Method for preparing collagen/lactic acid-caprolactone copolymer composite fiber bracket

A collagen and composite fiber technology, applied in the fields of medical science, textiles and papermaking, prostheses, etc., can solve the problem of not fully meeting the requirements of cell growth, and achieve the effect of promoting cell growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

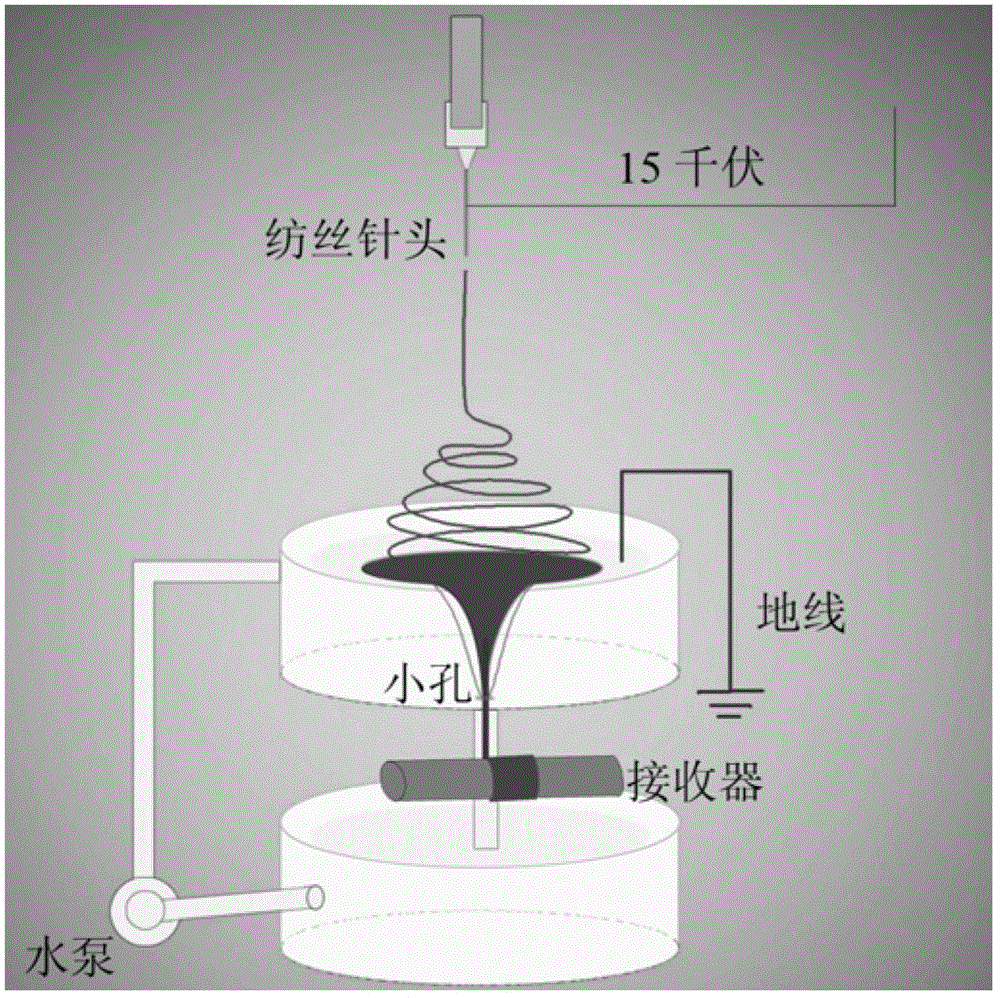

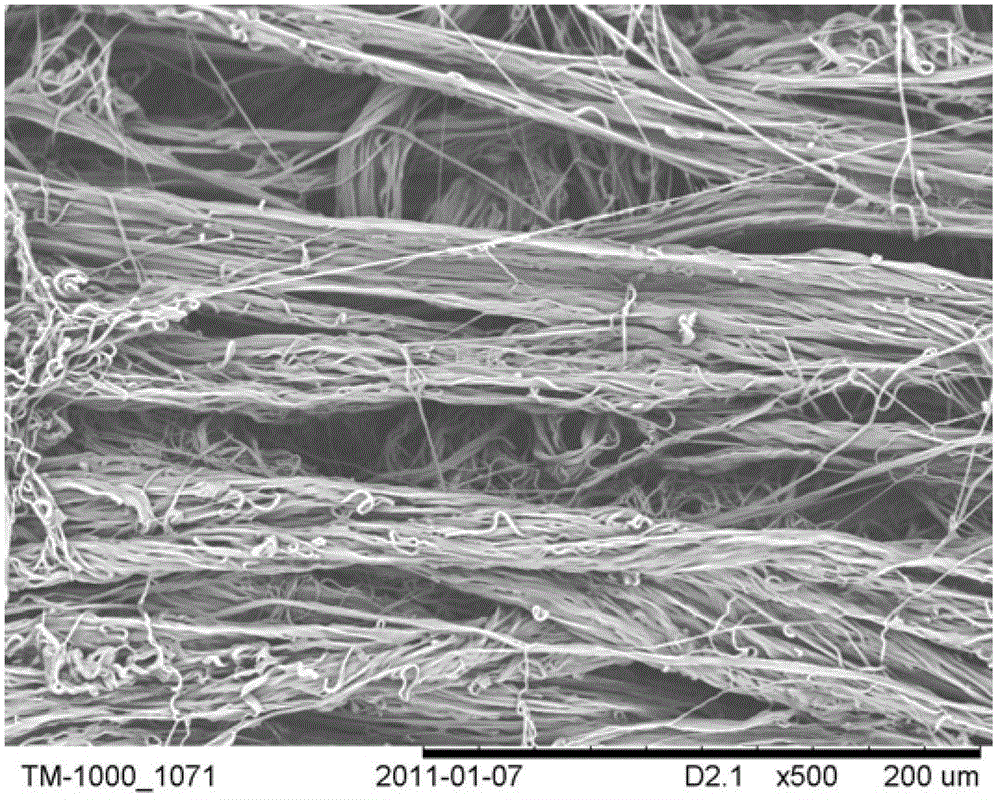

[0022] Dissolve 0.8 g of collagen in 10 ml of hexafluoroisopropanol and stir until uniform to obtain a collagen solution with a concentration of 8% (g / ml); dissolve 0.8 g of polylactic acid-caprolactone copolymer in 10 ml In hexafluoroisopropanol, stir until uniform to obtain a lactic acid-caprolactone copolymer solution with a concentration of 8% (g / ml); mix the two solutions at a volume ratio of 10:90 to obtain collagen and lactic acid- A mixed solution with a caprolactone copolymer mass ratio of 10:90; the mixed solution was subjected to electrospinning, spinning conditions: voltage, 15 kV; electric field distance, 150 mm; injection rate, 1 ml / hour; shaft speed, 60 rotation / minute; the diameter of the small hole is 8 mm, and the composite fiber scaffold is obtained. The nanofibers in the scaffold have an average diameter of 650 nanometers, and the microfibers have an average diameter of 24 micrometers.

Embodiment 2

