Solid-phase synthesis method of ularitide

A solid-phase synthesis method and a technology for uralibide, which are applied in the field of solid-phase synthesis of uralibide, can solve the problems of no industrialized method for preparing uralibide, etc., and achieve the effects of low production cost, simple operation and stable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

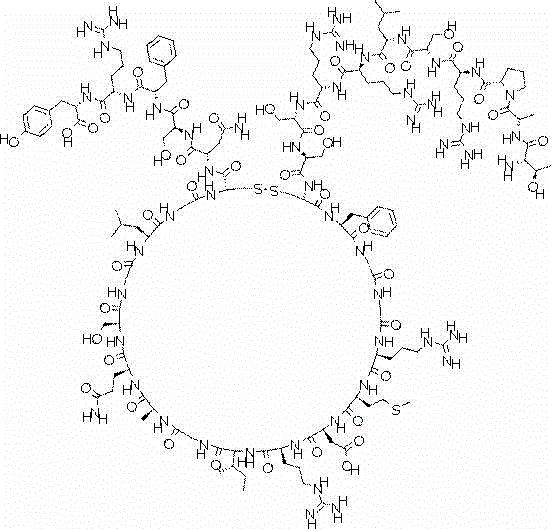

Image

Examples

Embodiment 1

[0064] 1) Preparation of Fmoc-Arg(pbf)-Tyr(tbu)-King resin

[0065] Weigh 47.6 grams of Fmoc-Tyr(tbu)-King resin (0.42mmol / g, 20mmol), soak it with 800ml DMF for 30 minutes, fully swell the resin, drain it, add Fmoc-Arg(pbf)-OH (MW:648.8 , 60mmol) 38.9g, TBTU (MW: 321.1, 60mmol) 19.3g, HOBT (MW: 135.1, 60mmol) 8.1g, DIEA (MW: 129.24, 120mmol) 20ml, DMF500ml, reacted for 1.5 hours, ninhydrin detection resin without The color was transparent, drained, washed 3 times with DMF, and drained to obtain Fmoc-Arg(pbf)-Tyr(tbu)-King resin.

[0066] 2) Preparation of Thr(tbu)-Ala-Pro-Arg(pbf)-Ser(tbu)-Leu-Arg(pbf)-Arg(pbf)-Ser(tbu)-Ser(tbu)-Cys(Trt)-Phe -Gly-Gly-Arg(pbf)-Met-Asp(Otbu)-Arg(pbf)-Ile-Gly-Ala-Gln(Trt)-Ser(tbu)-Gly-Leu-Gly-Cys(Trt)-Asn (Trt)-Ser(tbu)-Phe-Arg(pbf)-Tyr(tbu)- Wang resin.

[0067] In the Fmoc-Arg(pbf)-Tyr(tbu)-King resin obtained in step (1), add 800ml decapping reagent (20% PIP / DMF(v / v) solution), react for 30 minutes, drain, and use Wash with DMF 6 times, d...

Embodiment 2

[0106] 1) Preparation of Fmoc-Arg(pbf)-Tyr(tbu)-King resin

[0107]Weigh 57.1 grams (0.35mmol / g, 20mmol) of Fmoc-Tyr(tbu)-King resin, soak it with 800ml DMF for 30 minutes, fully swell the resin, drain it, add Fmoc-Arg(pbf)-OH (MW:648.8 , 40mmol) 26.0g, HBTU (MW: 379.2, 40mmol) 15.2g, HOBT (MW: 135.1, 40mmol) 5.4g, NMM (MW: 102.1, 80mmol) 9.0ml, DMF500ml, react for 1 hour, ninhydrin detection resin Colorless and transparent, drained, washed 3 times with DMF, and drained to obtain Fmoc-Arg(pbf)-Tyr(tbu)-King resin.

[0108] 2) Preparation of Thr(tbu)-Ala-Pro-Arg(pbf)-Ser(tbu)-Leu-Arg(pbf)-Arg(pbf)-Ser(tbu)-Ser(tbu)-Cys(Trt)-Phe -Gly-Gly-Arg(pbf)-Met-Asp(Otbu)-Arg(pbf)-Ile-Gly-Ala-Gln(Trt)-Ser(tbu)-Gly-Leu-Gly-Cys(Trt)-Asn (Trt)-Ser(tbu)-Phe-Arg(pbf)-Tyr(tbu)- Wang resin.

[0109] In the Fmoc-Arg(pbf)-Tyr(tbu)-King resin obtained in step (1), add 800ml decapping reagent (20% PIP / DMF(v / v) solution), react for 30 minutes, drain, and use Wash with DMF 6 times, drain, use DMF a...

Embodiment 3

[0148] 1) Preparation of Fmoc-Arg(pbf)-Tyr(tbu)-King resin

[0149] Weigh 43.5 grams of Fmoc-Tyr(tbu)-King resin (0.46mmol / g, 20mmol), soak it with 800ml DMF for 30 minutes, fully swell the resin, drain it, add Fmoc-Arg(pbf)-OH (MW:648.8 , 40mmol) 26.0g, HATU (MW: 380.2, 40mmol) 15.2g, HOAT (MW: 136.1, 40mmol) 5.4g, NMM (MW: 102.1, 80mmol) 9.0ml, DMF500ml, reacted for 0.5 hours, ninhydrin detection resin Colorless and transparent, drained, washed 3 times with DMF, and drained to obtain Fmoc-Arg(pbf)-Tyr(tbu)-King resin.

[0150] 2) Preparation of Thr(tbu)-Ala-Pro-Arg(pbf)-Ser(tbu)-Leu-Arg(pbf)-Arg(pbf)-Ser(tbu)-Ser(tbu)-Cys(Trt)-Phe -Gly-Gly-Arg(pbf)-Met-Asp(Otbu)-Arg(pbf)-Ile-Gly-Ala-Gln(Trt)-Ser(tbu)-Gly-Leu-Gly-Cys(Trt)-Asn (Trt)-Ser(tbu)-Phe-Arg(pbf)-Tyr(tbu)- Wang resin.

[0151] In the Fmoc-Arg(pbf)-Tyr(tbu)-King resin obtained in step (1), add 800ml decapping reagent (20% PIP / DMF(v / v) solution), react for 30 minutes, drain, and use Wash 6 times with DMF, drain, use DM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com