A real-time information-driven intelligent navigation method for manufacturing activities at the production equipment end

A technology of production equipment and real-time information, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve the problems of lack of real-time production status information on the equipment side, production operation guidance, unfavorable dynamic optimization results, and difficult dynamic optimization, etc., to achieve Improve timeliness, reduce stagnation and waiting time, and solve the effect of slow real-time response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment and accompanying drawing, the present invention is described in further detail:

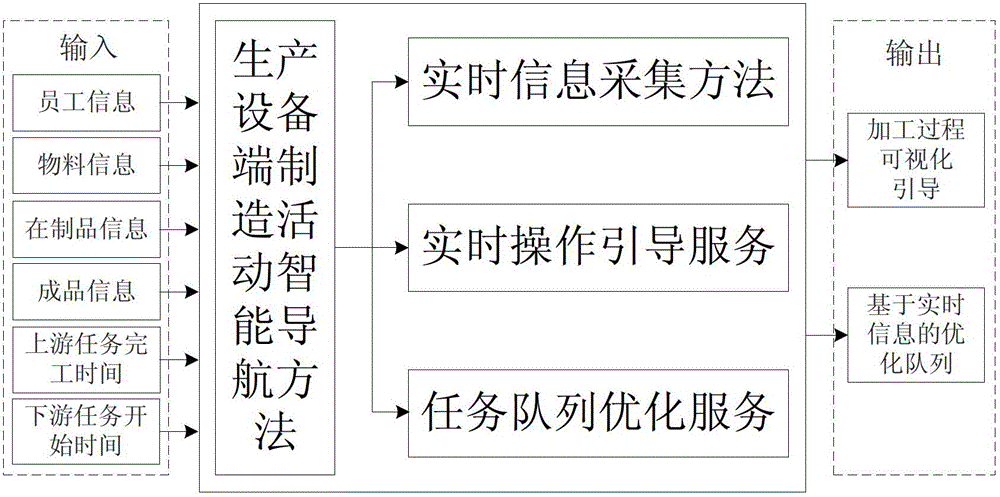

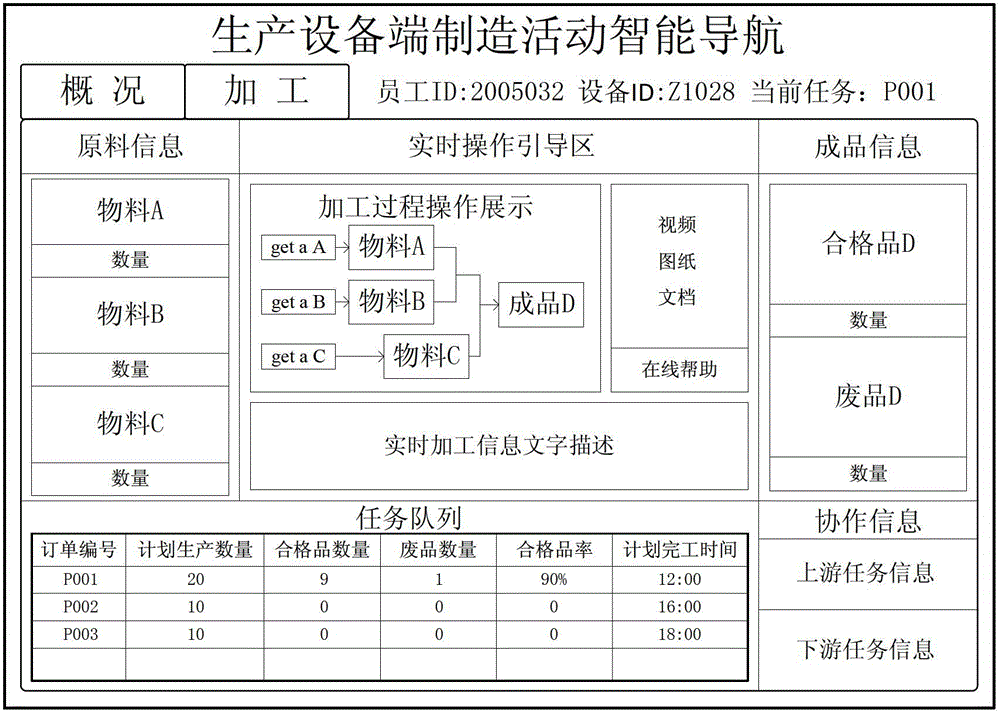

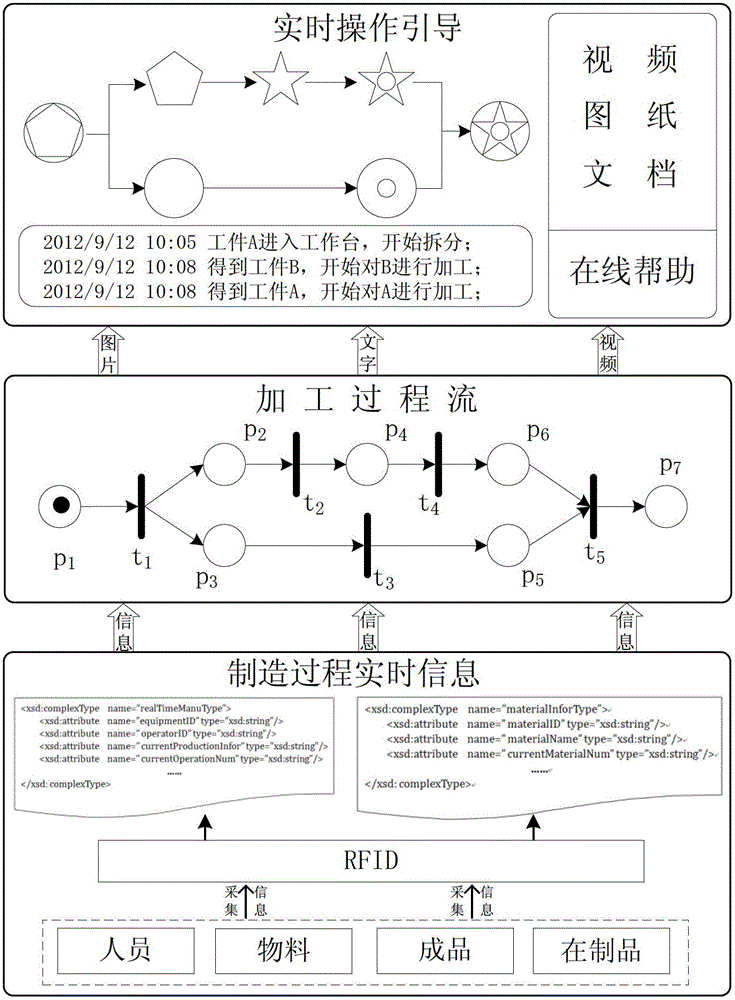

[0037] see figure 1 , the real-time information-driven intelligent navigation method for manufacturing activities at the production equipment side in this embodiment aims to collect multi-source manufacturing information (including employee information, material information, work-in-progress information, finished product information, upstream Task completion information, downstream process start information) as input, by providing real-time operation guidance services for manufacturing activities and task queue optimization services, output real-time information-driven visual guidance for the processing process on the production equipment side, so as to reduce errors caused by improper operations or materials. Quality problems caused by loading; output optimized queues based on real-time information to reduce stagnation of WIP and improve the fluency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com