Electric motor for high-temperature applications

A technology of electric motors and high temperature, applied in the field of electric motors, can solve the problems of complex design, manufacturing and expensive operation of electric motors, and achieve the effect of cheap and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

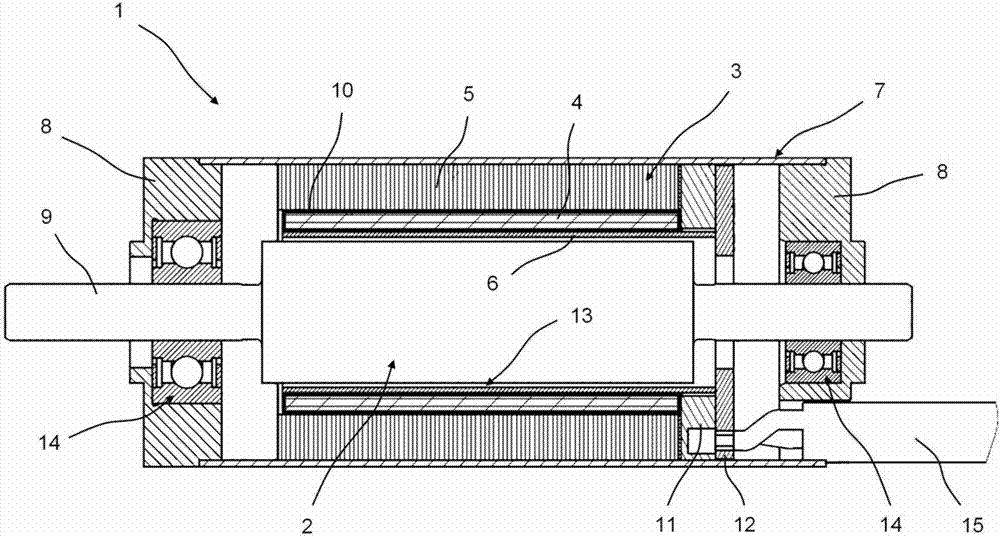

[0022] The electric motor 1 is designed as an inner rotor motor and comprises a rotor 2 and a hollow cylindrical stator 3 which is arranged coaxially with respect to the rotor and surrounds the inner rotor 2 . The inner rotor 2 is not shown in the illustrated section. The exact configuration of the rotor is not shown in further detail. The rotor comprises permanent magnets or a plurality of permanent magnet segments distributed over the circumference. The housing of the electric motor according to the invention, in which all the parts of the electric motor are housed, is indicated by reference number 7 in the figures. The housing 7 consists of a very simple hollow cylindrical sleeve, preferably of steel. A case cover 8 is provided at either end of the case 7 in the axial direction, and the case cover 8 seals the case 7 in the axial direction. Both housing covers 8 contain a ball bearing 14 each for rotatably mounting the shaft 9 of the inner rotor 2 .

[0023] The stator 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com