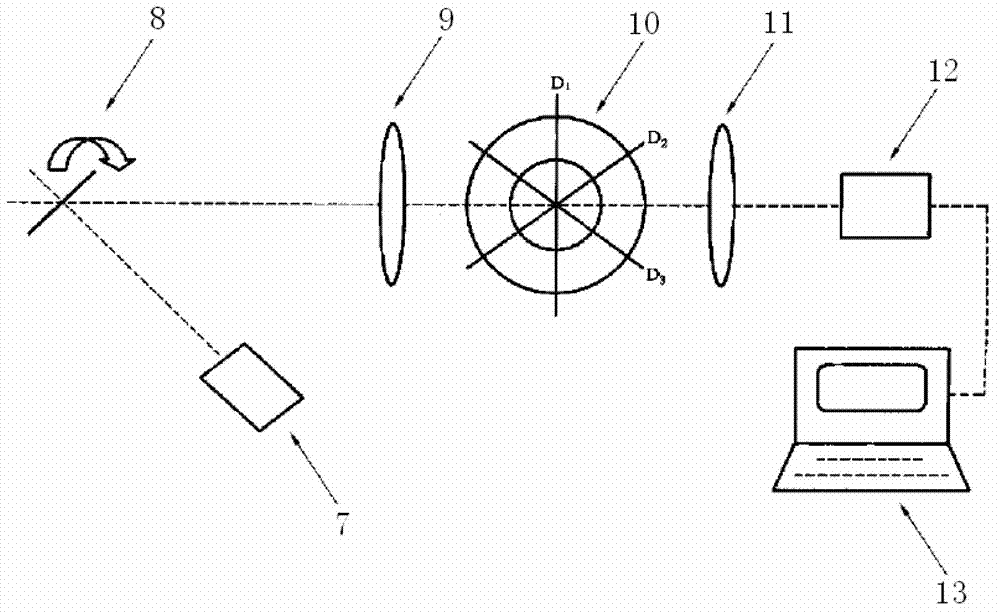

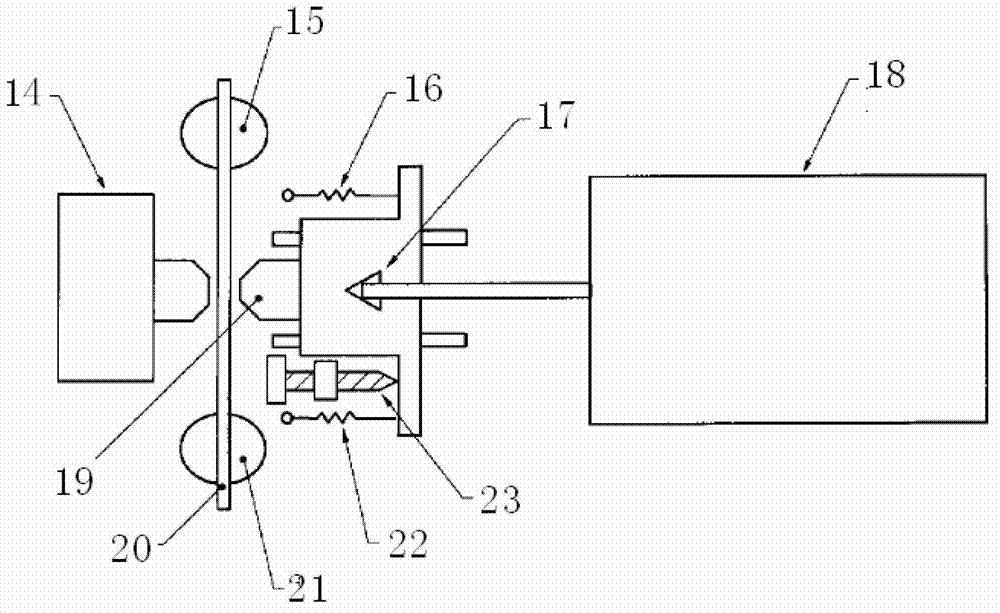

[0061] Test the parameters of the optical fiber through the following steps:

[0062] (1) Peel off the coating layer after the end face of the optical fiber coating layer, and then use a light source to illuminate from the stripped place;

[0063](2) The light source passes through the conduction of the coating layer to illuminate the end face of the fiber coating layer;

[0064] (3) Project the image of the end face of the optical fiber coating to the CCD imaging system, and the image acquisition system collects the image,

[0065] Through the different material attenuation coefficients of each coating layer and different light incident angles, each layer can be distinguished, and then the coating diameter and coating layer of each coating layer of the optical fiber coating layer can be calculated through the image processing system. Coating out-of-roundness, minimum (maximum) coating thickness, coating\core concentricity error and other parameters.

[0066] The design spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com