Low-temperature material linear expansion coefficient measuring method and low-temperature material linear expansion coefficient measuring device

A technology of expansion coefficient and measuring device, which is applied in the direction of thermal expansion coefficient of materials, can solve problems such as manufacturing process differences, and achieve the effects of accurate thermal expansion coefficient value, easy construction, and simple experimental principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

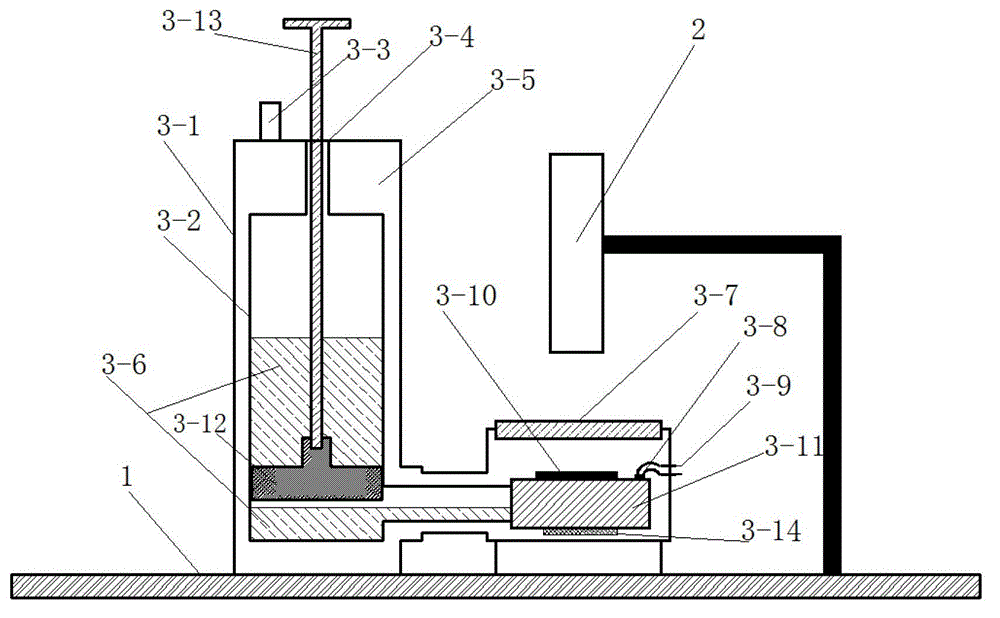

[0024] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

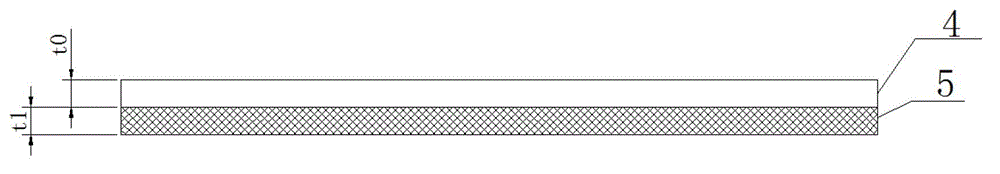

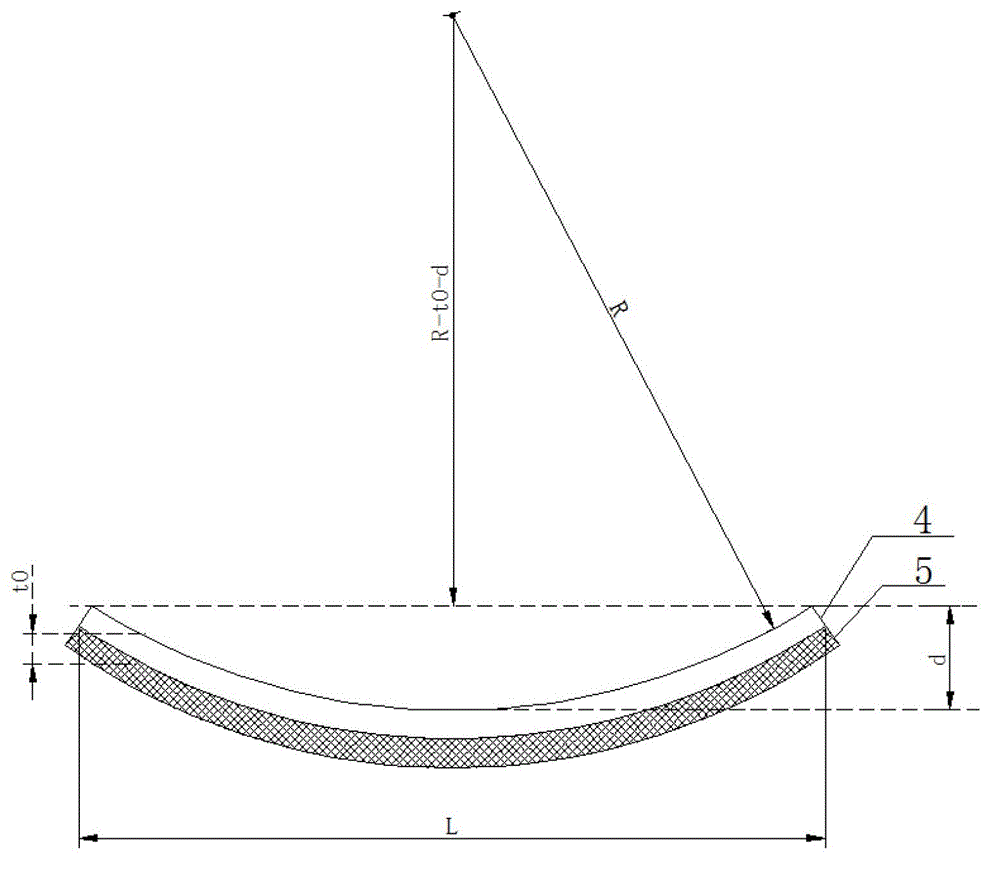

[0025] 1. In figure 2 In the double-layer structure shown, the coefficient of thermal expansion of the test piece 5 is smaller than that of the standard piece 4. When the temperature on the system drops, due to the relatively large thermal expansion coefficient of the standard piece, the degree of contraction is severe, and the system produces a deformation that is concave downward from the middle ,Such as image 3 Shown; the radius of curvature R in the figure, the maximum deformation deflection d at the center and the thickness t of the top standard sheet 0 Satisfies the relationship between:

[0026] 1 R = 6 ( 1 + m ) 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com