Cooling system for photovoltaic power generation module

A photovoltaic power generation and component technology, which is applied in the photovoltaic field, can solve the problems of high temperature of photovoltaic power generation components, heat is not recycled, and sunlight efficiency is low, so as to reduce temperature, avoid heat loss and waste, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

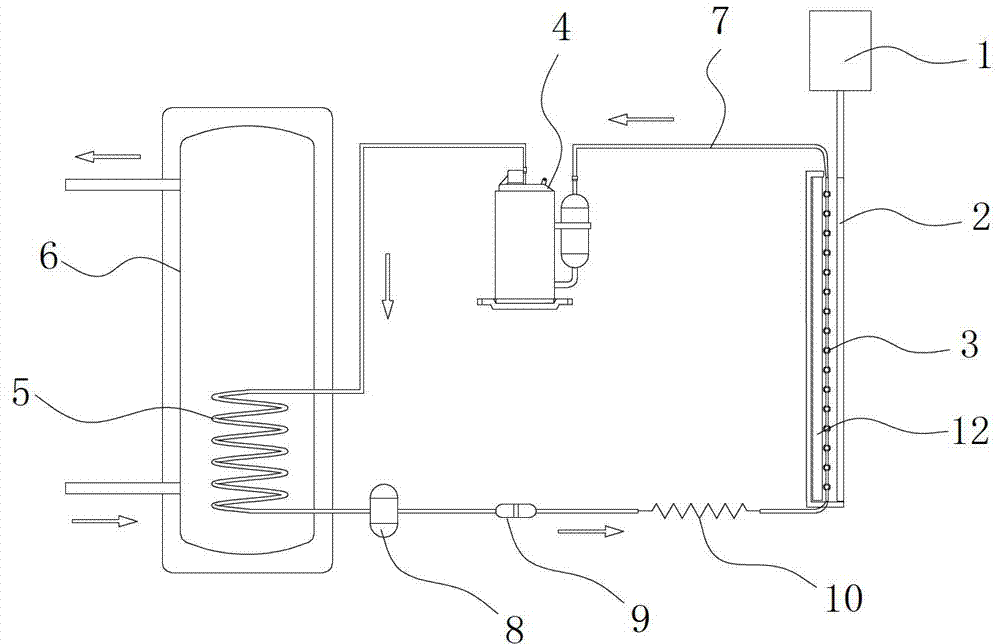

[0022] like figure 1 As shown, a photovoltaic power generation component cooling system described in this embodiment includes a photovoltaic power generation component 1, a heat absorption plate 3 is arranged on one side of the photovoltaic power generation component 1, and a working medium is arranged in the heat absorption plate 3 channel, the heat absorbing plate 3 communicates with a compressor 4 and the heat exchange device through a working medium conduit 7 to form a circuit, the photovoltaic power generation module 1 includes a photovoltaic panel 2, and the heat absorbing plate 3 is arranged on the One side of the photovoltaic panel 2. The heat absorbing plate 3 is arranged below the photovoltaic panel 2 and both overlap up and down, and a heat insulating plate 12 is arranged under the heat absorbing plate 3, and the heat insulating plate 12 can be supported on a fixed shell superior.

[0023] The heat exchange device includes a condenser 5, and the condenser 5 is arr...

