ABS (Acrylonitrile-Butadiene-Styrene) highlight packing master batch and preparation method thereof

A technology of filling masterbatch and high gloss, applied in the field of masterbatch, can solve the problems of poor compatibility, influence, poor material processing performance, etc., and achieve the effect of improving toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

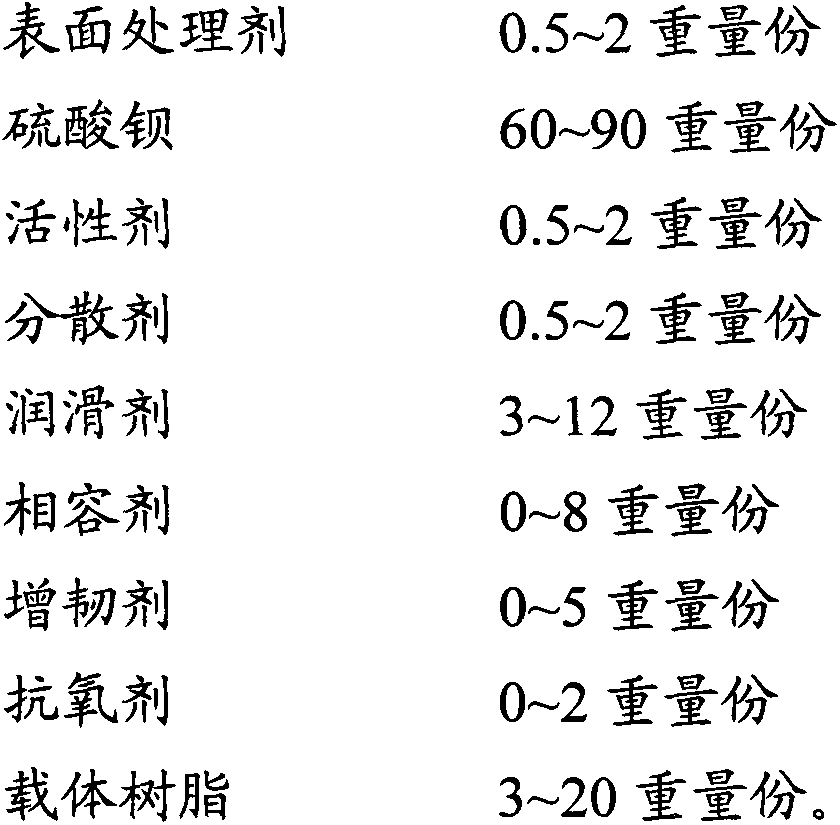

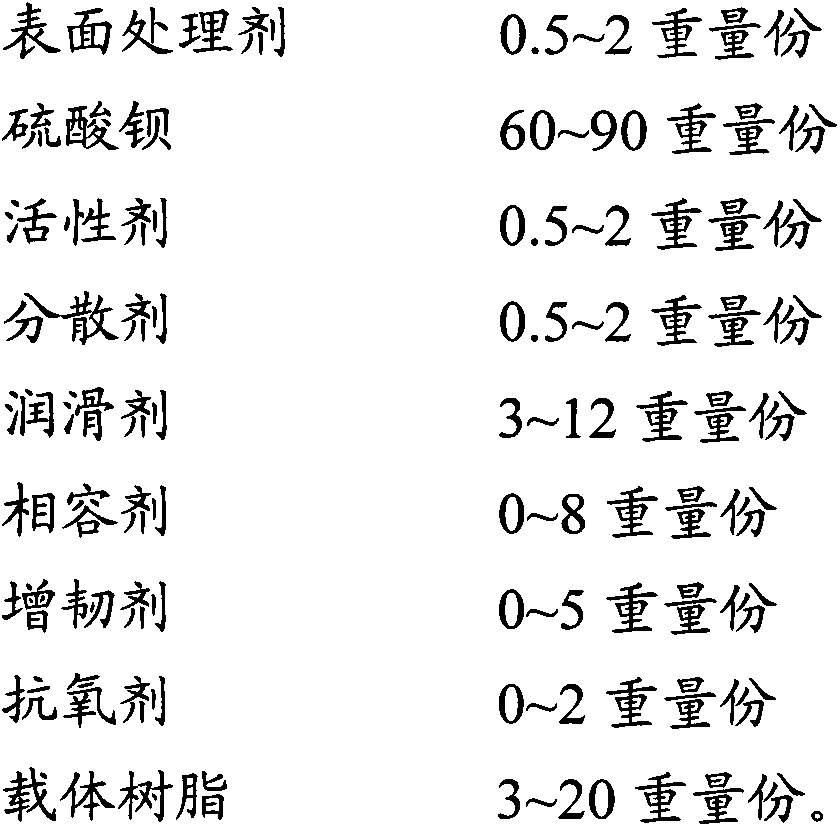

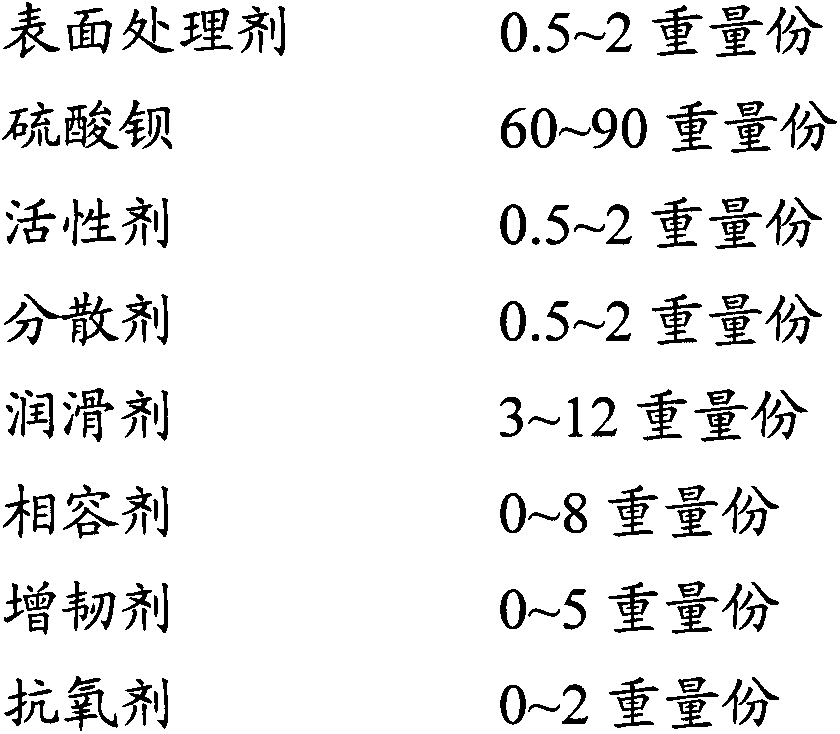

[0034]Correspondingly, the present invention also provides a preparation method of ABS high-gloss filling masterbatch, using the above-mentioned raw materials, combining a twin-screw extruder, an open mill and a twin-screw extruder, a banbury mixer and a twin-screw extruder Combined, continuous internal mixer for processing. Taking the twin-screw extruder as an example, the ABS high-gloss filler masterbatch is prepared according to the following method, including the following steps: stirring 60-90 parts by weight of barium sulfate at a high speed at 50-70°C, adding 0.5-2 parts by weight Surface treatment agent, 0.5-2 parts by weight of active agent and 0.5-2 parts by weight of dispersant, after high-speed stirring, add 3-12 parts by weight of lubricant, 0-8 parts by weight of compatibilizer, 0-5 parts by weight of toughening agent, 0-2 parts by weight of antioxidant and 3-20 parts by weight of carrier resin are stirred at a low speed to obtain a mixed material; the mixed mate...

Embodiment 1

[0050] (1) According to the weight ratio of ingredients

[0051]

[0052]

[0053] (2) Activation: the weighed filler BaSO 4 Place in a high-speed mixer and stir at a high speed for 5 minutes at a temperature of 50-70°C, then add surface treatment agents, active agents, and dispersants and stir at high speed for 3 minutes, then add other materials and stir at low speed for 3 minutes.

