Mold and method for sectionally adjusting cooling efficiency of the mold

A mold cooling and segmentation technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as uneven cooling, limited mold shape design, and inability to form mechanical products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

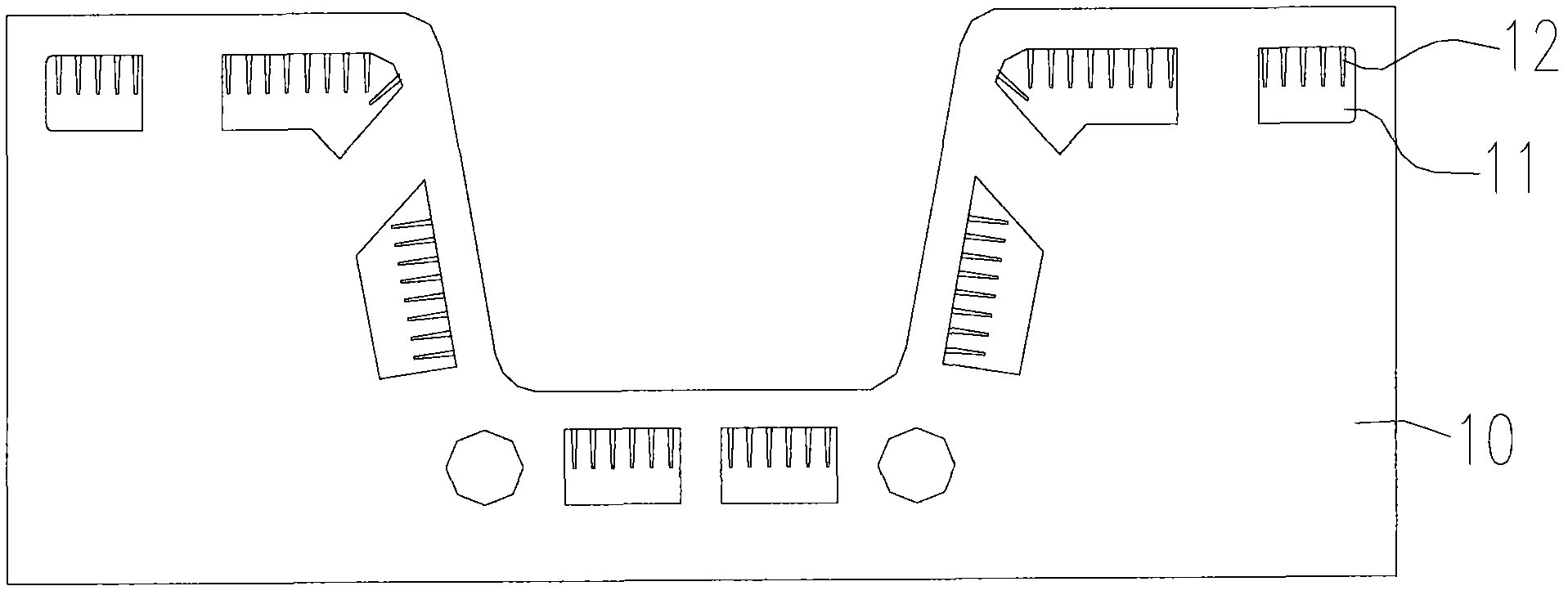

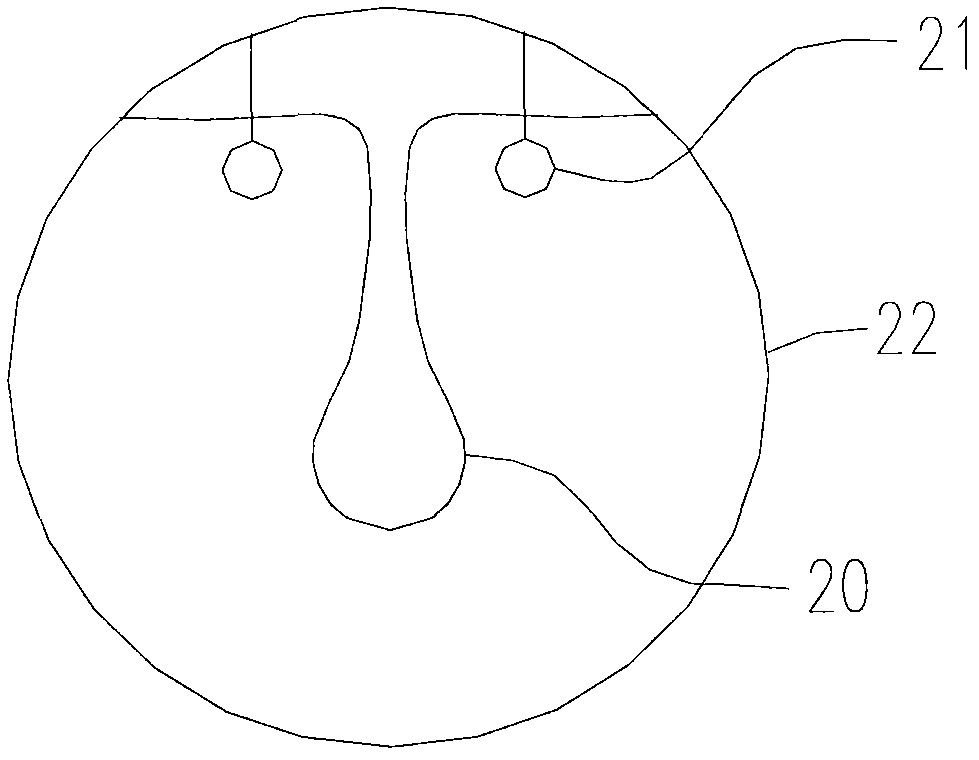

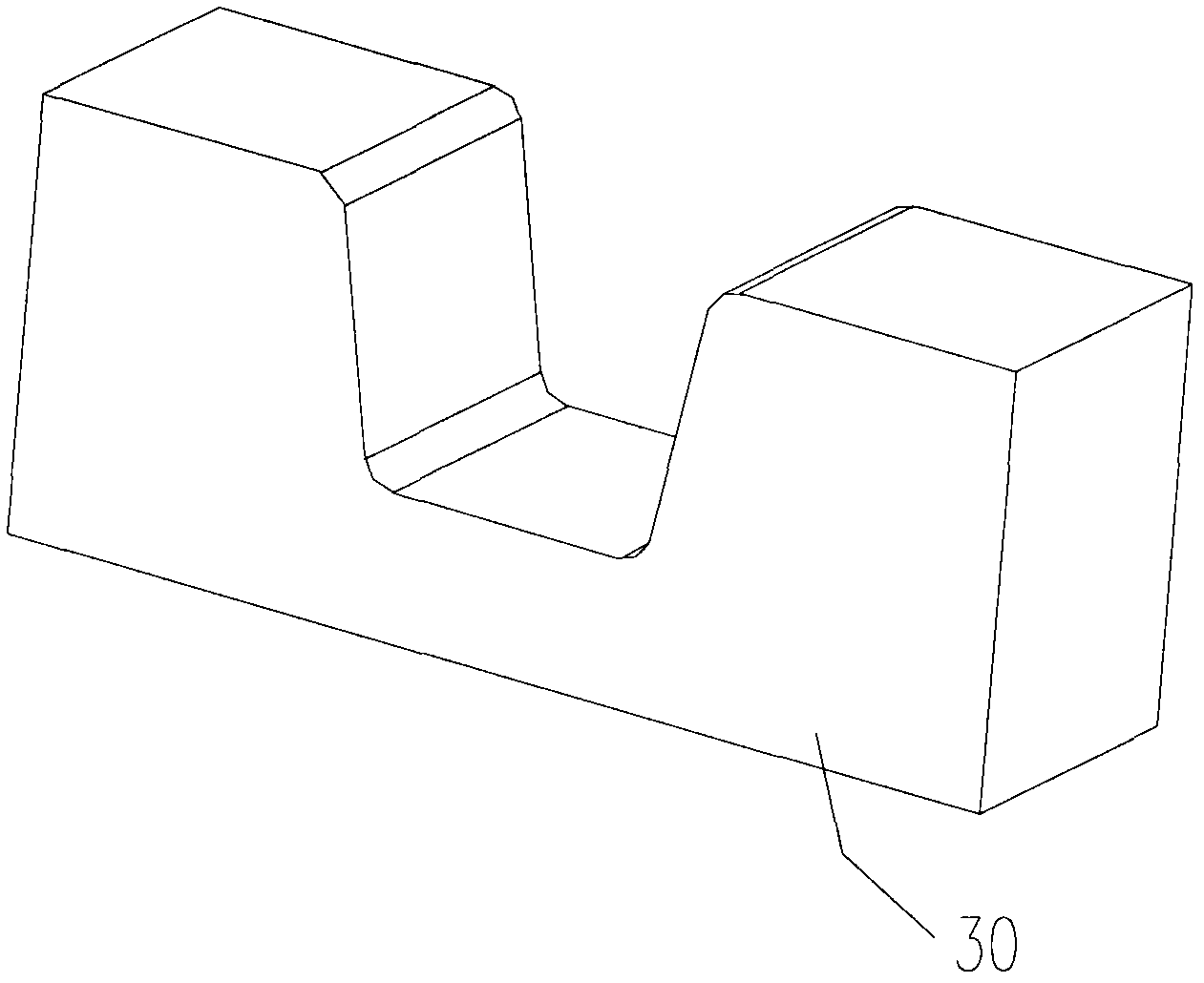

[0037] 1. A method for controlling the mold cooling rate in sections, comprising:

[0038] At least one cooling passage is provided in a mold, the at least one cooling passage includes a first segment and a second segment, wherein the first segment includes a first heat dissipation inner surface area, and the second segment includes a a second heat sink internal surface area; and

[0039] A heat dissipation component is used to non-uniformly adjust the first heat dissipation inner surface area and the second heat dissipation inner surface area.

[0040] 2. The method of embodiment 1, wherein the die is a hot stamping die.

[0041] 3. The method according to any one of the above embodiments, wherein the heat dissipation component is at least one of a fin and a copper foil structure.

[0042] 4. The method according to any one of the preceding embodiments, wherein the heat dissipation component is a replaceable component.

[0043] 5. The method according to any one of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com