Novel method for removing indole in oil product through ionic liquid

A technology of ionic liquid and new method, which is applied in the direction of refining with acid-containing liquid, etc., can solve the problems of non-reusable catalyst, large waste water discharge, and large consumption, so as to overcome the problem of non-reusable use, reduce production cost, and simple reaction conditions easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

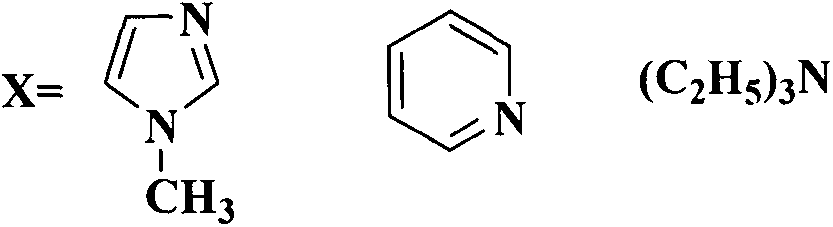

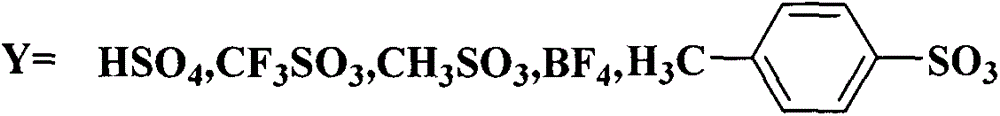

Method used

Image

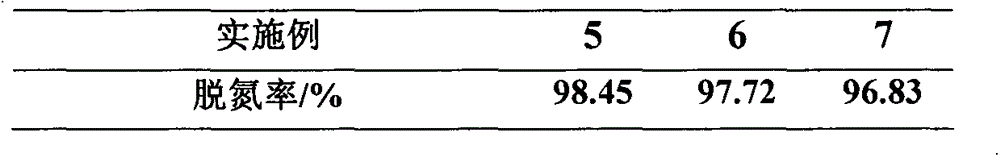

Examples

Embodiment 1

[0020] Embodiment 1: get 10g containing indole analog oil product (N%=150ppm) in reaction bottle, add 10mmol (C 2 h 5 ) 3 N(CH 2 ) 3 SO 3 HHSO 4 1.6g of deionized water, stirred and reacted at 40°C for 2h, after the reaction was completed, the reaction liquid settled for 24h, and the nitrogen content of the upper layer oil was measured, and the denitrification rate was 98.70%.

Embodiment 2

[0021] Embodiment 2: experimental condition and step are with embodiment 1, just change ionic liquid into (C 2 h 5 ) 3 N(CH 2 ) 3 SO 3 HCF 3 SO 3 , The denitrification rate is 98.68%.

Embodiment 3

[0022] Embodiment 3: experimental condition and step are with embodiment 1, just change ionic liquid into (C 2 h 5 ) 3 N(CH 2 ) 3 SO 3 HCH 3 SO 3 , The denitrification rate is 96.17%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com