Device for mechanical performance test of flexible device

A technology of mechanical properties and testing equipment, applied in the field of bending testing, can solve problems such as inability to ensure uniform bending, bending angle, and easy damage to thin-film devices, and achieve the effects of convenient testing, low cost, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

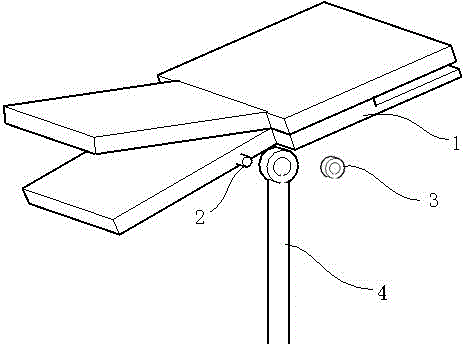

[0027] Such as figure 1 As shown, drill a through hole with a diameter of 2 mm in an ordinary plastic flat clamp about 5 mm away from the shaft, insert a metal shaft with a diameter of 2 mm and a length of 20 mm in the through hole, and insert a metal shaft with a diameter of 2 mm and a length of 2 mm. A 20mm metal shaft is inserted into a plastic tee rod 4, and a bearing with an inner diameter of 2mm is installed in the through hole of the tee rod.

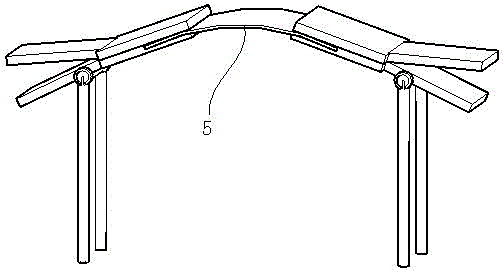

[0028] Such as figure 2 As shown, for the fixed part of the flexible substrate, one of the two refitted clips is installed on the fixed end on the fixed base plate, and the other is installed on the slide table 6 that can automatically move back and forth.

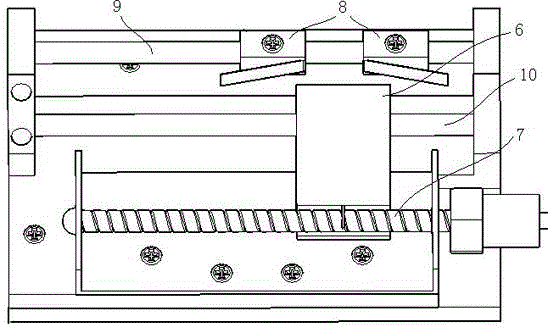

[0029] The overall effect of the flexible testing equipment of the present invention is as follows: Figure 5 As shown, the sliding table 6, the fixed bottom plate 13 and other mechanical parts are made of polyvinyl chloride (PVC), high-quality mahogany and other materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com