Band-aid cold-seal package free of natural latex and manufacturing method of band-aid cold-seal package

A natural latex, Band-Aid technology, used in packaging, wrapping paper, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of band-aid cold-seal package and preparation method thereof not containing natural latex

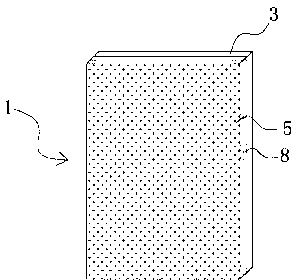

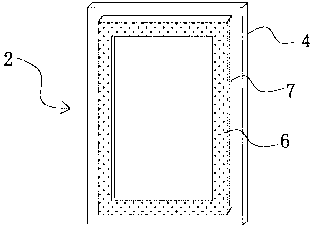

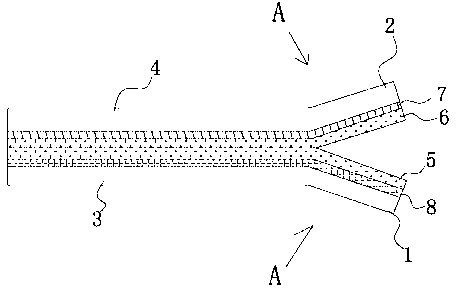

[0032] see Figure 1 to Figure 4 As shown, the Band-Aid cold-seal package is composed of a first packaging sheet 1 and a second packaging sheet 2 that cover the Band-Aid 9, and the first packaging sheet 1 is composed of a first base material 3 and coated on the first base material. 3 on the inner side of the first base material coating composition, the second packaging sheet 2 is composed of the second base material 4 and the second base material coating coating on the inner side of the second base material 4 around the edge; The first substrate coating is used as the first contact adhesive layer 5 and bonded on the inner side of the first substrate 3; the second substrate coating consists of a release coating 7 and a second contact adhesive layer 6, wherein the release coating 7 is coated on the inner side of the second substrate 4 at the peripheral edge, a...

Embodiment 2

[0045] Embodiment 2: A kind of band-aid cold-seal package and preparation method thereof not containing natural latex

[0046] see Figure 5 As shown, the Band-Aid cold-seal package is composed of a first packaging sheet 1 and a second packaging sheet 2 that cover the Band-Aid 9, and the first packaging sheet 1 is composed of a first base material 3 and coated on the first base material. 3 on the inner side of the first base material coating composition, the second packaging sheet 2 is composed of the second base material 4 and the second base material coating coating on the inner side of the second base material 4 around the edge; The first substrate coating is used as the first contact adhesive layer 5 and bonded on the inner side of the first substrate 3; the second substrate coating consists of a release coating 7 and a second contact adhesive layer 6, wherein the release coating 7 is coated on the inner side of the second substrate 4 at the peripheral edge, and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com