Bolt supporting surface sharp milling cutter and processing process for processing a bolt supporting surface of a connecting rod cap by utilizing bolt supporting surface sharp milling cutter

A bolt support and processing technology, applied in milling cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of increased cutting resistance, waste, and high tool cost, and achieve the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

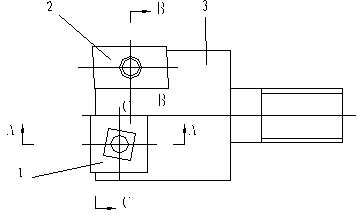

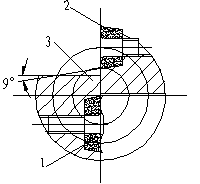

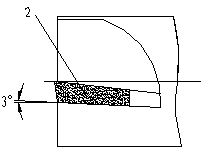

[0020] As shown in the figure, the powerful milling cutter of the present invention is composed of two different blades. The 12.7×12.7 square blade 1 and the 16.5×9.5 rhombic blade 2 are respectively arranged at 180°. 9.5 The 2 sides of the diamond-shaped blade are responsible for cutting with a diameter of φ31 on the outer edge. The functions of the two blades are different. According to the cutting principle and repeated tests, the square blade 1 undertakes the main powerful cutting task. The main cutting edge of the knife is set 0.4mm higher than the center of the knife, which is conducive to stable cutting; The 2 sides of the rhombic blade are responsible for the smoothing of the support surface and the R3 angle shape of the root of the bolt support surface. The main cutting edge of the knife is at the same height as the center of the knife, and the negative 3° makes the blade sharp when cutting the knife surface, reduces the vibration generated by cutting, and ensures the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com