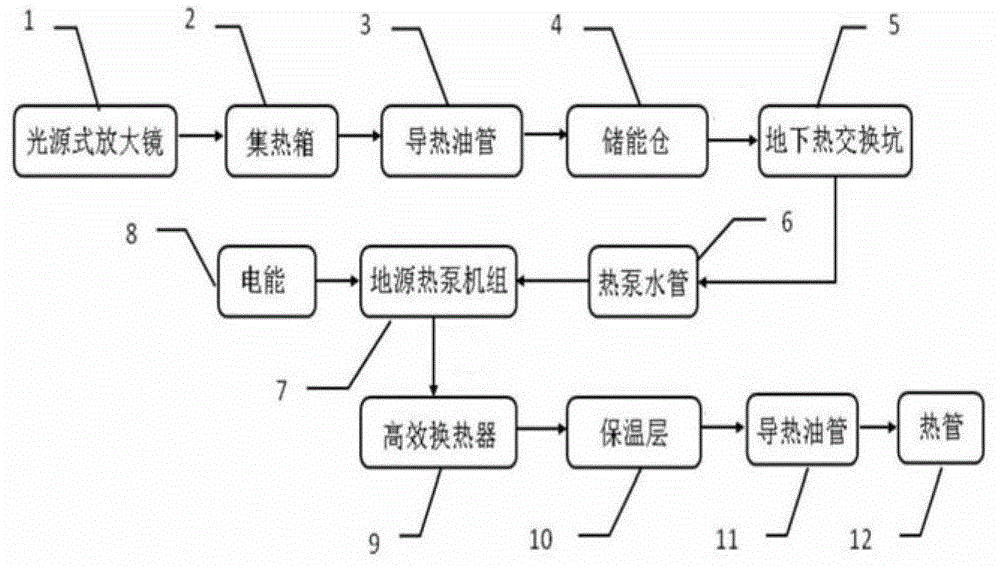

Solar snow melting system

A technology of solar energy and energy storage systems, applied to roads, pavement details, roads, etc., to achieve high-efficiency heat exchange, heat mass transfer, low cost, stable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

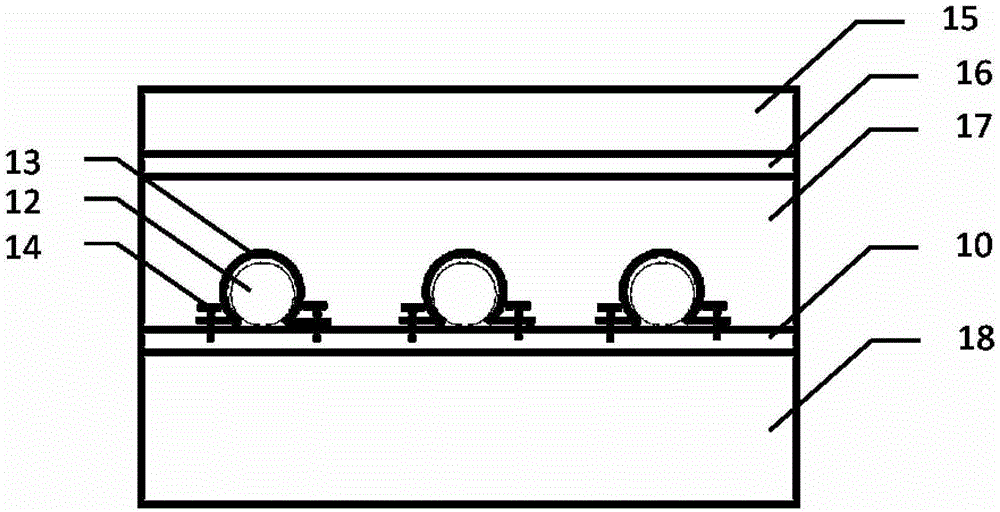

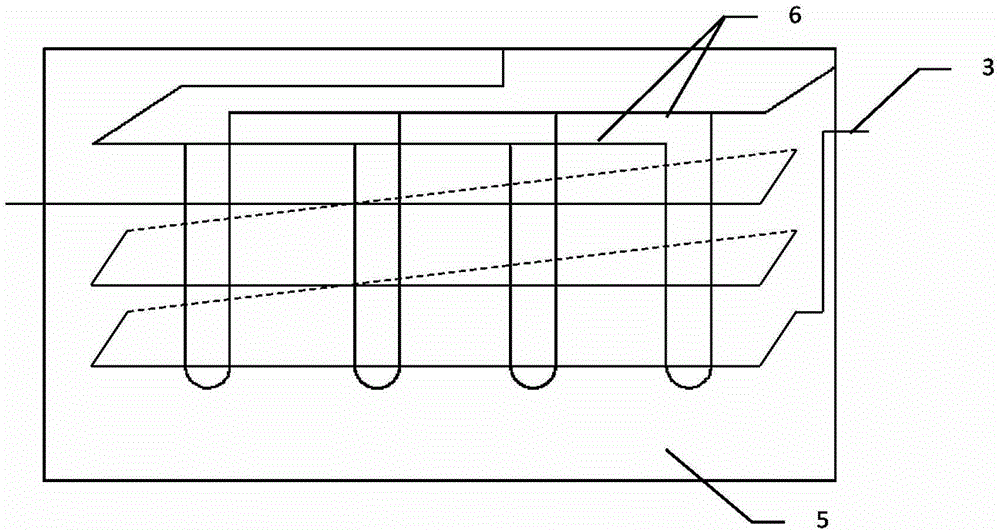

[0023] Embodiment: As shown in the figure, a solar snow melting system, the automatic tracking light source type magnifying glass 1 is installed on the outside of the heat collection box 2, and a plurality of interconnected heat conduction oil pipes 3 are installed in the heat collection box 2, and the energy storage bin 4 A plurality of interconnected heat-conducting oil pipes 3 are also installed, and the output end of the heat-conducting oil pipe 3 in the heat collecting tank 2 is connected with the input end of the heat-conducting oil pipe 3 in the energy storage bin 4. The heat-conducting oil pipe 3 is coiled on the bottom, the input end of the heat-conducting oil pipe 3 in the underground thermal insulation heat exchange pit 5 is connected to the output end of the thermal oil pipe 3 in the energy storage bin 4, and the output end of the thermal oil pipe 3 in the underground thermal insulation heat exchange pit 5 is connected to the The input end of the heat conduction oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com