Implanting body with multiple-size surface structure and preparation method thereof

A surface structure and implant technology, applied in the medical field, can solve the problems of implant biocompatibility and insufficient bonding strength, and achieve the effects of improving mechanical chimerism and bonding strength, improving comprehensive performance, and shortening healing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

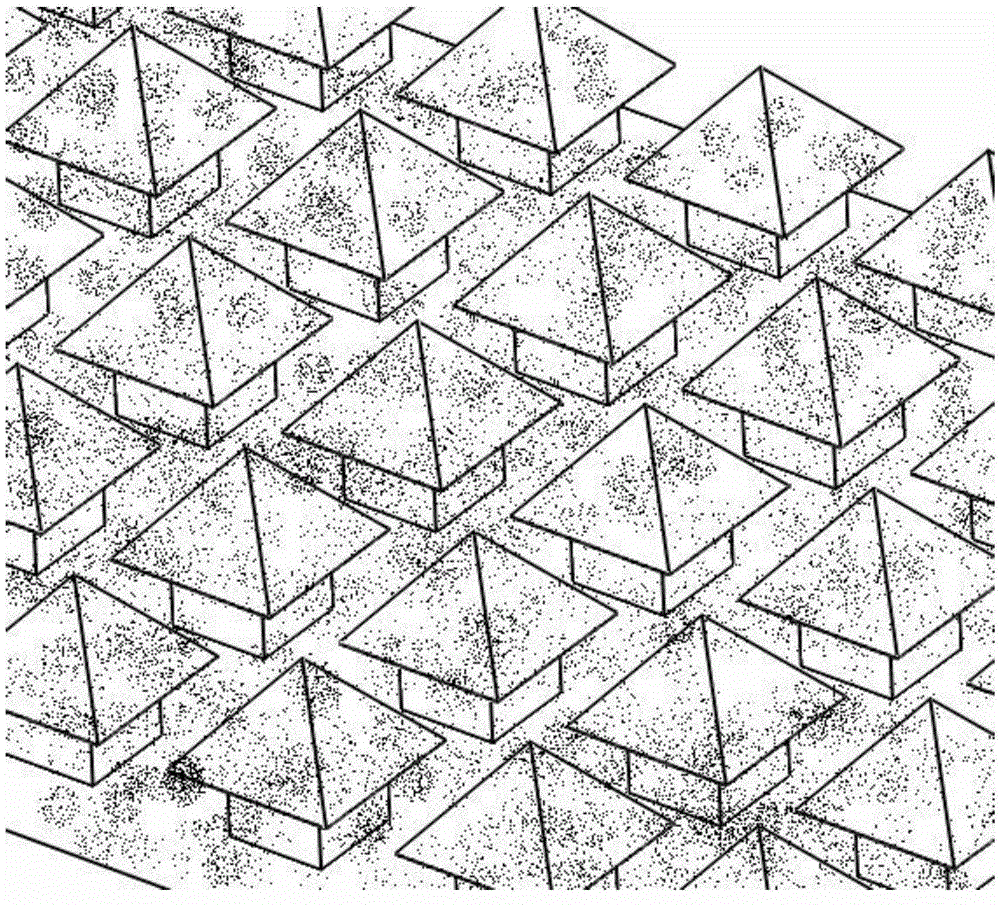

[0033] A multi-scale surface structure implant, which includes a micron-scale microstructure array, and the surface of the implant is covered with nanoscale holes with a diameter of 200nm, the microstructure array is a micro-pyramid array, a micro-barb array or a micro-groove any of the arrays.

