Stainless steel piston pump for filling

A technology of stainless steel and piston pumps, applied in pumps, pump devices, pump components, etc., can solve the problems of poor quantitative accuracy, affecting the service life of rubber pistons, and wear of the outer surface of rubber pistons, achieving high filling accuracy and improving work The effect of filling efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

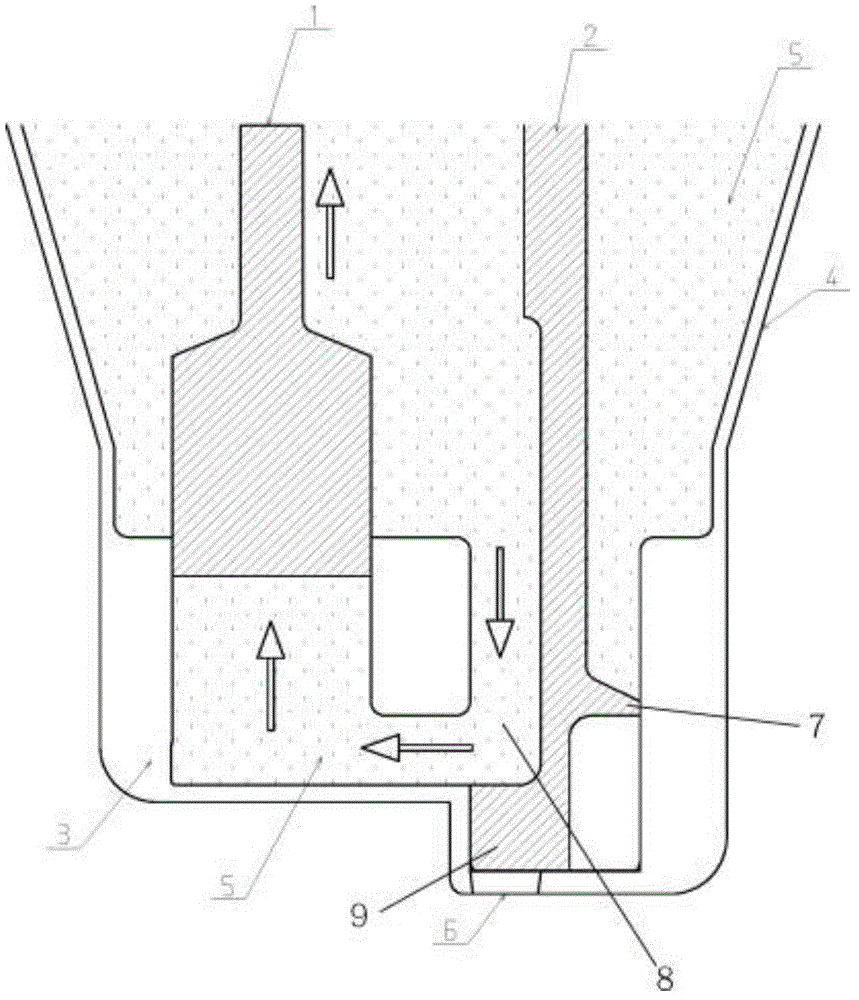

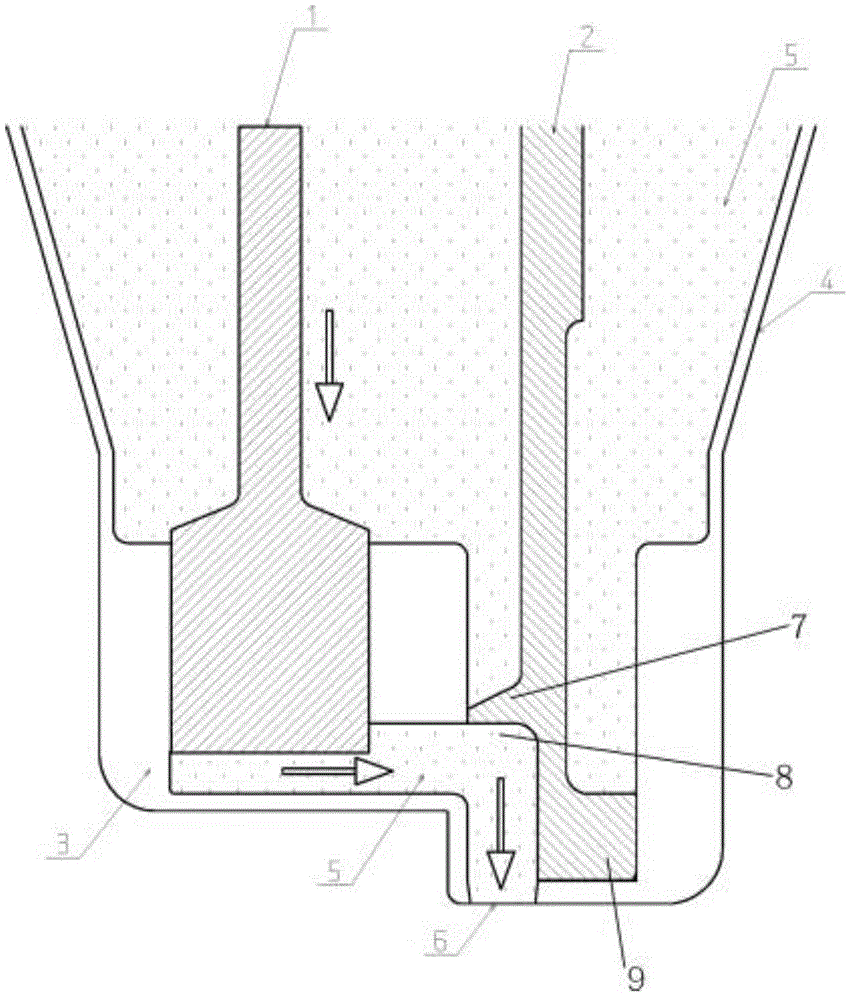

[0016] Such as figure 1 with figure 2 Shown is the structure diagram of the stainless steel piston pump for filling in the present invention in two working states.

[0017] Wherein, the piston 1 has a cylindrical structure and is made of stainless steel. The piston 1 reciprocates in the piston cylinder 3, works on the liquid 5 to be filled through the bottom surface, and pumps the liquid 5 to be filled into the packaging container through the liquid outlet 6. , the side of the piston 1 directly contacts the liquid 5 to be poured, thereby forming a back pressure to achieve a sealing effect, and the piston 1 and the piston cylinder 3 are built in the piston chamber of the liquid buffer tank 4 .

[0018] The rotary valve 2 is provided with an outlet stopper 9 for controlling the opening and closing of the liquid outlet 6 and an inlet stopper 7 for controlling the opening and closing of the liquid inlet 8 .

[0019] The liquid buffer tank 4 is used to store the liquid to be pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com