Embodiment 2

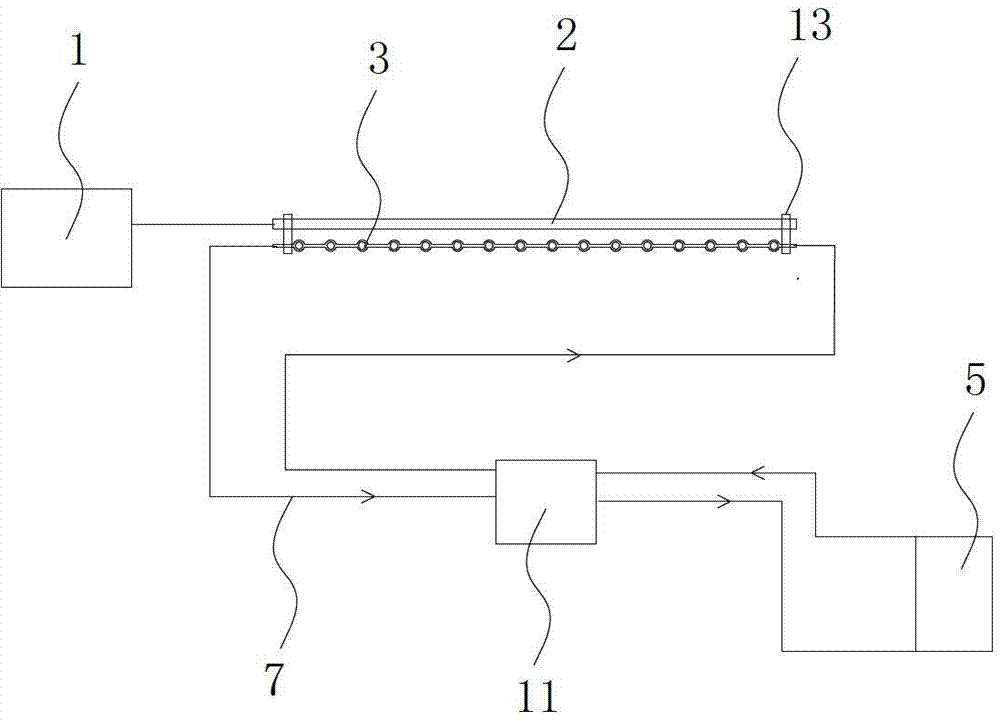

[0025] like figure 2 As shown, the heat absorbing plate 3 of the technical solution is arranged under the photovoltaic panel 2 and the two are fixed to each other by a positioning member 13. The liquid storage tank 8, the filter 9, the throttling element 10 and the compressor 4 It is integrated into a circulation main engine 11, and the circulation main engine 11 is arranged on the two working medium conduits 7 respectively connected with the inlet and outlet of the heat exchange device. The heat exchange device of this technical solution is a condenser 5.

Embodiment 3

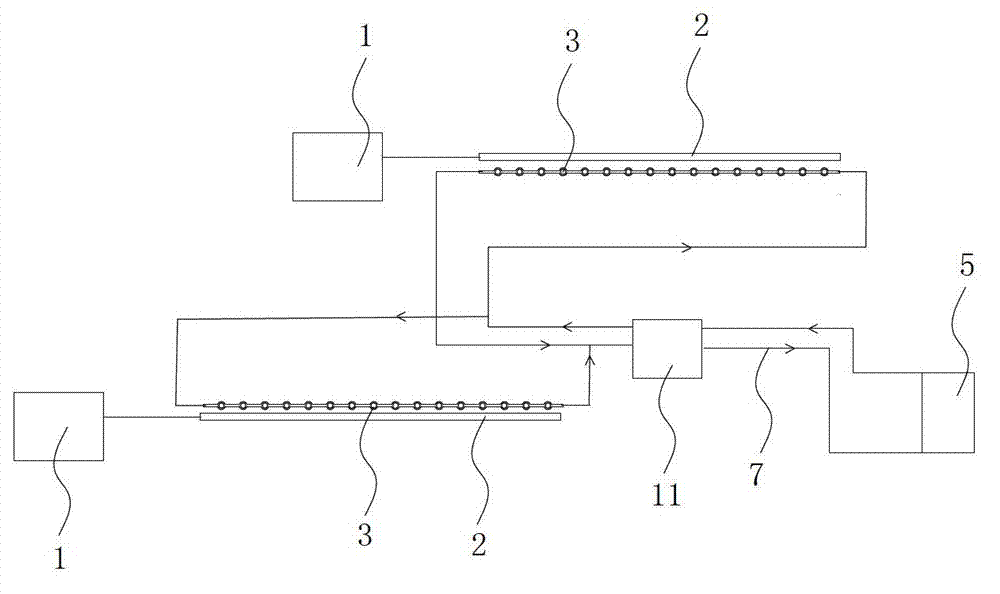

[0027] like image 3 As shown, in order to improve the utilization rate of the system, the circuit of this technical solution includes a main circuit and a plurality of parallel branches branched by the main circuit, and each branch is provided with a heat absorbing plate 3 . The compressor 4 and the heat exchange device are arranged on the main road.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com