Platinoid bimetallic nanometer material and preparation method and application thereof

A bimetallic nano, platinum-copper technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

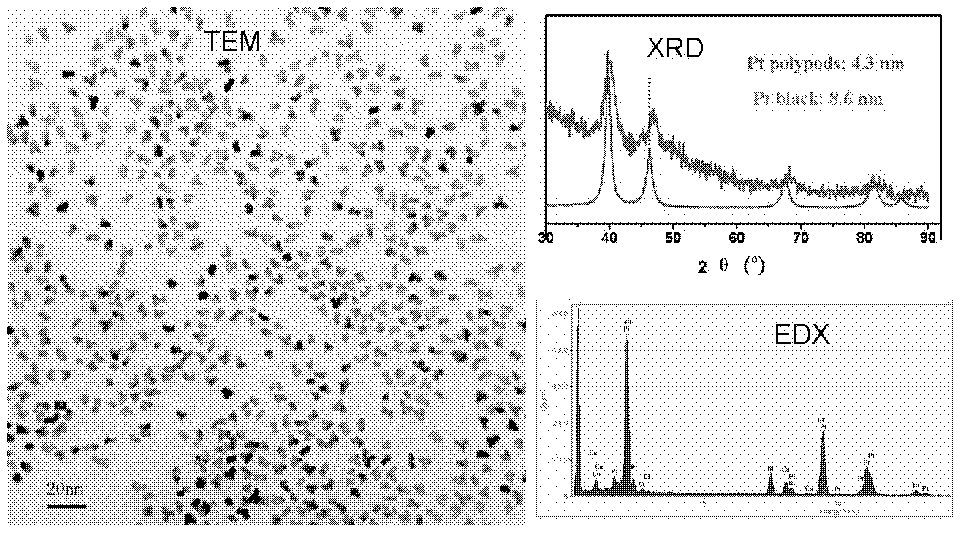

[0024] Weigh 110mg of PVP into a 25ml three-neck flask, add 0.8ml125mMCuCl 2 (AR) ethylene glycol solution, then add 8.55mL ethylene glycol, and start stirring at the same time to make it fully mixed and dissolved; slowly raise the temperature to 160°C in the air atmosphere, and after maintaining this temperature for 30 minutes, add H with a concentration of 77.3mM 2 PtCl 6 Solution 0.65mL solution was injected into 160℃ containing CuCl 2 In a hot solution of ethylene glycol, stir and react for 1 hour; transfer the reacted solution to a centrifuge tube, then add three times the volume of acetone, and centrifuge at 10,000rpm for 5min to obtain a platinum-copper multipod nanostructure, such as figure 1 , the size of the multipod structure is uniform, and the particle size of the synthesized nanoparticles is calculated by the Scherrer formula according to the XRD results to be 4.3nm.

[0025] The nanoparticles washed with water and ethanol were tested by EDX and ICP to obtain t...

