Wiring automatic check system and method

An automatic inspection and wiring technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of signal interpretation errors, omissions, errors, time-consuming and laborious, and achieve the effect of preventing signal interpretation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

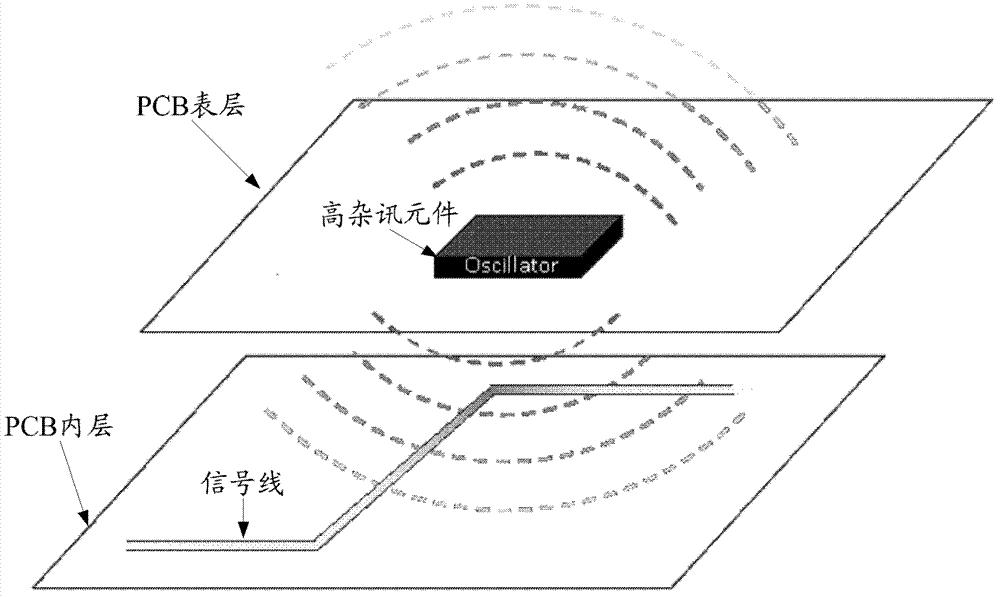

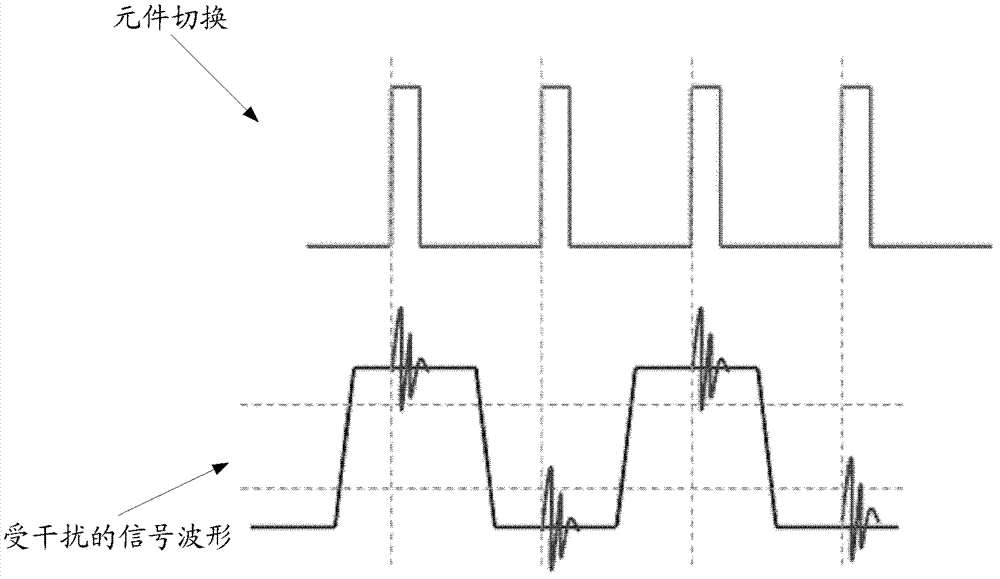

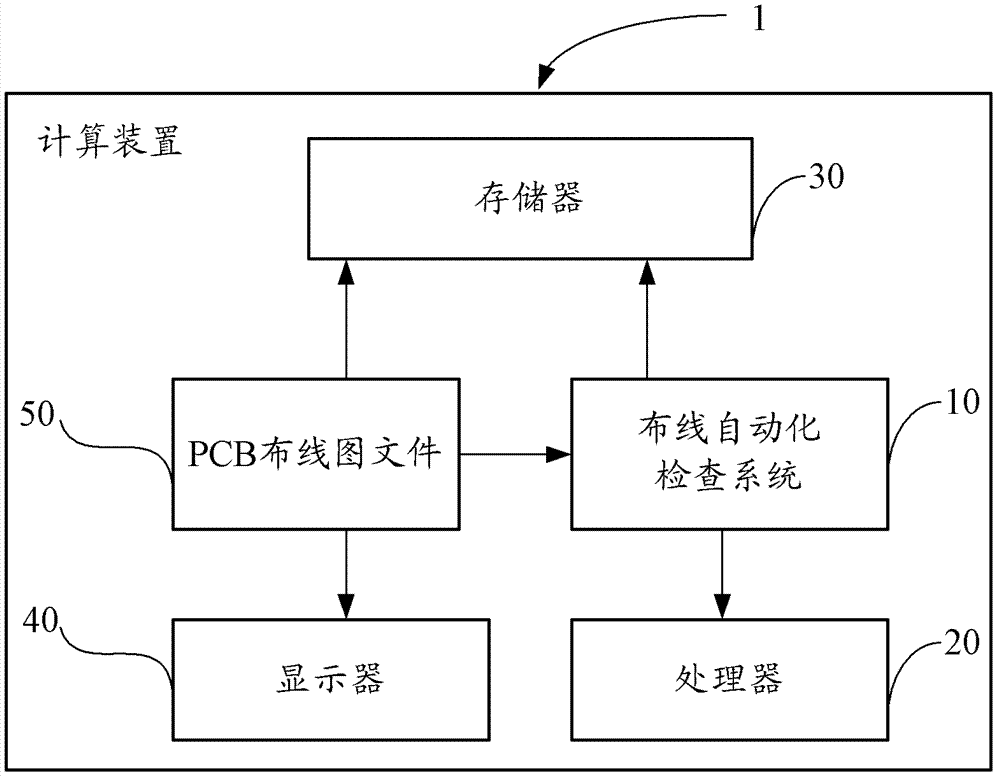

[0017] refer to figure 2 Shown is an application environment diagram of a preferred embodiment of the automatic wiring inspection system of the present invention. The automatic wiring inspection system 10 is applied in the computing device 1 . The computing device 1 further includes a processor 20 , a memory 30 , a display 40 and a printed circuit board (printed circuit board, PCB) wiring diagram file 50 . The automatic wiring inspection system 10 is used to screen out signal lines interfered by high-noise components in the PCB layout file 50, so that engineers can modify the wiring and prevent signal interpretation errors caused by electromagnetic interference of high-noise components. PCBs generally consist of multi-layer circuit boards, such as component layers and wiring layers. Usually, the component layer is located on the surface layer of the PCB, while the wiring layer is located on the inner layer of the PCB. When the signal line, especially the high-speed signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com