Liquid crystal display, light-emitting diode (LED) backlight and driving method thereof

A technology of LED backlight and liquid crystal display, applied in static indicators, instruments, optics, etc., can solve problems such as high discharge voltage, temperature rise, and poor discharge characteristics, and achieve high conversion efficiency, low burnout, and low power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures. In the following description, unnecessary detailed descriptions of well-known structures and / or structures may be omitted in order to avoid obscuring the inventive concept caused by unnecessary detailed descriptions of well-known structures and / or functions.

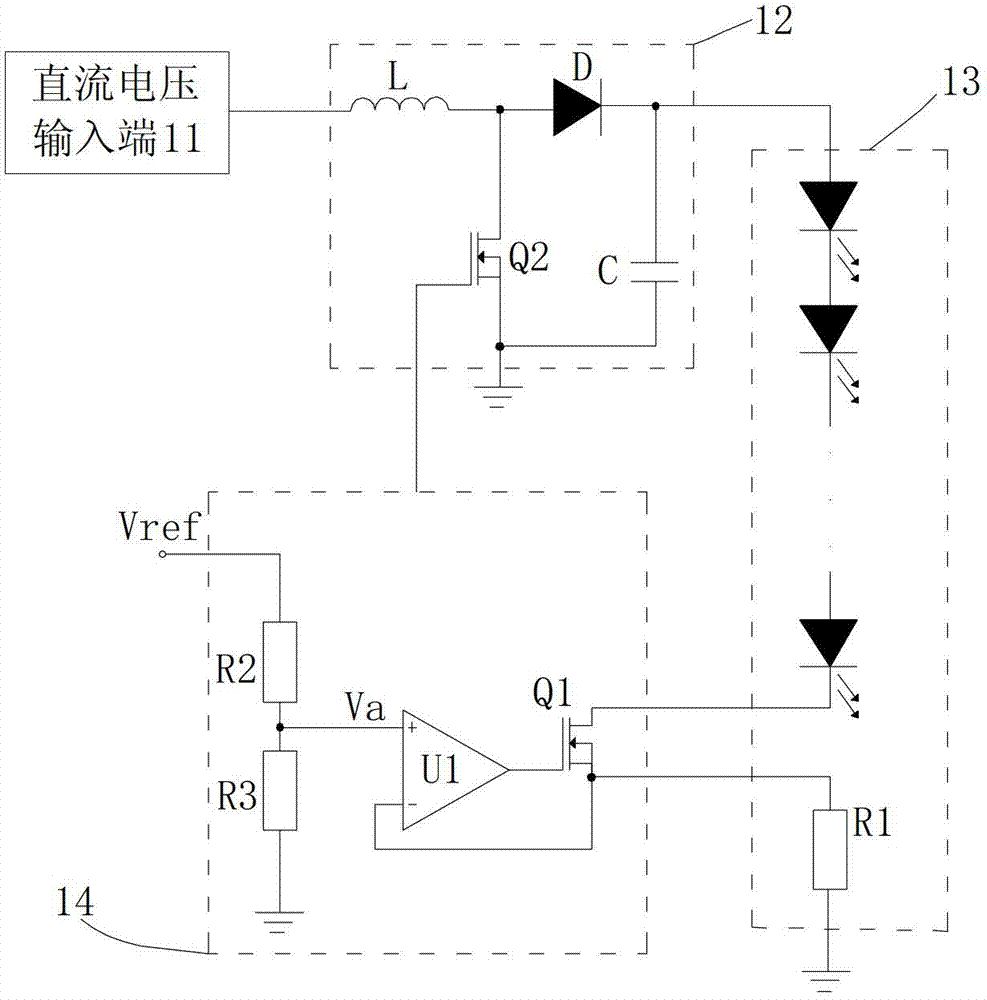

[0019] figure 1 An LED backlight for a liquid crystal display according to an embodiment of the present invention is shown.

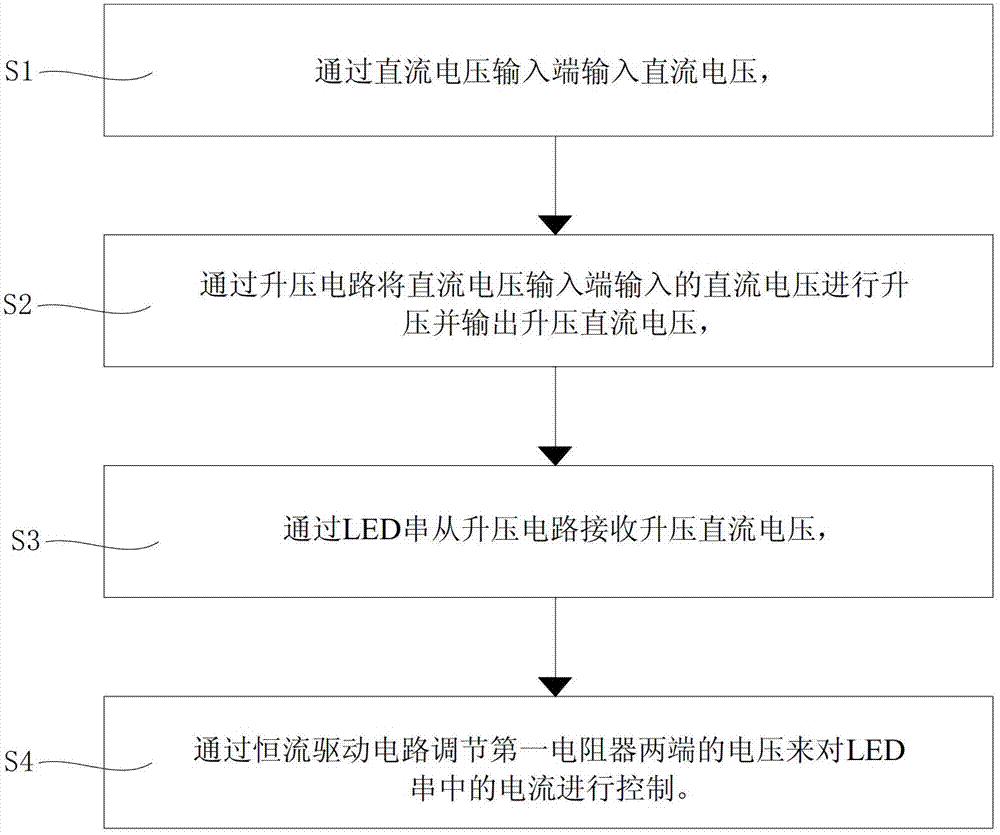

[0020] Such as figure 1 As shown, the LED backlight according to the embodiment of the present invention includes a DC voltage input terminal 11 , a boost circuit 12 , an LED string 13 and a constant current drive circuit 14 .

[0021] The DC voltage input terminal 11 is used for inputting a DC v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com