Embodiment 2

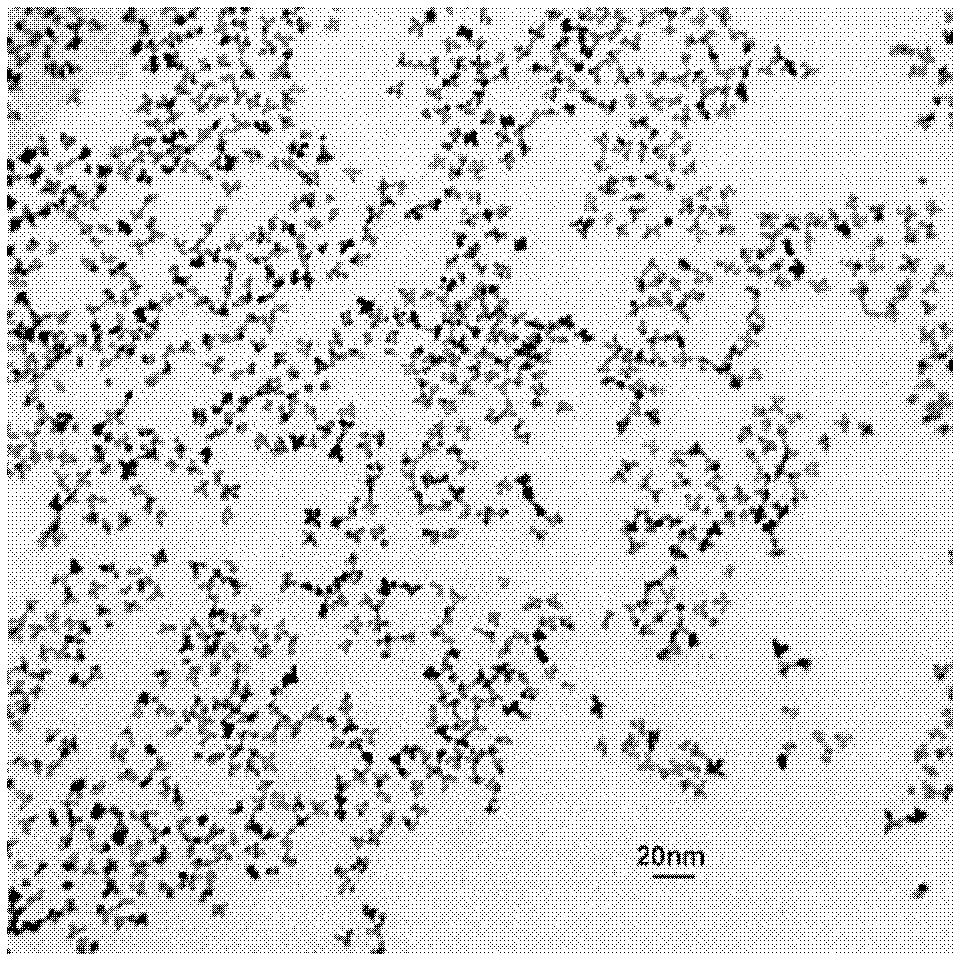

[0027] Weigh 110mg of PVP into a 25ml three-neck flask, add 0.8ml125mMCuCl 2 (99.999%) ethylene glycol solution, then add 8.55mL ethylene glycol, and start stirring at the same time to make it fully mix and dissolve; slowly heat up to 160°C in the air atmosphere, and after maintaining this temperature for 30 minutes, add 77.3mM h 2 PtCl 6 Solution 0.65mL solution was injected into 160℃ containing CuCl 2 In a hot solution of ethylene glycol, stir and react for 1 hour; transfer the reacted solution to a centrifuge tube, then add three times the volume of acetone, and centrifuge at 10,000rpm for 5min to obtain a platinum-copper multipod nanostructure, such as figure 2 , the multipod-like structure is uniform in size.

[0028] The nanoparticles washed with water and ethanol were tested by ICP to obtain a PtCu ratio of 3.7 / 1.

Embodiment 3

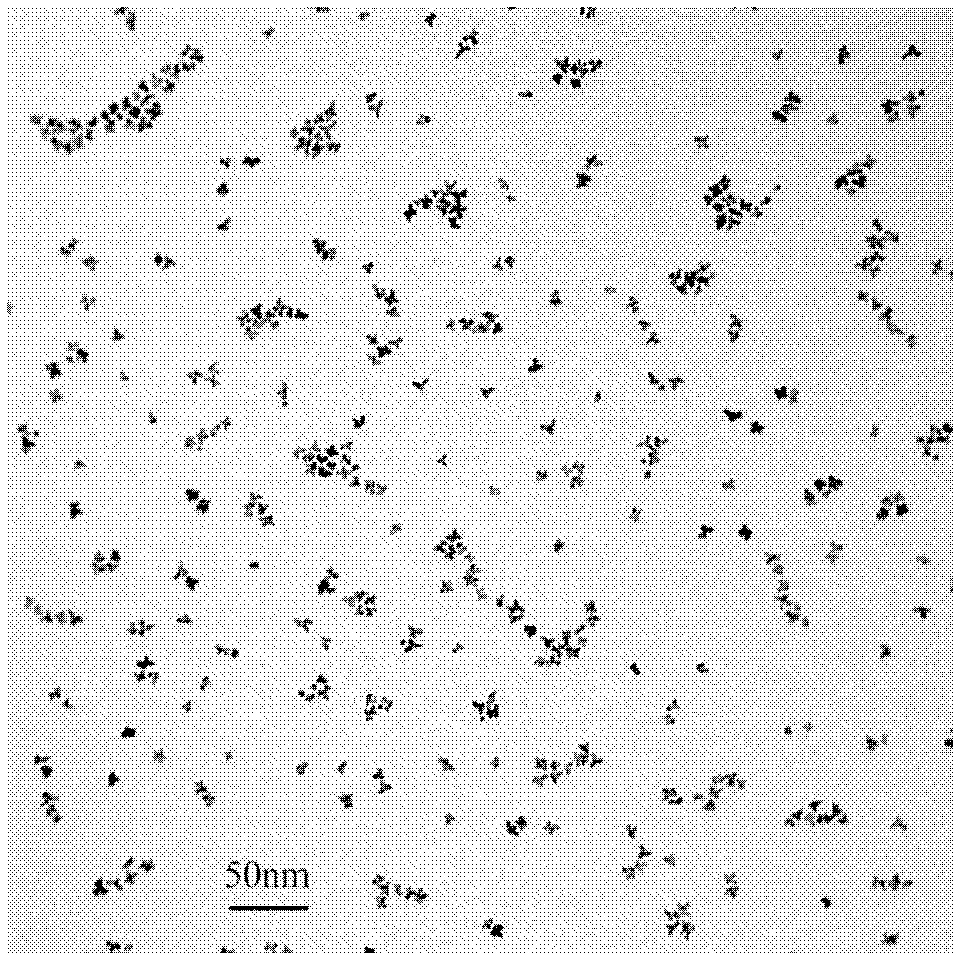

[0030] Weigh 110mg of PVP into a 25ml three-neck flask, add 0.8ml125mMCuCl 2 (99.999%) ethylene glycol solution, then add 8.55mL ethylene glycol, and start stirring at the same time to make it fully mixed and dissolved; slowly heat up to 160°C in an argon atmosphere, and after maintaining this temperature for 30 minutes, the concentration will be 77.3mM H 2 PtCl 6 Solution 0.65mL solution was injected into 160℃ containing CuCl 2 In a hot solution of ethylene glycol, stir and react for 1 hour; transfer the reacted solution to a centrifuge tube, then add three times the volume of acetone, and centrifuge at 10,000rpm for 5min to obtain a platinum-copper multipod nanostructure, such as image 3 , the multipod-like structure is uniform in size.

[0031] The nanoparticles washed with water and ethanol were tested by ICP to obtain that the PtCu ratio of the nanoparticles was 2.5 / 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com