Method used for medium and low temperature mold dismantling of large-scale extra-thick plate blank

An ultra-thick slab, large-scale technology, applied in the field of medium and low temperature boxing of large-scale ultra-thick slabs, can solve the problems of shrinkage porosity, cracks, macro-segregation, etc. The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

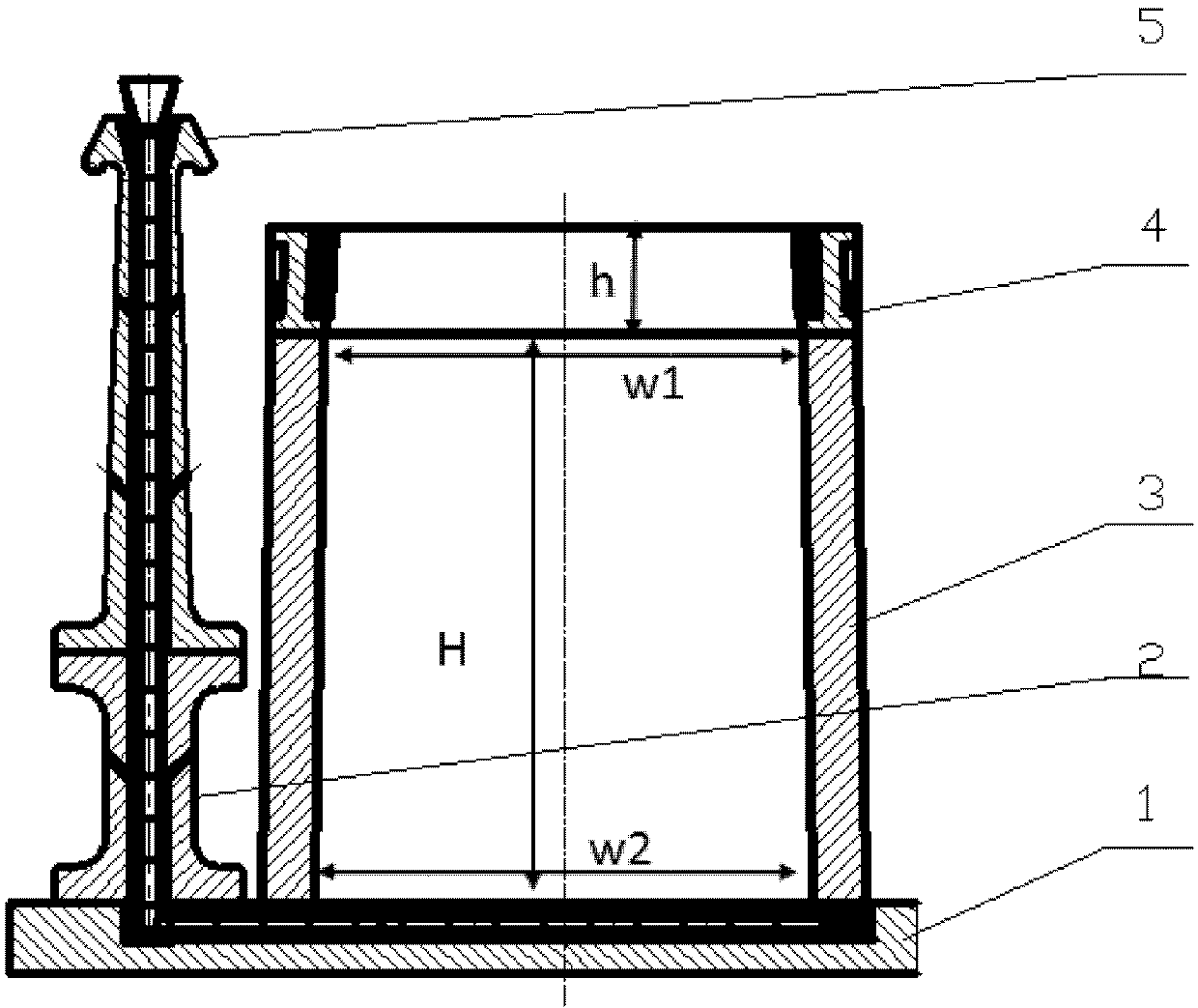

[0027] In this embodiment, a wide and thick slab with an overall size of 1000×2700×3300mm and a unit weight of 60t is produced by adopting the process described in the present invention. The specific process is as follows:

[0028] The material of the wide and thick slab is EH36. When the molten steel is poured into the cavity of the metal mold for 1 hour, the outer surface of the metal mold of the wide and thick slab is forced to be cooled by intermittent blowing. The surface temperature is maintained between 80 and 120°C. The wide and thick slab is completely solidified after 4 hours, and the blowing cooling of the metal mold is stopped. The wide and thick slab continues to cool down in the mold. When the temperature of the outer surface of the slab drops to 600°C, the box is opened, and the wide and thick slab is released from the metal mold. The billet is cooled slowly, and the cooling rate is controlled at 40-80°C / h.

[0029] The wide and thick slab produced in this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com