Assembly tooling and assembly method for plunger slipper assembly for hydraulic plunger pump

A technology for assembling tooling and hydraulic columns, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as unbearable compression force and unsuitable sliding shoes, and achieve the effect of avoiding excessive clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

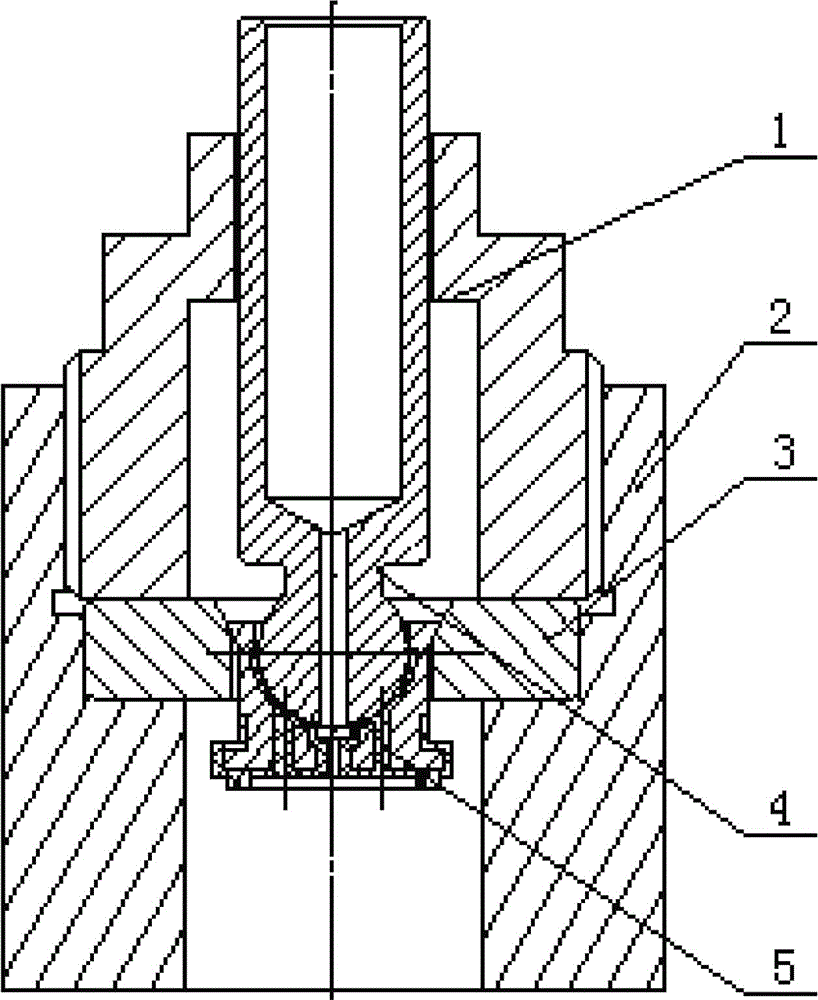

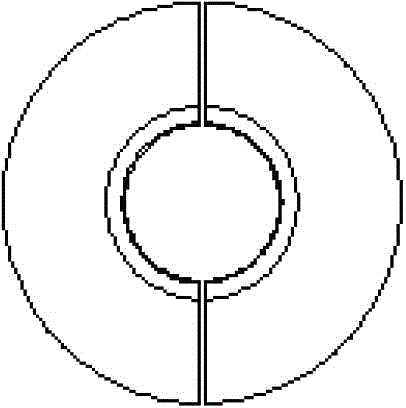

[0023] Such as Figure 1 to Figure 11 As shown, the assembly tooling used for the plunger slipper assembly of the hydraulic plunger pump includes a base 2, several sets of two semi-circular rings 3 of different sizes and a gland 1, the two semi-circular rings 3 is located in the cylindrical groove in the base 2, the gland 1 is against the semi-circular ring 3, and the gland 1 has a circular hole for the passage of the plunger 4, and the inner side of the semi-circular ring 3 is set There is a chamfer for matching with the groove at the end of the sliding shoe 5;

[0024] The invention relates to a processing method of a plunger sliding shoe assembly of a hydraulic plunger pump, comprising a plunger processing method, a sliding shoe processing method and a combined assembly method.

[0025] First of all, we use corrosion-resistant materials to process the plunger 4, roughly machine the outer circle and ball head of the plunger 4, drill a large hole at the tail, drill a small d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com