Cylinder wall variable heat conduction structure

A heat conduction structure and variable technology, applied in cylinders, cylinder heads, engine components, etc., can solve the problems of increased frictional resistance, increased mechanical friction loss, increased heat dissipation loss, etc., to achieve safe heat dissipation and reduce fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

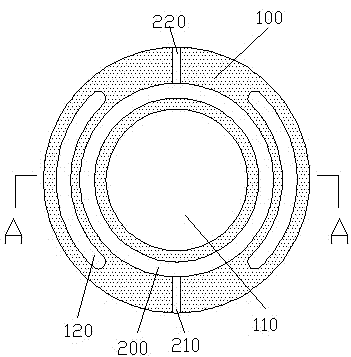

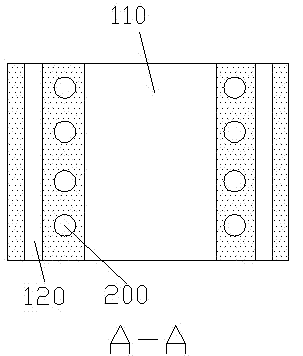

[0019] refer to figure 1 , in this embodiment, the variable heat conduction structure of the cylinder wall includes a cylinder body 100, and the cylinder body 100 is provided with a cylinder block 110 for accommodating the movement of the piston. The cooling passage 120, a heat conduction switching member for switching heat conduction substances is also arranged between the cooling passage 120 and the cylinder body 110.

[0020] refer to figure 1 , it can be seen from the figure that the cooling channels 120 are evenly distributed on both sides of the cylinder block.

[0021] refer to figure 2 , the heat conducting member includes several turns of heat exchange pipes 200 surrounding the cylinder block 110, and each heat exchange pipe 200 is provided with at least one switching channel 210, 220 on the cylinder body 100, and the switching channel 210 , 220 transport working fluids with different thermal conductivity through a pump body (not shown).

[0022] Through the func...

Embodiment 2

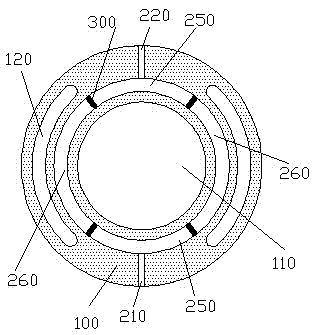

[0024] refer to image 3 , in this embodiment, based on the structure of Embodiment 1, the heat exchange pipe 200 contains two working fluids with different thermal conductivity, and the working fluids are divided by a rodless piston 300, by changing the cooling The working medium in the part of the heat exchange pipe 200 between the channel 120 and the cylinder 110 changes the heat conduction efficiency between the cylinder 110 and the cooling channel 120 .

[0025] The use of the rodless piston 300 prevents interference between different working fluids, makes the working area distinction between the working fluids more obvious, and facilitates precise adjustment of the heat conduction efficiency between the cylinder block 110 and the cooling channel 120 .

[0026] In the cooling state of the engine, the heat exchange pipe 200 is divided into four sections by the rodless piston 300, and the four sections include two sections 250 of high thermal conductivity working fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com