Wetting type water spray windscreen wiper

A technology of wipers and wipers, which is applied in the field of wipers and wetted water spray wipers. It can solve the problems of spraying and lubrication in areas that cannot be wiped, water marks and linear residues, and easily damaged wipers. Effect of frictional resistance and blade protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

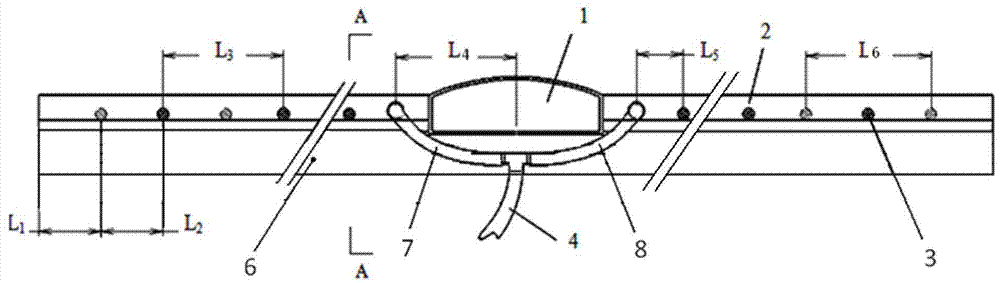

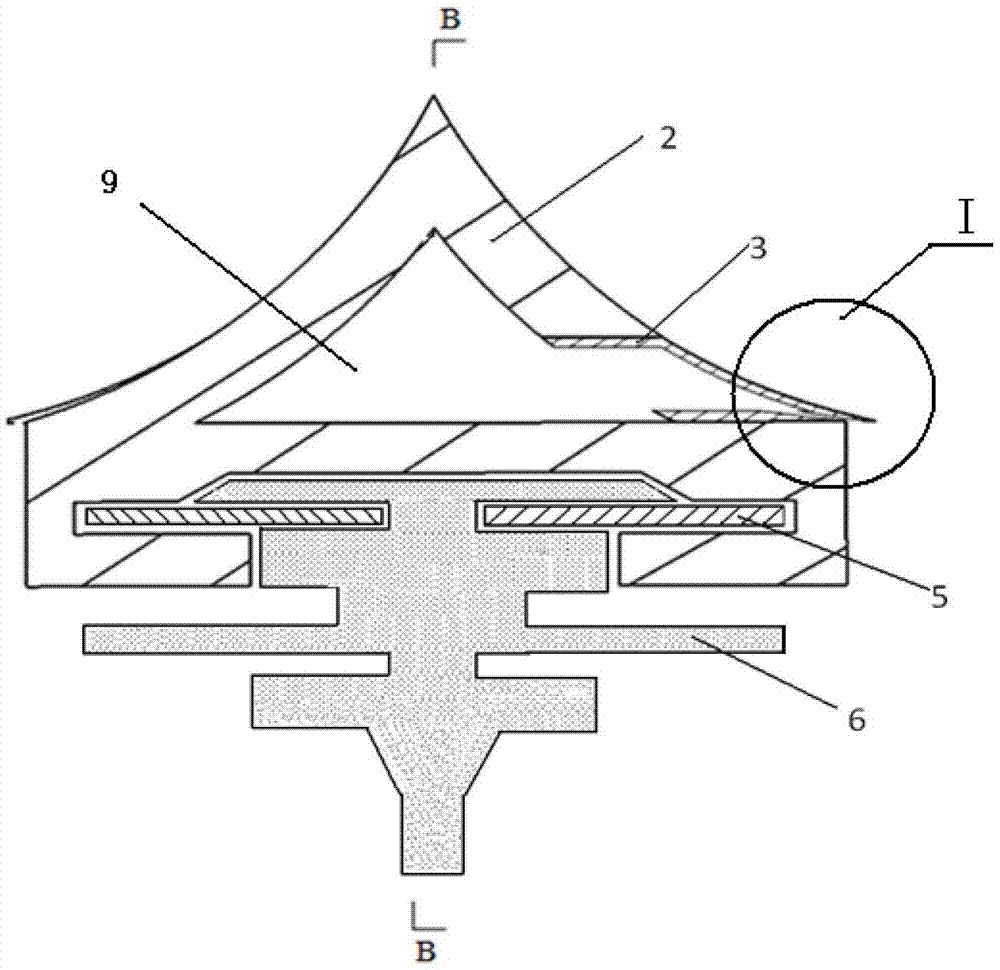

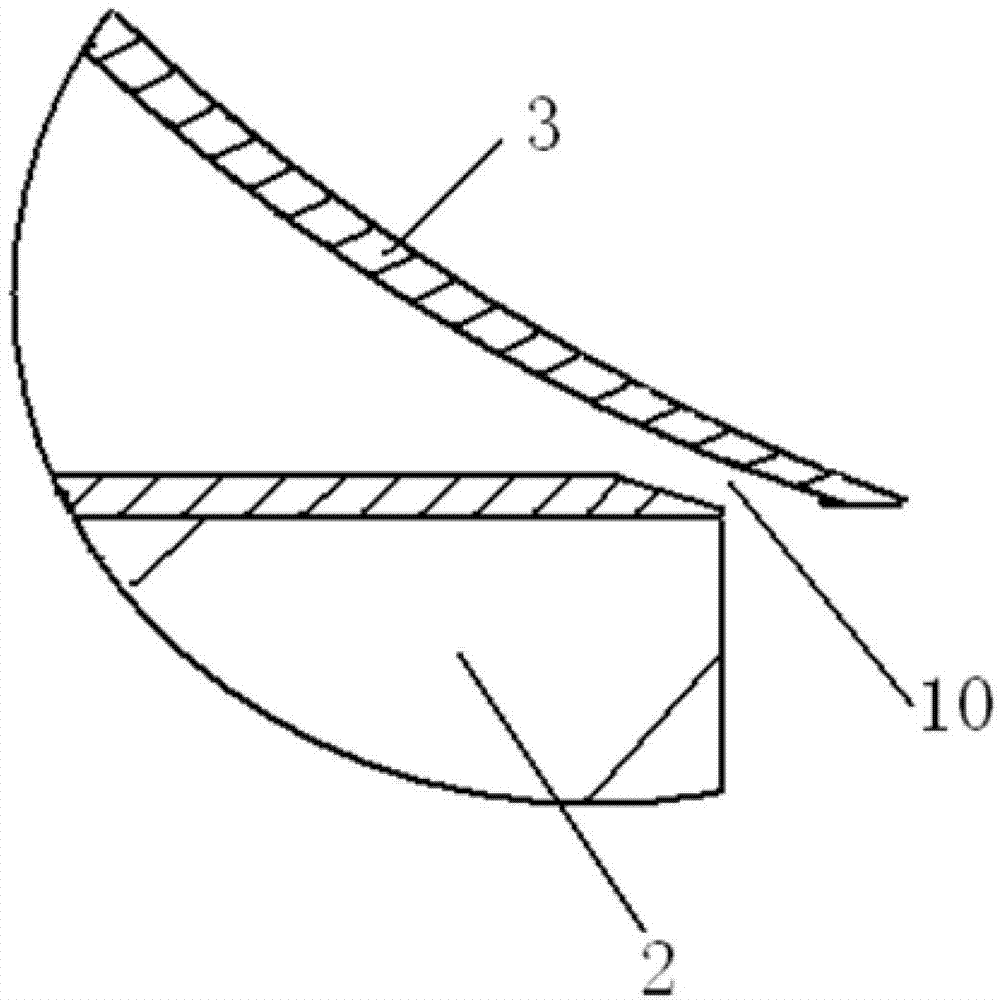

[0030] The length of the main driving wiper of FAW Land Cruiser is 20 inches, and the "herringbone" section of the guide vane is on the same side, and a clean water delivery pipe joint with a diameter of 3 mm is embedded at 40 mm on the left and right sides of the longitudinal axis, and the two sides are 10 mm away from the joint The sprinkler body with a diameter of 2mm is pre-embedded, and the sprinkler body is embedded every 50mm. The number of sprinkler bodies on the same side of the deflector pre-embedded clean water pipe joint is 8; Stagger 25mm on the side and pre-embed nozzles with a diameter of 2mm, the distance between the nozzles on the same side is 50mm, the number of nozzles on the opposite side of the clean water pipe joint is embedded in the deflector, and there are 16 pre-embedded on the deflector of the main driver's wiper Nozzle body. The length of the copilot wiper is 18 inches, the "herringbone" section of the deflector is on the same side, and a clean wate...

Embodiment 2

[0033] Jetta driver and co-pilot wipers are both 16 inches in length, and the "herringbone" section of the guide vane is on the same side, on the left and right sides of the longitudinal axis, and a clean water delivery pipe joint with a diameter of 3 mm is embedded at 40 mm, and the distance between the joints on both sides is Embed nozzle bodies with a diameter of 2mm at each 10mm, and pre-embed nozzle bodies every 50mm, and the number of nozzle bodies on the same side of the deflector pre-embedded clean water pipe joint is 6; the other side of the "herringbone" cross section of the deflector , stagger 25mm from the opposite side and embed nozzle bodies with a diameter of 2mm, the distance between the nozzle bodies on the same side is 50mm, the number of nozzle bodies on the opposite side of the deflector pre-embedded clean water pipe joint is 6, and the main and passenger wipers are on the deflector A total of 12 nozzle bodies are pre-embedded.

[0034]The wetting type wipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com