Method and device for adjusting housing part modality of combustion engine in changeable and dynamic mode

A technology of dynamic adjustment, internal combustion engine, applied in vibration suppression adjustment, non-rotation vibration suppression and other directions, can solve the problem of not being able to automatically adjust the modal mode shape and frequency of shell parts, and achieve a simple and compact structure, eliminate radiation noise, and improve performance. The effect of the low frequency noise cancelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

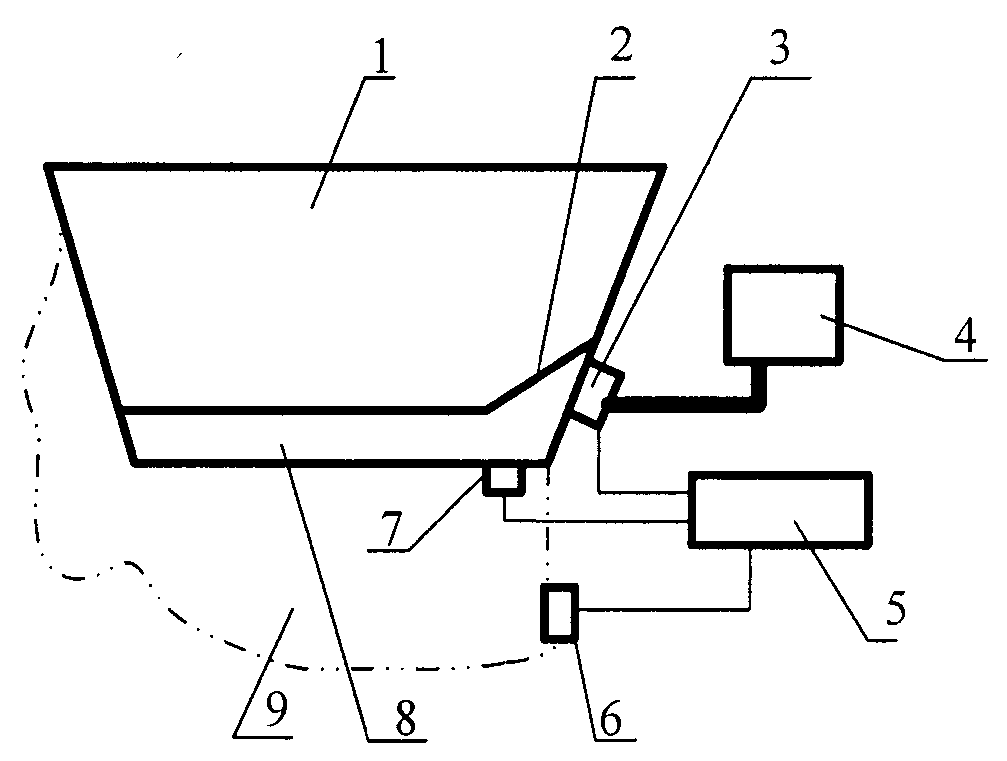

[0022] Such as figure 1 Shown: a mode-variable adjustment device for casing parts of an internal combustion engine, including a casing part 1, an isolation membrane 2, an electric / magneto-rheological fluid two-way flow control valve 3, an electric / magneto-rheological fluid container 4, PLC controller 5, internal combustion engine speed sensor 6, electric field / magnetic field control mechanism 7 and rheological fluid chamber 8. The casing part 1 is a shell part or part of the internal combustion engine 9, which can be an oil pan, an exhaust manifold cover, an exhaust two-manifold cover, an intake muffler, and an exhaust muffler. The rheological fluid chamber 8 is formed by setting the isolation membrane 2 in the casing parts 1, and the isolation membrane 2 and part of the casing parts 1 form a relatively closed space, which can pass through the electric / magneto-rheological fluid chamber 8. The liquid two-way flow control valve injects electro / magneto-rheological fluid, and the...

Embodiment 2

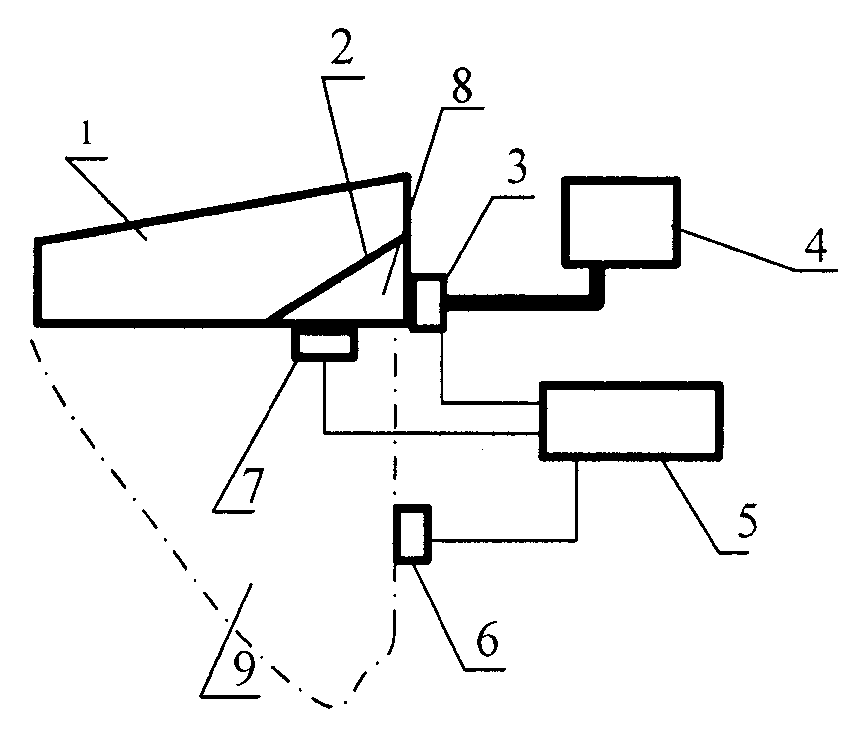

[0024] Such as figure 2 As shown: it is based on the structure of Embodiment 1, the electric / magneto-rheological fluid two-way flow control valve 3, the electric / magneto-rheological fluid container 4 and the applied electric field / magnetic field control mechanism 7 adopt the magnetorheological fluid two-way A flow control valve, a magnetorheological fluid container and a magnetic field control mechanism, the magnetorheological fluid container is filled with magnetorheological fluid. The casing part 1 is an oil pan, which is a casing part that is easy to radiate noise from the internal combustion engine. Its working method is: when the rheological fluid enters the mold cavity 8, the PLC controller 5 issues instructions to the magnetic field control mechanism 7, and the rheological fluid in the mold cavity 8 becomes solid instantaneously by applying a magnetic field.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com