Bar Conveyor

A conveyor and bar technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of high labor intensity, high equipment cost and low efficiency, and achieve the effect of improving the degree of automation and production efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

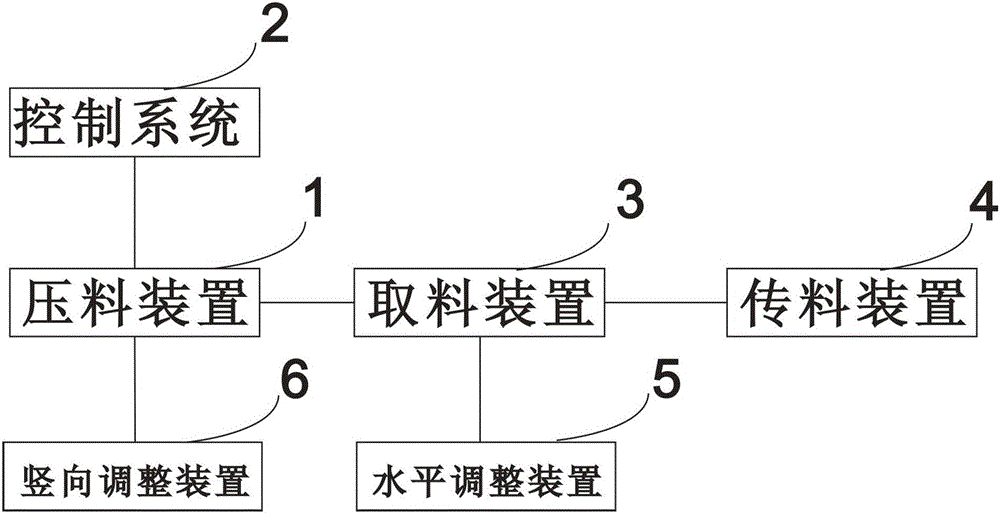

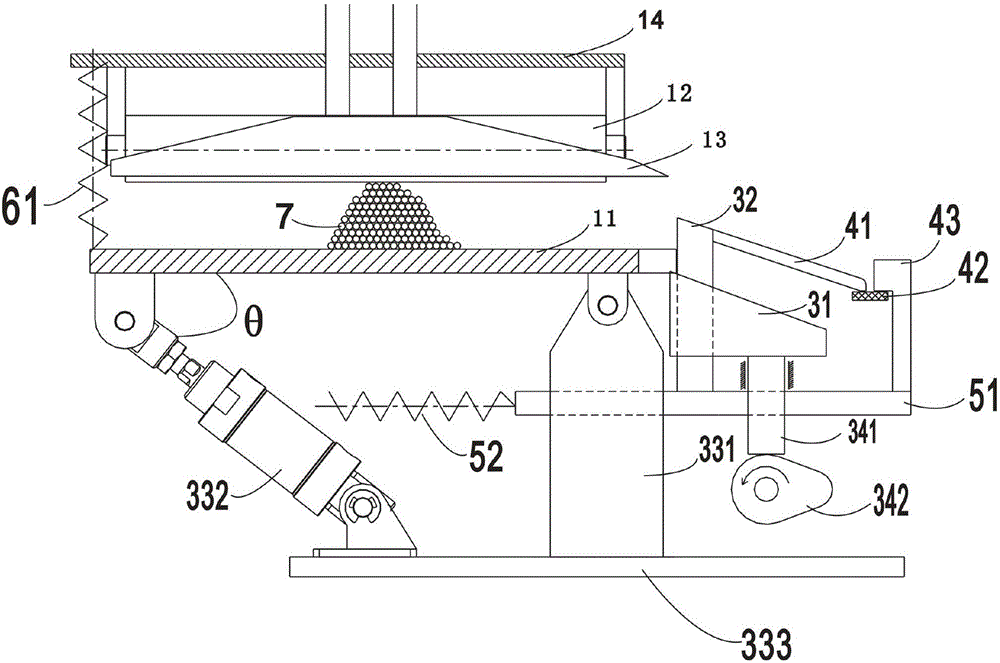

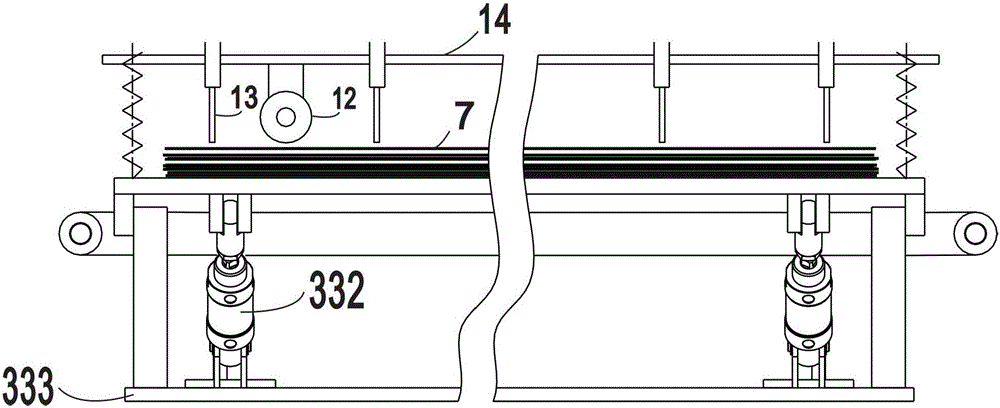

[0022] see figure 1 , figure 2 and image 3 , a bar conveyor, including a pressing device 1 for arranging the whole pile of multi-layer bars 7 into a single layer arrangement, a control system 2 for automatically controlling the pressing device, and a A retrieving device 3 for automatic single-root retrieving in the material device, a material transfer device 4 for transferring material from the reclaiming device, and an adjustment device for adjusting the bar specification; the adjustment device includes a bar specification The horizontal adjustment device 5 and the vertical adjustment device 6, the horizontal adjustment device 5 is connected with the material taking device 3, and the vertical adjustment device 6 is connected with the pressing device 1.

[0023] The pressing device 1 includes a tray 11 for placing the whole pile of multi-layer bars, a monolithic bar 12 for arranging the whole pile of multi-layer bars 7 into a single-layer arrangement, and a single-layer ar...

Embodiment 2

[0036] The difference from Embodiment 1 is that the reclaiming power device includes a power screw (not shown) connected to the reclaiming fork, and a second cylinder (not shown) for driving the power screw to move up and down Or a motor (not shown), so that the up and down motion of the reclaiming fork is driven by the second cylinder or the motor driving the power screw mandrel.

Embodiment 3

[0038] see Figure 5 , different from Embodiment 1, the level adjustment device includes a horizontal slide plate 51, a horizontal screw rod 52 fixedly connected with the horizontal slide plate, a graduated handwheel 53 connected with the horizontal screw rod, which can be achieved through low-cost Scaled handwheel for quick and accurate adjustment of individual extractions for bar sizes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com