Purifying and refining method of 1,5-dihydroxynaphthalene

A technology of dihydroxynaphthalene and a purification method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as no literature reports on the purification and purification method of 1.5-dihydroxynaphthalene, and reduce tar formation. fouling, simple process, reducing the effect of high temperature coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

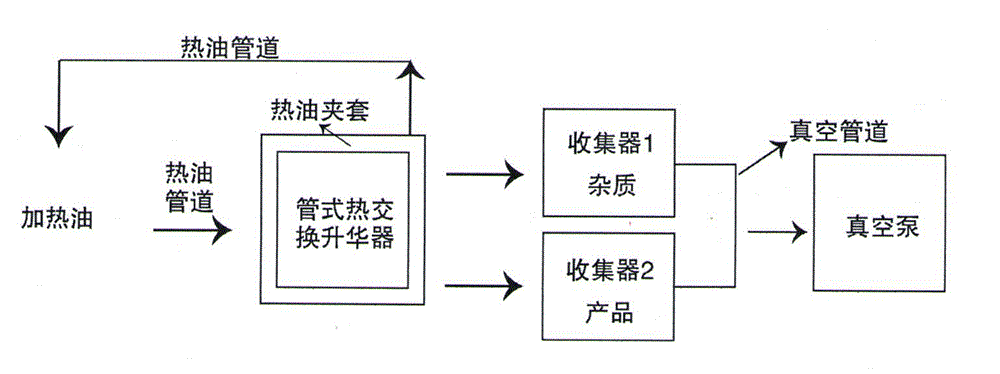

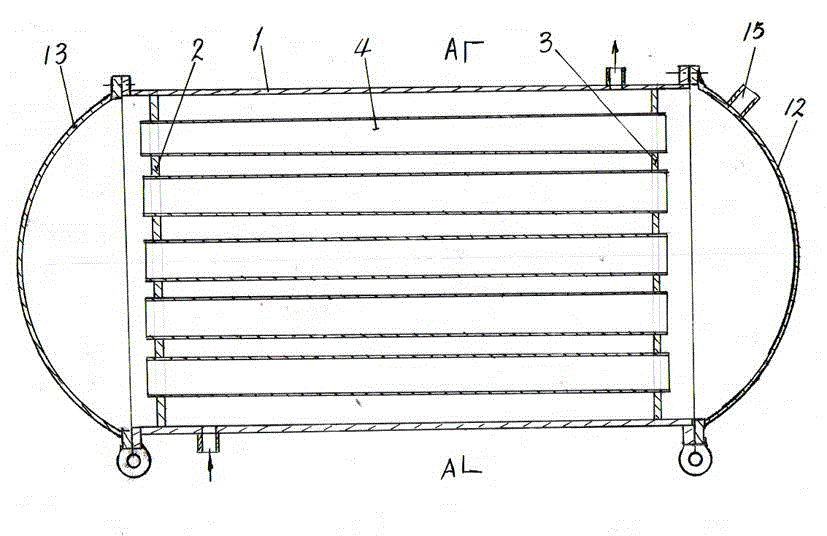

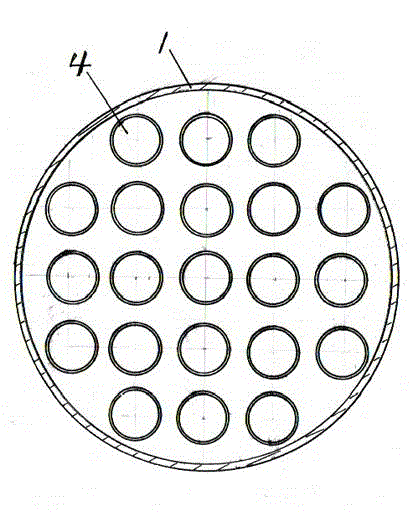

[0033] 1) Equipment used, heating oil equipment, horizontal tubular heat exchange sublimator, first collector, second collector, vacuum pump equipment, heating oil equipment and horizontal tubular heat exchange sublimator through hot oil inlet and outlet pipes connection, implement hot oil circulation heating work on the tubular heat exchange sublimator, the horizontal tubular heat exchange sublimator consists of a cylinder 1, a front partition 2 welded in the cylinder 1, a rear partition 3, distributed inserts A number of heat exchange tubes 4 welded on the front and rear partitions 2 and 3, a sealed heating oil chamber is formed between the front partition 2 and the rear partition 3 and the cylinder body 1, the front end or rear end of the cylinder body 1, or the cylinder body The front and rear ends of 1 are provided with hingedly connected openable sealing end caps 12, 13, and a distillation outlet pipe 15 and a control valve are provided on the sealing end caps 12 / 13 to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com