Ultraviolet laser processing device

A processing device, ultraviolet laser technology, applied in the direction of laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that ordinary laser positioning cannot meet, difficult to meet product marking and cutting accuracy requirements, etc., to meet processing accuracy, The effect of precise marking and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

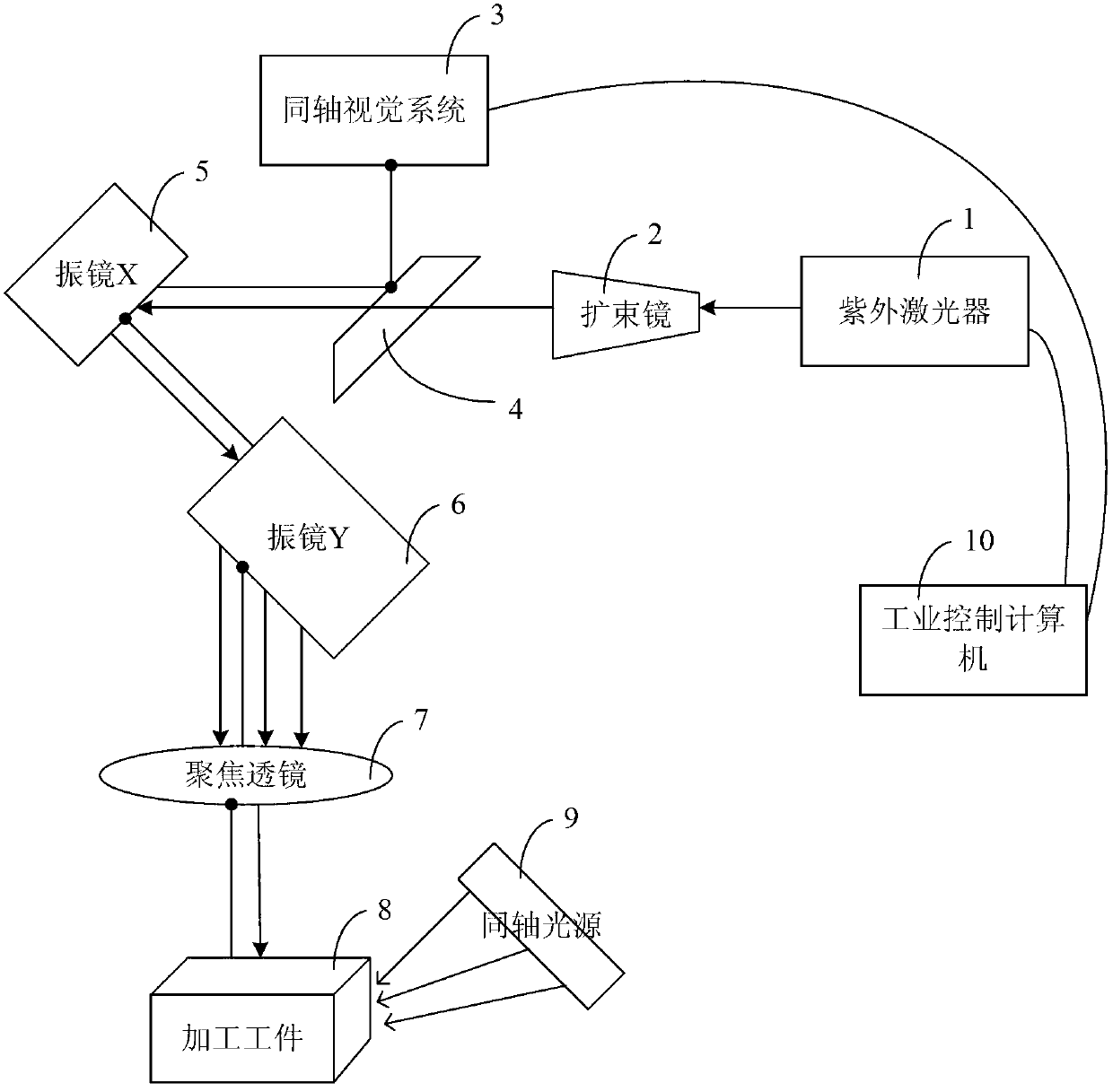

[0012] Such as figure 1 , the ultraviolet laser processing device of the present invention comprises ultraviolet laser device 1, vibrating mirror system, focusing lens 7, is also provided with splitter 4 on the optical path between ultraviolet laser device 1 and vibrating mirror X5, is also provided with splitter sheet 4 top There is a coaxial vision system 3, and the coaxial light source 9 in the coaxial vision system 3 is set on one side of the workpiece 8;

[0013] The ultraviolet laser beam emitted by the ultraviolet laser 1 is horizontally incident on the beam splitter 4, passes through the transmission of the beam splitter 4, then undergoes total reflection of the vibrating mirror system, and finally refracts through the focusing lens 7 to converge the ultraviolet laser beam to the workpiece 8. Realize accurate marking and cutting o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com