[0024] Dissolve 0.8 g of collagen in 10 ml of hexafluoroisopropanol and stir until uniform to obtain a collagen solution with a concentration of 8% (g / ml); dissolve 0.8 g of lactic acid-caprolactone copolymer in 10 ml of hexafluoroisopropanol In fluoroisopropanol, stir until uniform to obtain a polylactic acid-polycaprolactone solution with a concentration of 8% (g / ml); mix the two solutions at a volume ratio of 25:75 to obtain collagen and lactic acid-caprolactone A mixed solution with a lactone copolymer mass ratio of 25:75; electrospinning the mixed solution, spinning conditions: voltage, 15 kV; electric field distance, 150 mm; injection rate, 1 ml / hour; shaft speed, 60 rpm / min; the diameter of the small hole is 8 mm, and the composite fiber support is obtained. The nanofibers in the scaffold have an average diameter of 542 nanometers, and the microfibers have an average diameter of 20 micrometers.

Embodiment 3

[0026] Dissolve 0.8 g of collagen in 10 ml of hexafluoroisopropanol solution and stir until uniform to obtain a collagen solution with a concentration of 8% (g / ml); dissolve 0.8 g of lactic acid-caprolactone copolymer in 10 ml Hexafluoroisopropanol solution, stirred until uniform to obtain a lactic acid-caprolactone copolymer solution with a concentration of 8% (g / ml); mix the two solutions at a volume ratio of 40:60 to obtain collagen and poly A mixed solution with a mass ratio of lactic acid-polycaprolactone of 40:60; electrospinning the mixed solution, spinning conditions: voltage, 15 kV; electric field distance, 150 mm; injection rate, 1 ml / hour; shaft speed, 60 revolutions / minute; the diameter of the small hole is 8 mm, and the composite fiber scaffold is obtained. The nanofibers in the scaffold have an average diameter of 450 nanometers, and the microfibers have an average diameter of 15 micrometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com