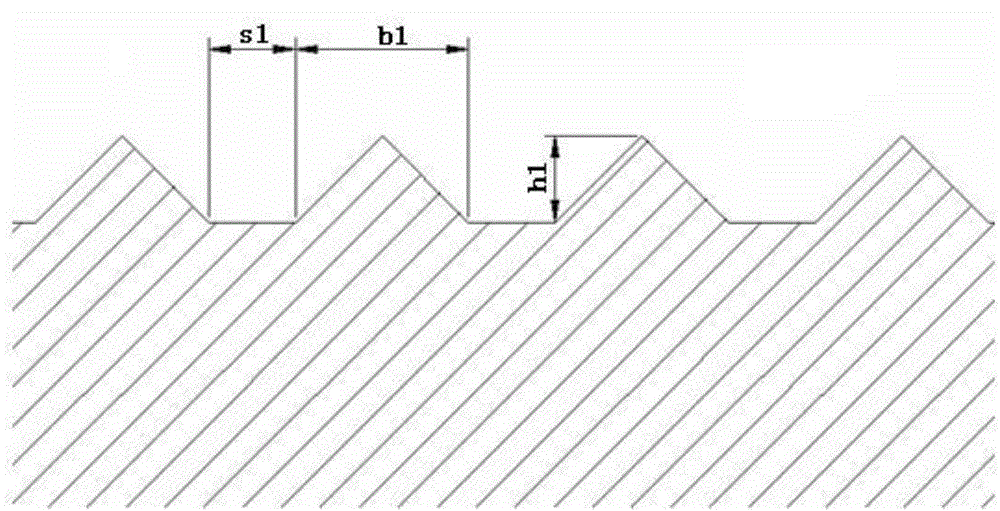

[0034] Wherein, the micro-pyramid array is several pyramids arranged equidistantly, and the longitudinal section of the pyramid is a triangle I; the base length b1 of the triangle I is 30 μm, the height h1 is 20 μm, and the distance s1 between two adjacent triangles I is 80 μm, the size of the pyramid is adapted to the placement of the implant, see figure 1 .

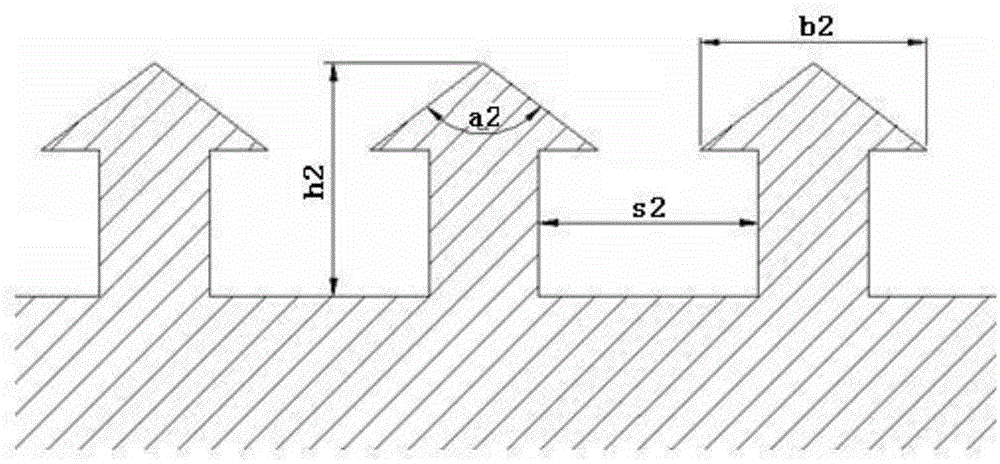

[0035] The micro-barb array is a number of barbs arranged equidistantly. The longitudinal section of the barb is a triangle II and a rectangle connected up and down. h2 is 100 μm, the distance s2 between two adjacent rectangles is 80 μm, the size of the barb is adapted to the implantation position of the implant, see figure...

Embodiment 2

[0045] A multi-scale surface structure implant, which includes a micron-scale microstructure array, and the surface of the implant is covered with nanoscale holes with a diameter of 500nm, and the microstructure array is a micro-pyramid array, a micro-barb array or a micro-groove any of the arrays.

[0046] Among them, the micro-pyramid array is several pyramids arranged equidistantly, and the longitudinal section of the pyramid is a triangle I; the base length b1 of the triangle I is 50 μm, the height h1 is 30 μm, and the distance s1 between two adjacent triangles I is 100 μm, the size of the pyramid is adapted to the placement of the implant, see figure 1 .

[0047] The micro-barb array is a number of barbs arranged equidistantly. The longitudinal section of the barb is a triangle II and a rectangle connected up and down. h2 is 400 μm, the distance s2 between two adjacent rectangles is 100 μm, the size of the barb is adapted to the implantation position of the implant, see...

Embodiment 3

[0057] A multi-scale surface structure implant, which includes a micron-scale microstructure array, and the surface of the implant is covered with nanoscale holes with a diameter of 400nm, the microstructure array is a micro-pyramid array, a micro-barb array or a micro-groove any of the arrays.

[0058] Wherein, the micro-pyramid array is several pyramids arranged equidistantly, and the longitudinal section of the pyramid is a triangle I; the base length b1 of the triangle I is 40 μm, the height h1 is 25 μm, and the distance s1 between two adjacent triangles I is 90 μm, the size of the pyramid is adapted to the placement of the implant, see figure 1 .

[0059] The micro-barb array is a number of barbs arranged equidistantly. The longitudinal section of the barb is a triangle II and a rectangle connected up and down. h2 is 250 μm, the distance s2 between two adjacent rectangles is 90 μm, the size of the barb is adapted to the implantation position of the implant, see figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bottom length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com