Downhole spiral flow shear vibration generator device

A technology of swirling flow generator and shear vibration, which is applied to vibration generating devices, wellbore/well components, earthwork drilling and production, etc., which can solve problems such as excessive rotational torque, too fast rotational speed, and increased operational risks. Achieve the effects of increasing interface cementing strength, improving displacement efficiency, and improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, invention will be further described:

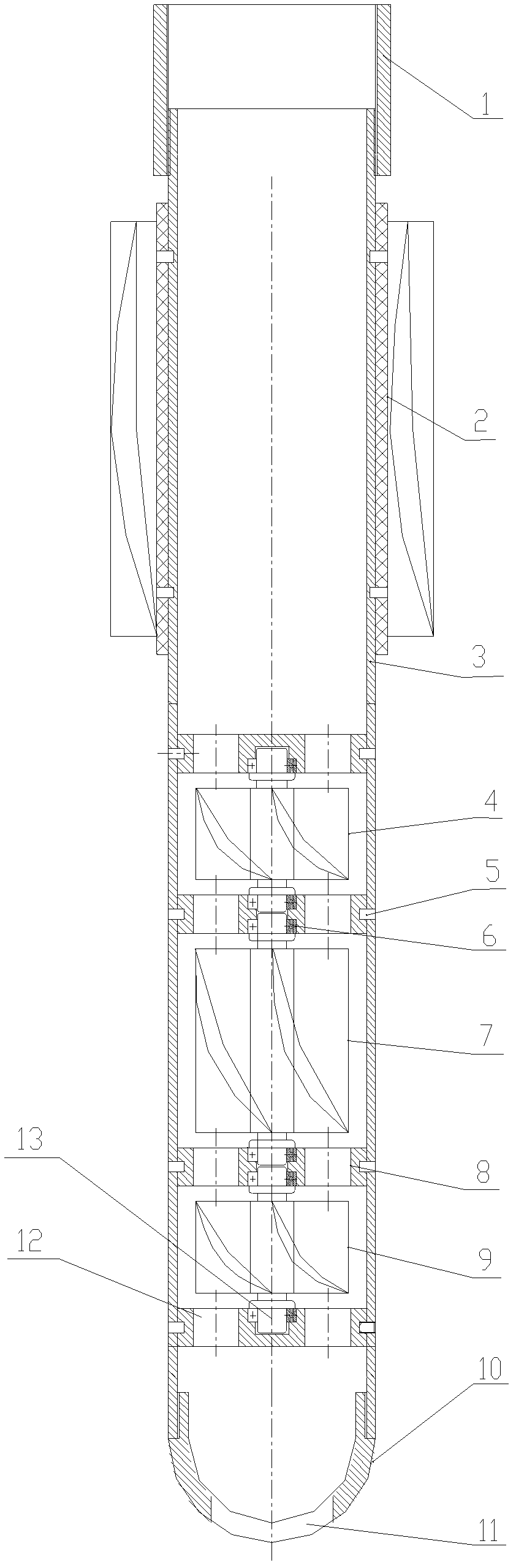

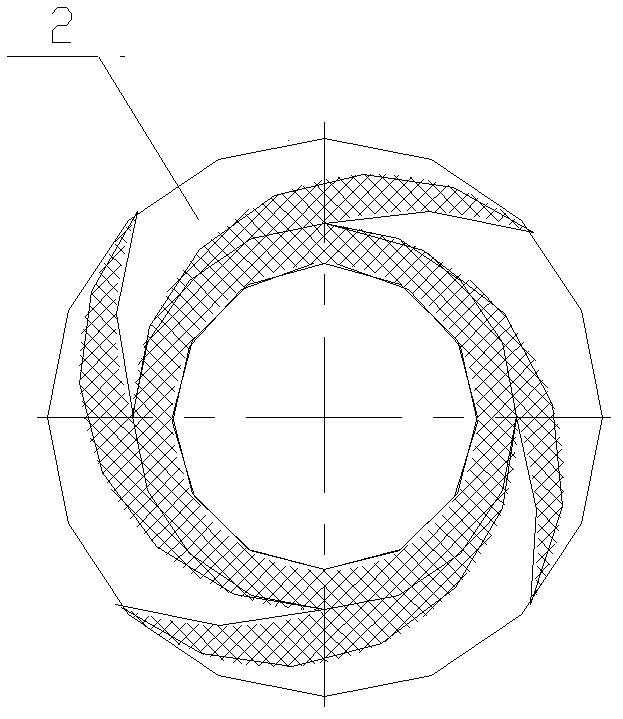

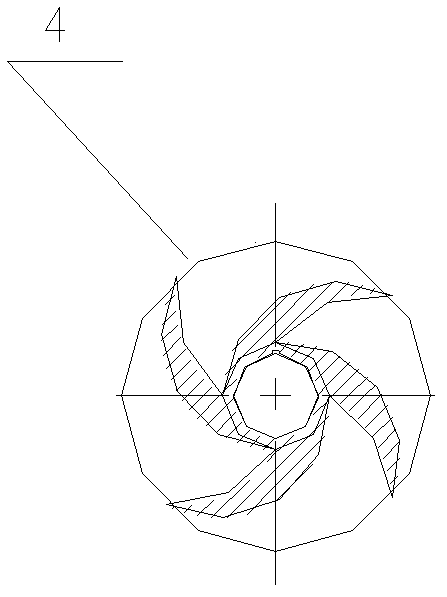

[0012] Depend on Figure 1 to Figure 3 As shown, the downhole swirl shear vibration generator device includes a coupling 1, an outer cylinder 3 and a deflector seat 10 which are screwed in sequence, wherein the upper outer wall of the outer cylinder 3 is fixed by a locking screw 5. Generator 2, the lower part of the inner hole of the outer cylinder 3 is provided with a shear rotor 4, a vibration rotor 7 and a swirl rotor 9 from top to bottom; the swirl generator 2 has evenly distributed spiral blades and is made of plastic material, such as figure 2 As shown, the shearing rotor 4, the vibrating rotor 7 and the swirl rotor 9 are metal structures with helical blades evenly distributed thereon, as image 3 As shown, in this embodiment, the number of helical blades is four. The shearing rotor 4, the vibrating rotor 7 and the swirling rotor 9 are fixed on the shaft 13 through the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com