Sealant composition for display element with improved liquid crystal contamination problem and sealant formed by curing the same

A liquid crystal display element and sealant technology, which is applied in the direction of adhesive additives, modified epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problem of contaminating liquid crystals, producing streaks, aggravating streaks, afterimages, etc. problems, achieve the effect of improving thixotropy, maintaining strength and improving adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

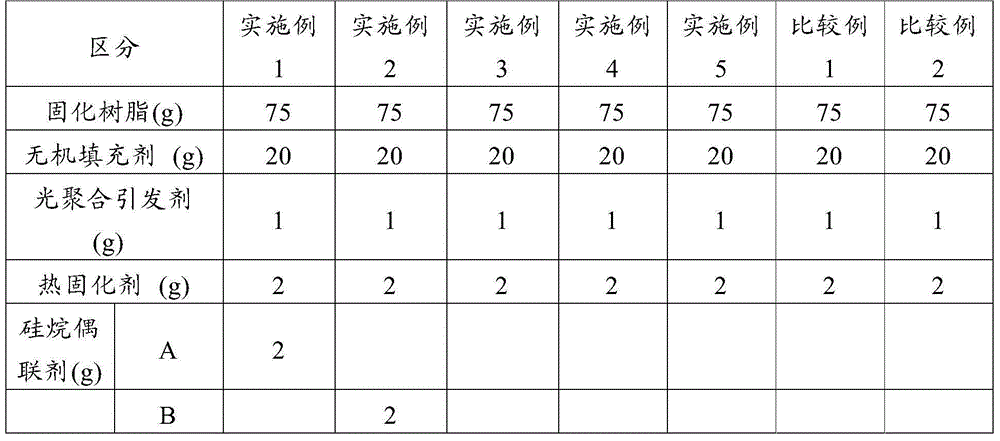

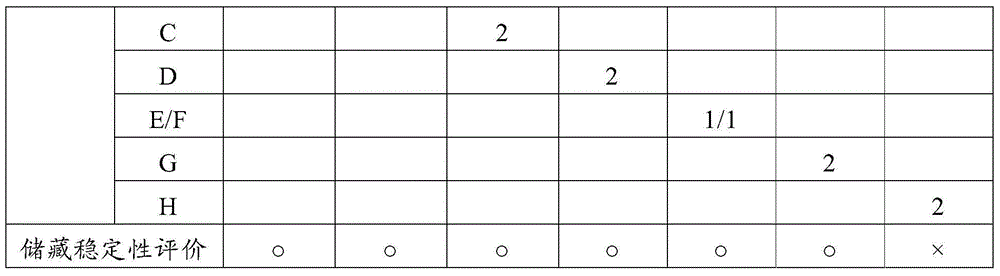

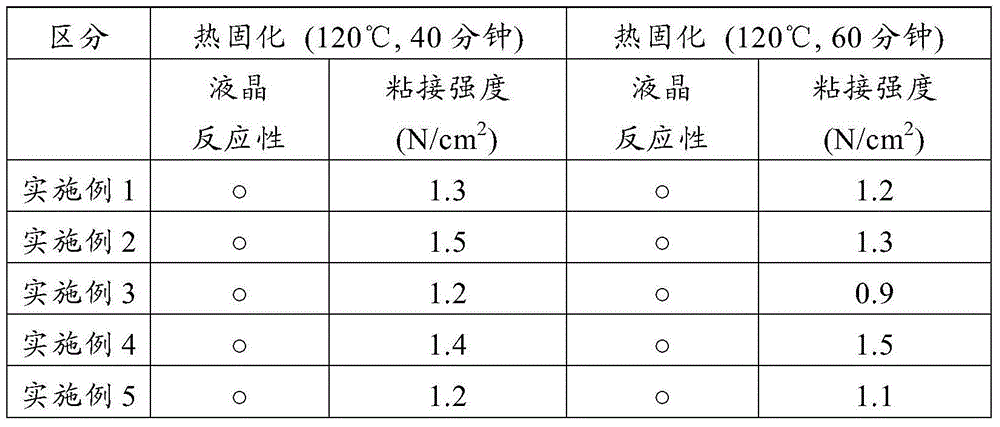

Embodiment 1

[0037] The proportion includes 75g of (meth)acrylic epoxy resin of 2g of thermal curing agent, 3-(triethoxysilyl)propyl acrylate (3-(Triethoxysilyl)propyl acrylate) (A) 2g, photopolymerization initiator 1g of agent and 20g of inorganic filler were preliminarily mixed, then fully ground with a 3-roll mill, and vacuum defoamed with a rotation and revolution defoamer to obtain a resin composition.

Embodiment 2

[0039] The proportion includes 75g of (meth)acrylic epoxy resin of 2g of thermal curing agent, 3-(triethoxysilyl)propyl methacrylate (3-(Triethoxysilyl)propyl Methacrylate) (B) 2g, light 1 g of polymerization initiator and 20 g of inorganic filler were preliminarily mixed, then fully ground by a 3-roll mill, and vacuum defoamed by a rotation and revolution defoamer to obtain a resin composition.

Embodiment 3

[0041] The proportion includes 75g of (meth)acrylic epoxy resin of 2g of thermal curing agent, 3-(triethoxysilyl)propyl methacrylate (3-(Triethoxysilyl)propyl Methacrylate) (C) 2g, light 1 g of polymerization initiator and 20 g of inorganic filler were preliminarily mixed, then fully ground by a 3-roll mill, and vacuum defoamed by a rotation and revolution defoamer to obtain a resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com