Intelligent lighting control system

A control system and intelligent lighting technology, applied in energy-saving control technology, light source, electric light source, etc., can solve problems such as crash, reduce the working life of electrical equipment, burn out electronic equipment, etc., achieve good surge protection function, avoid damage control circuit, to ensure the effect of safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

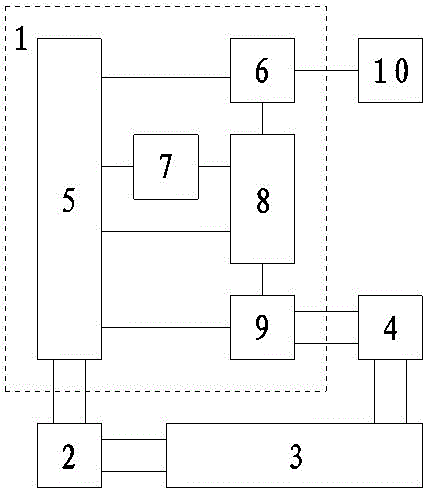

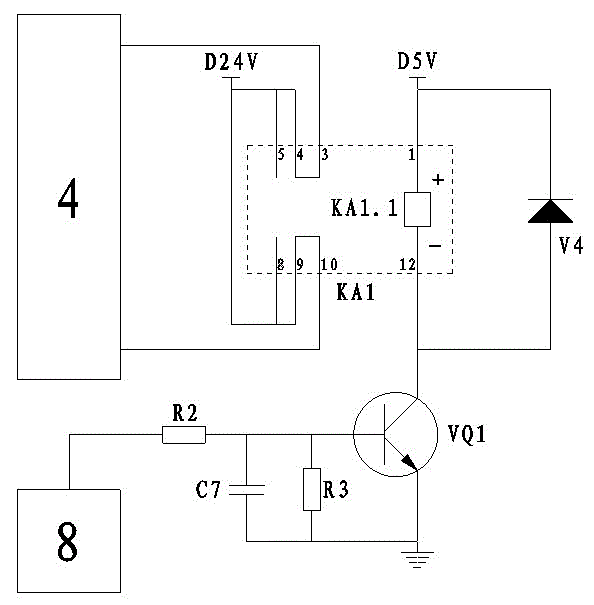

[0035] Such as Figure 1 to Figure 4 所示,本发明智能灯光控制系统,包括:主机控制单元1、控制箱电源2、市电电源3和灯光模块4;所述主机控制单元1包括:电源保护模块5、数据通讯模块6、时钟控制模块7、微控制器8和继电器灯控模块9,所述电源保护模块5分别与数据通讯模块6、时钟控制模块7、微控制器8和继电器灯控模块9相连;

[0036] 所述微控制器8的信号输入端与时钟控制模块7相连,微控制器8的数据通讯端与数据通讯模块6相连,微控制器8的信号输出端与继电器灯控模块9相连;

[0037] 所述市电电源3的电源输出端分别与控制箱电源2和灯光模块4相连;

[0038] 所述控制箱电源2的电源输出端与电源保护模块5相连,继电器灯控模块9的信号输出端与灯光模块4的输入端相连。

[0039] 本发明中微控制器8使用型号为ATMEGA64A的AVR单片机芯片,控制简单,工作稳定,不会产生累计误差,可以保证与周围模块高速稳定的进行数据交换,并且其使用的信号输出端具有使用灵活、驱动电流大等特点,非常适合驱动小型继电器。

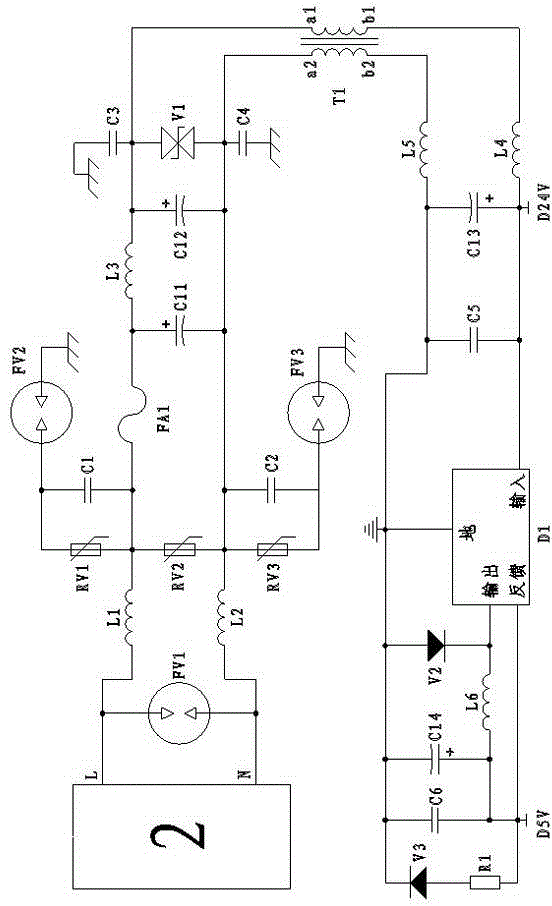

[0040] 所述电源保护模块5的电路结构为:控制箱电源2的火线端并接气体放电管FV1的一端后与滤波磁珠L1的一端相连,控制箱电源2的零线端并接气体放电管FV1的另一端后与滤波磁珠L2的一端相连;

[0041] 所述滤波磁珠L1的另一端依次并接压敏电阻RV1的一端、电容C1的一端后与保险丝FA1的一端相连,所述压敏电阻RV1的另一端并接电容C1的另一端后与气体放电管FV2的一端相连,所述气体放电管FV2的另一端接地;

[0042]The other end of the fuse FA1 is connected in parallel with the positive pole of the polar capacitor C11 and then connected with one end of the inductor L3, and the other end of the inductor L3 is sequentially connected in parallel with the positive pole of the polar capacitor C12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com