High-pressure gear pump floating side plate with pressing plate

A floating side plate, gear pump technology, applied in the direction of rotary piston type/swing piston type pump components, pump elements, machines/engines, etc. Hydraulic gear pump mechanical efficiency and other issues, to achieve the effect of improving sealing effect, enhancing sealing effect and safety performance, improving reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

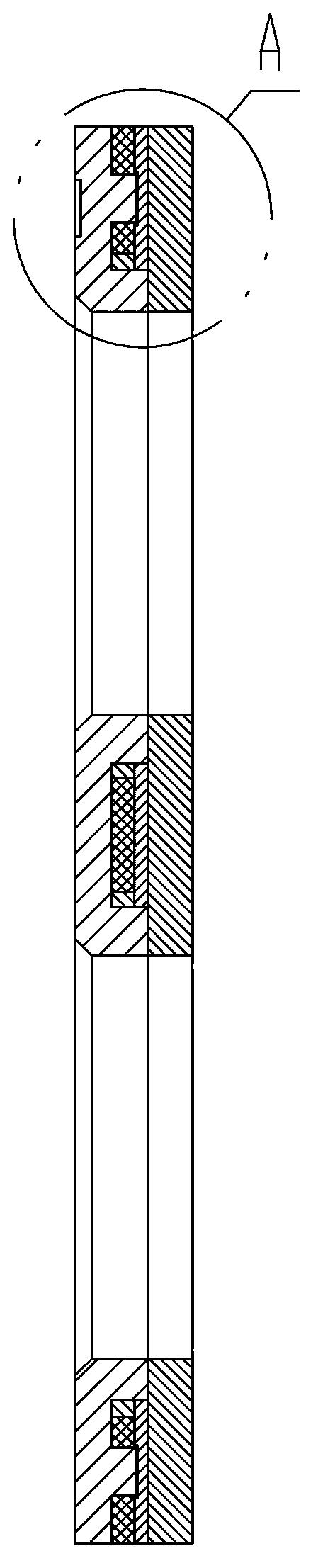

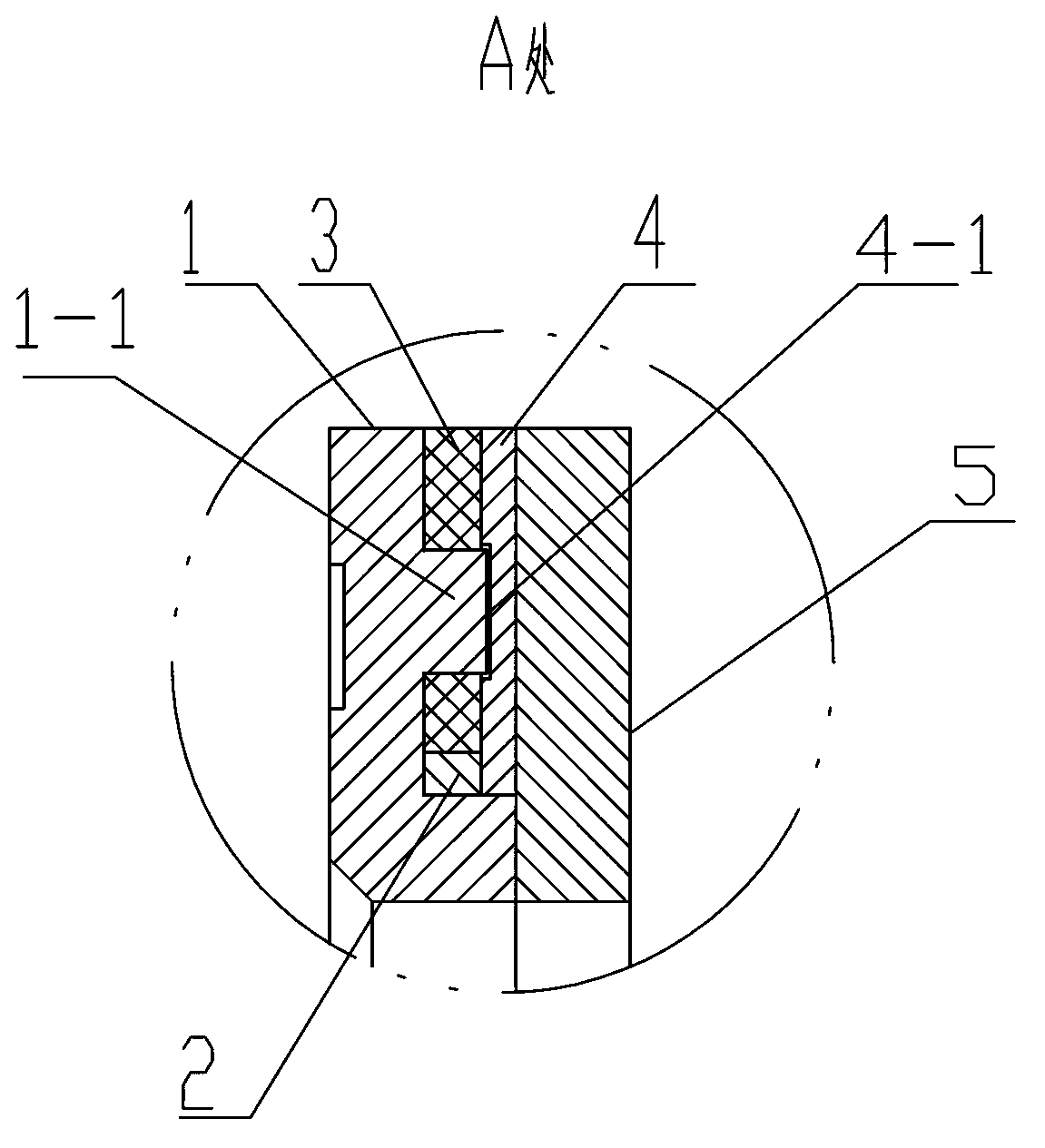

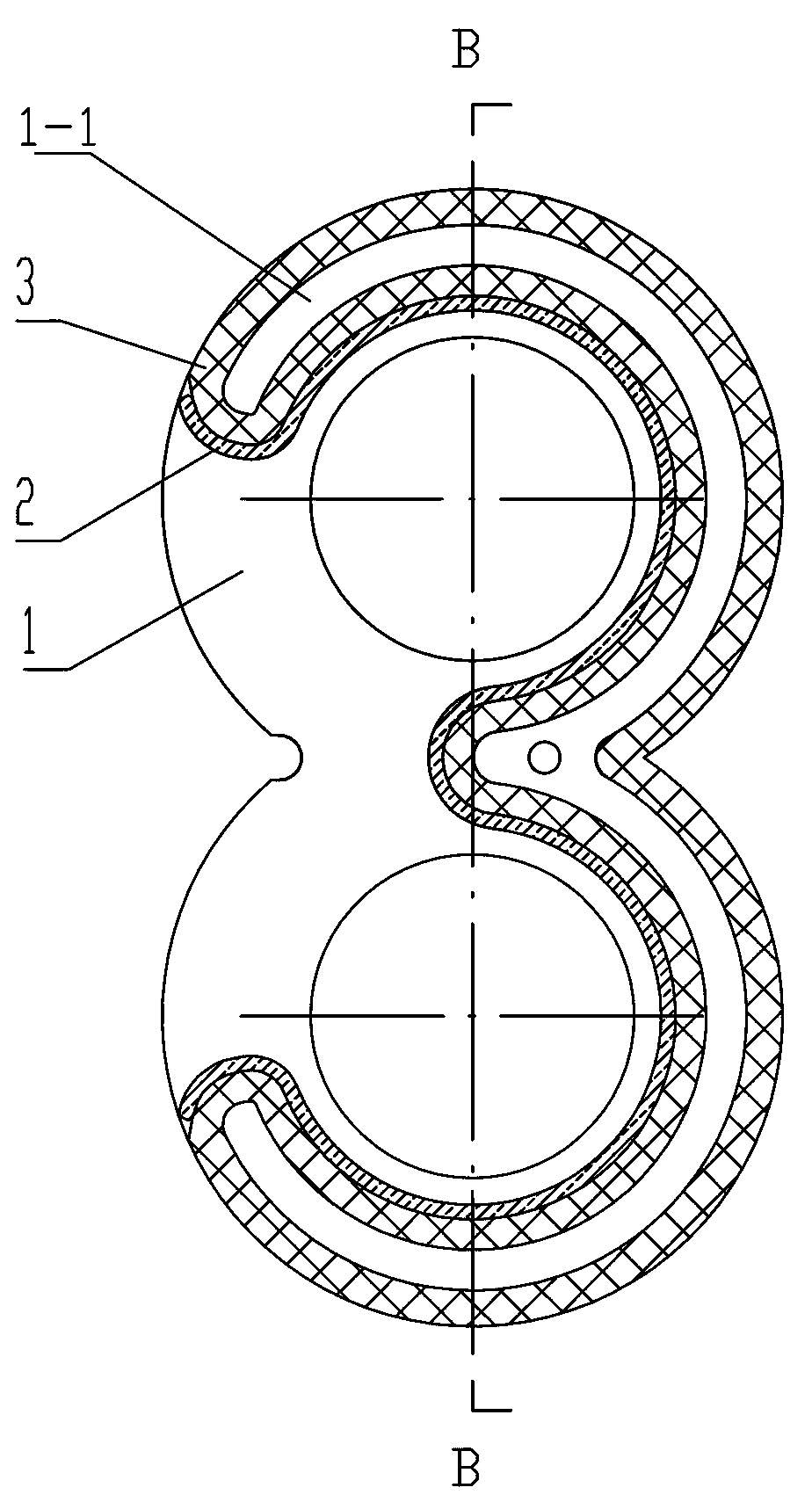

[0020] As shown in the drawings, a floating side plate of a high-pressure gear pump with a pressure plate includes a floating side plate 1 that matches the gears in the gear pump, and a “W” is made on the side of the floating side plate 1 close to the end face of the gear. Shaped balance tank a, unloading tank b communicating with balance tank a, the other side of the floating side plate 1 is made with a "W" shaped seal groove d, and there is a "W" in the "W" shaped seal groove d Shaped reinforcing rib 1-1, a through hole c is made between the "W" shaped sealing groove d and the unloading groove b, and a "W" shaped sealing ring 3 is housed in the described "W" shaped sealing groove d, The "W"-shaped sealing ring 3 is integrally set on the "W"-shaped reinforcing rib 1-1, and the thickness of the "W"-shaped reinforcing rib 1-1 is smaller than the depth of the "W"-shaped sealing groove d, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com