Forming method of medium-deep dacron face fabric

A polyester and fabric technology, applied in the field of fabric processing, can solve problems such as color fastness decline, deterioration, polyester fabric specifications and fabric creases that cannot meet the requirements, etc., to achieve high color fastness and smooth fabric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

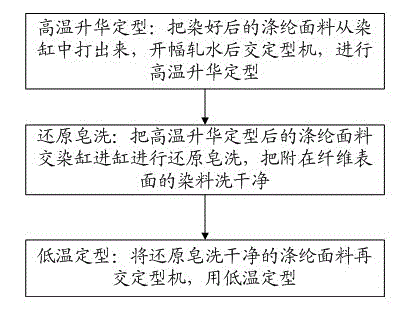

[0023] The dyed polyester fabric is punched out from the dye vat, and then handed over to a setting machine for 190°C high-temperature sublimation for setting after the water is squeezed. Put the cloth after high-temperature setting into the vat for reduction soaping, and wash away the dye attached to the surface of the fiber. Soap the clean fabric and then hand it in for setting at a low temperature of 130°C.

[0024] High temperature sublimation: the disperse dyes will also sublimate the dyed polyester fabric under the action of high temperature. Under the action of high temperature, the polyester fiber will expand and the disperse dye molecules will overflow inside the fiber.

[0025] In the method for setting the shape of the dark polyester fabric in the present invention, the dyed polyester fabric is subjected to high-temperature sublimation, so that the dyed fiber molecular structure is re-arranged so as to reach a relatively stable state. Do a reduction soaping in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com