Radius error compensation control method and device for CNC machine tool contour machining

A CNC machine tool and contour processing technology, which is applied in digital control, electrical program control, etc., can solve problems such as insufficient contour processing accuracy of CNC machine tools, and achieve the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

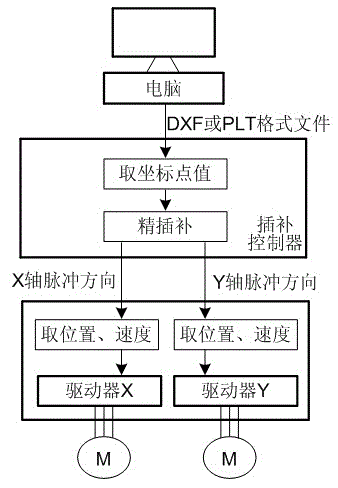

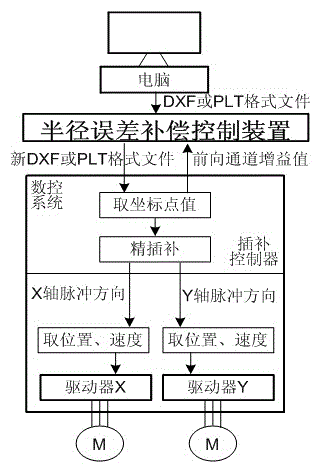

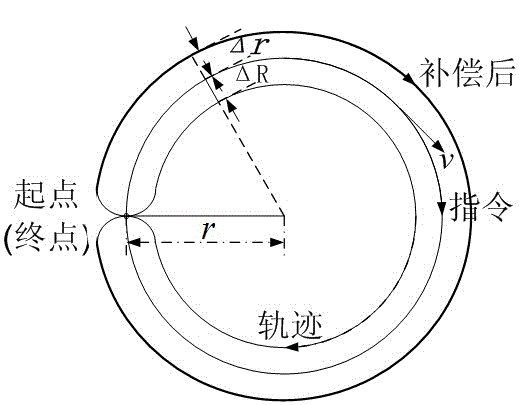

[0042] Such as figure 2 As shown, in this embodiment, the device for improving the contour machining accuracy of the CNC machine tool is the position tracking error compensation controller. The core of position tracking error compensation controller is microprocessor. This embodiment includes the following control steps:

[0043] (1) Insert (series) the position tracking error compensation controller into the data transmission channel between the computer and the numerical control system. figure 2 In the schematic diagram of motion control system components, the CNC system consists of an interpolation controller and servo drives for each axis.

[0044] (2) The microprocessor in the position tracking error compensation controller receives the command file in DXF or PLT format sent by the host computer software on the computer side through the serial port, USB port or network port. The composition of the instruction file includes: the coordinate sequence describing the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com