Activated calcium analyzer for steelmaking in steelmaking

A technology of active calcium and analyzer, applied in analytical materials, instruments, scientific instruments, etc., can solve the problems of lack of active calcium quantitative analysis, affecting the accuracy of analysis results, uneven sample particle size, etc., achieving good constant temperature effect and wide application Sex, easy to promote the effect of popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

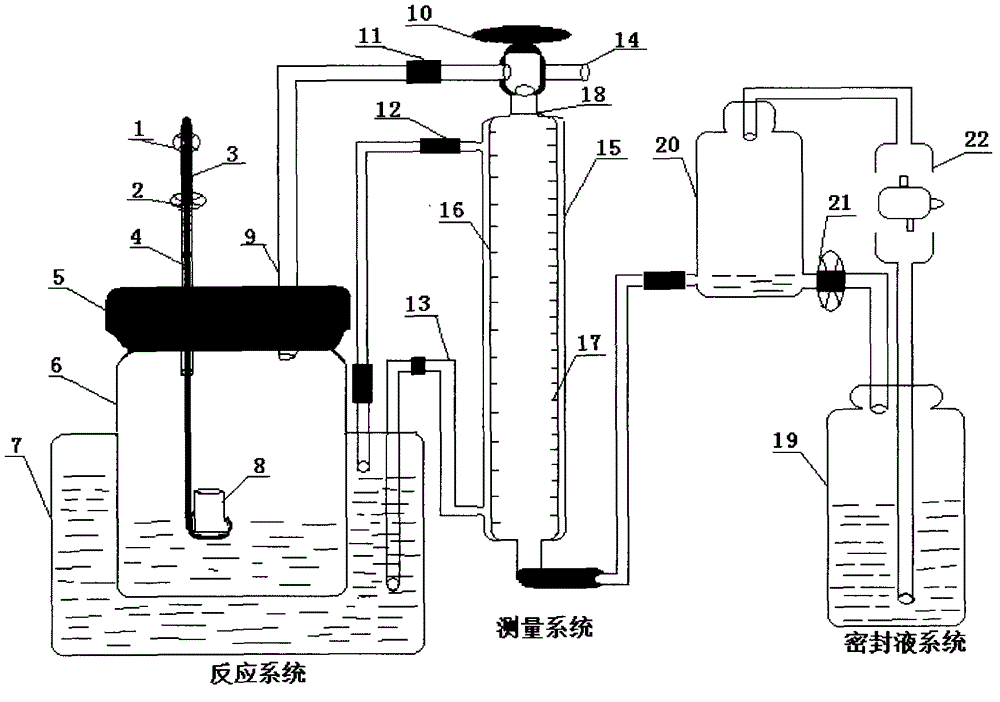

[0012] Below in conjunction with accompanying drawing, the present invention's using method is described in detail:

[0013] Before the analysis of calcium additives, the special reaction vessel needs to be placed in a super constant temperature water bath. All pipelines in the system are connected with rubber hoses, the circulating water constant temperature device is turned on, and the tightness of the system is checked.

[0014] Put a certain amount of material to be analyzed into the sample cup (8), fix the sample cup on the controllable sampling rod (4), the spring clip (1) and the spring clip (2) clamp the controllable sample injection Move the upper end of the rod (4) into the special reactor (6) filled with distilled water in advance, tighten the built-in rubber plug sealing cover (5), turn the ground two-way cock (10) on the top of the trachea to make the thermostat trachea (15) Communicate with the exhaust hole (14), lift the liquid level of the level bottle (20) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com