[0054] (3) Mixing: put the above-mentioned stirred materials into a twin-screw extruder for uniform plasticization, and the plasticization temperature is divided into 12 heating zones in sequence from the entrance to the exit, respectively:

[0055]

[0056] (4) Die face cutting: the material is uniformly plasticized by the twin-screw extruder and extruded from the porous die plate of the extruder head into strips, and is cut off while hot by a high-speed rotary cutter placed on the mold section. grainy.

[0057] (5) First-level air cooling: the material cut into granules by the die s...

Embodiment 2

[0065] Ingredients by weight ratio

[0066]

[0067] (2) Activation: the weighed filler BaSO 4 Place in a high-speed mixer and stir at a high speed for 5 minutes at a temperature of 50-70°C, then add surface treatment agents, active agents, and dispersants and stir at high speed for 3 minutes, then add other materials and stir at low speed for 3 minutes.

[0068] (3) Mixing: Put the above-mentioned stirred materials into a twin-screw extruder for uniform plasticization, and the plasticization temperature is divided into 12 heating zones in sequence from the inlet to the outlet, respectively

[0069]

[0070] (4) Die face cutting: the material is uniformly plasticized by the twin-screw extruder and extruded from the porous die plate of the extruder head into strips, and is cut off while hot by a high-speed rotary cutter placed on the mold section. grainy.

[0071] (5) First-level air cooling: the material cut into granules by the die surface falls into the air supply pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com