Manufacturing method of metal and plastic combination body and combination body

A composite and plastic technology, applied in the composite field, can solve the problems of limited application, weak bonding force between aluminum alloy and plastic parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

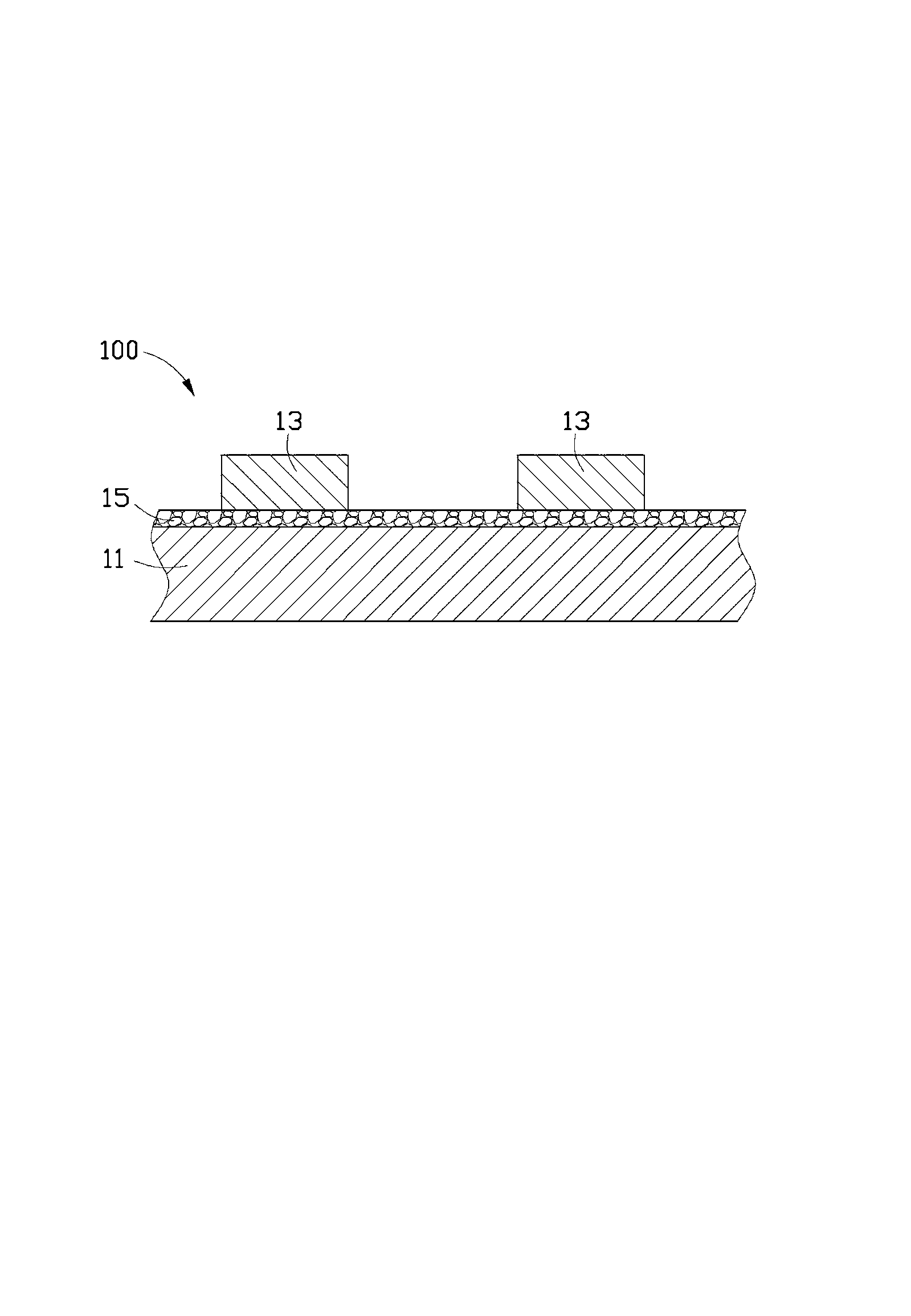

[0016] see figure 1 , the preparation method of the metal-plastic composite 100 in a preferred embodiment of the present invention includes the following steps:

[0017] (1) Provide aluminum or aluminum alloy substrate 11.

[0018] (2) Perform conventional degreasing and degreasing treatment on the aluminum or aluminum alloy substrate 11 . Alcohol, acetone, and water are used to clean the aluminum or aluminum alloy substrate 11 in order to remove surface dirt.

[0019] (3) Soaking and corroding the aluminum or aluminum alloy substrate 11 with a cleaning solution. The cleaning solution contains 18% nitric acid (HNO 3 ) and 10% hydrofluoric acid (HF). The immersion corrosion can remove the oxide film layer formed on the surface of the aluminum or aluminum alloy substrate 11 .

[0020] (4) Electrochemically corroding the aluminum or aluminum alloy substrate 11 after immersion corrosion, so that the surface of the aluminum or aluminum alloy substrate 11 is corroded to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com