Method for manufacturing magnesium alloy colorless transparent film and product with the same

A manufacturing method and technology of magnesium alloys, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of poor corrosion resistance and difficulty in maintaining the appearance of the metal, and achieve the effect of satisfying corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

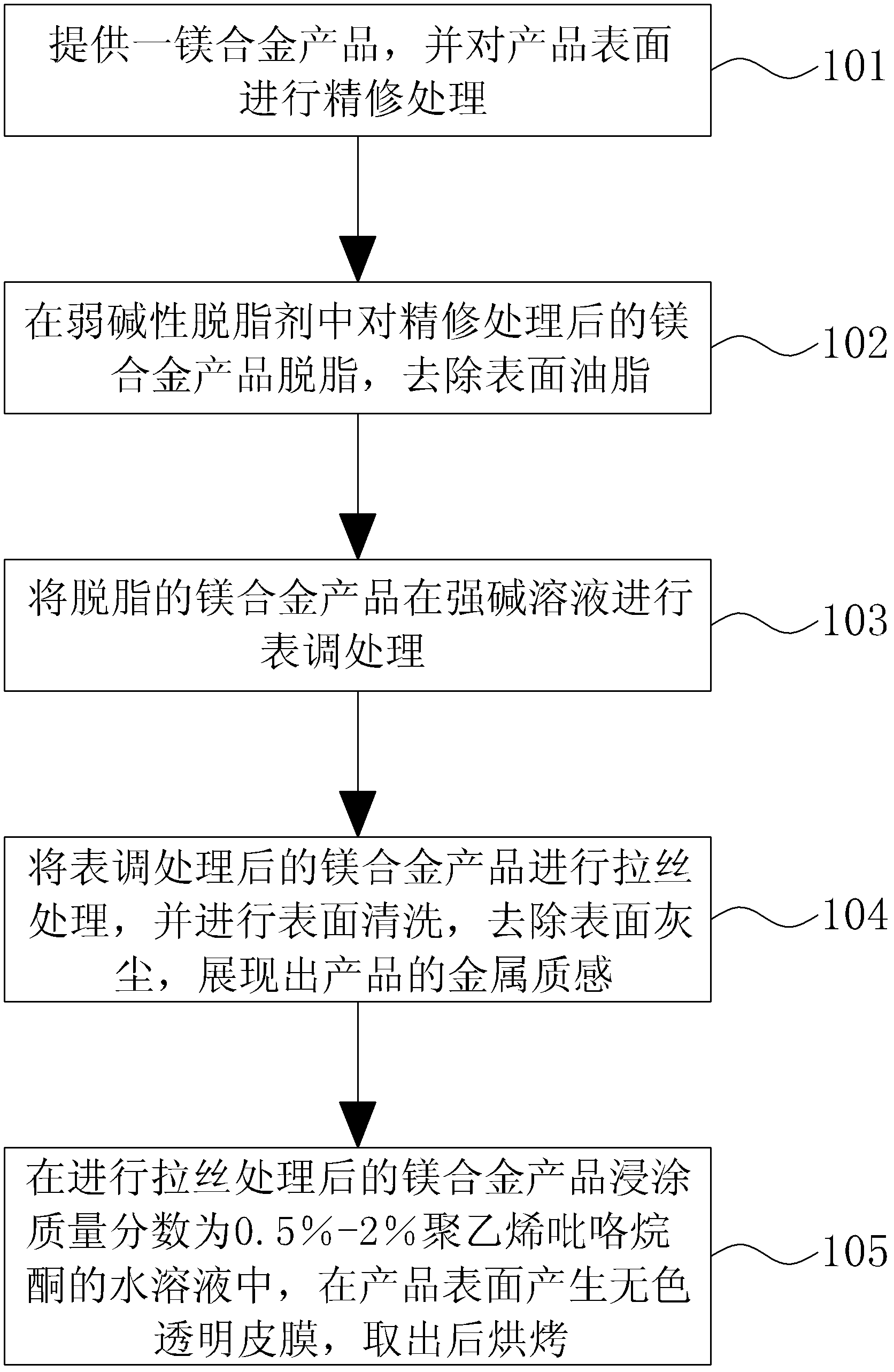

[0023] For a further understanding of the purpose of the present invention, method steps and functions, please refer to figure 1 , and detailed as follows:

[0024] In order to achieve the above object, the present invention provides a kind of manufacturing method of magnesium alloy colorless transparent film, and it comprises the following steps:

[0025] Step 101: providing a magnesium alloy product, and finishing the product surface;

[0026] Step 102: Degrease the refined magnesium alloy product in a weak alkaline degreasing agent to remove surface grease;

[0027] Step 103: surface-conditioning the degreased magnesium alloy product in a strong alkali solution;

[0028] Step 104: Perform wire drawing on the surface-conditioned magnesium alloy product, and perform surface cleaning to remove surface dust and show the metal texture of the product;

[0029] Step 105: Dip coating the wire-drawn magnesium alloy product in an aqueous solution with a mass fraction of 0.5%-2% po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com