Simple measurement device for heat conductivity coefficient of porous ceramics

A technology of porous ceramics and thermal conductivity, applied in the field of thermal conductivity measurement, can solve the problems of limited size, high cost, high price, etc., and achieve the effects of low cost, convenient experimental operation, and few experimental operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

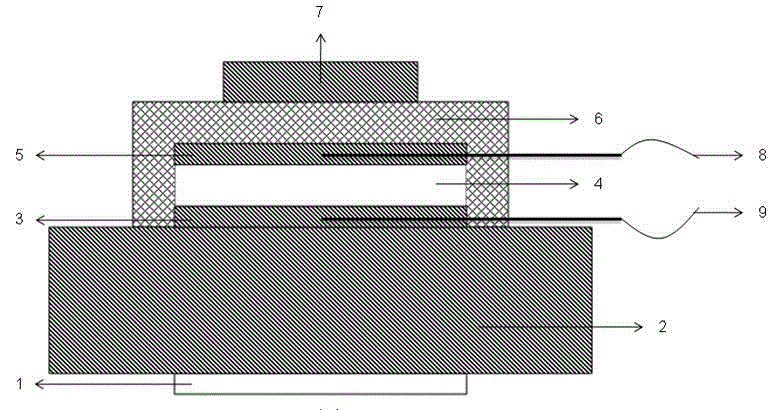

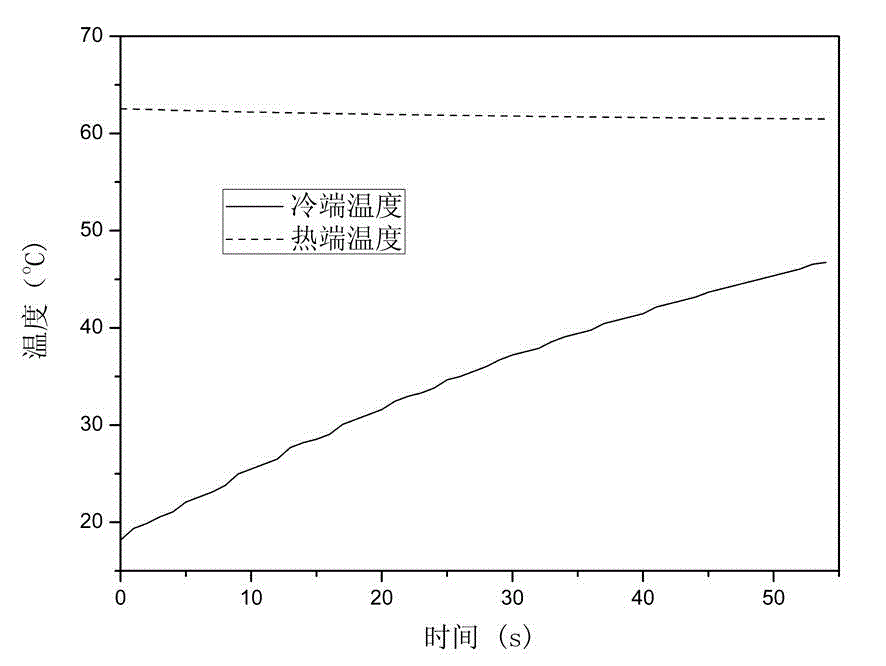

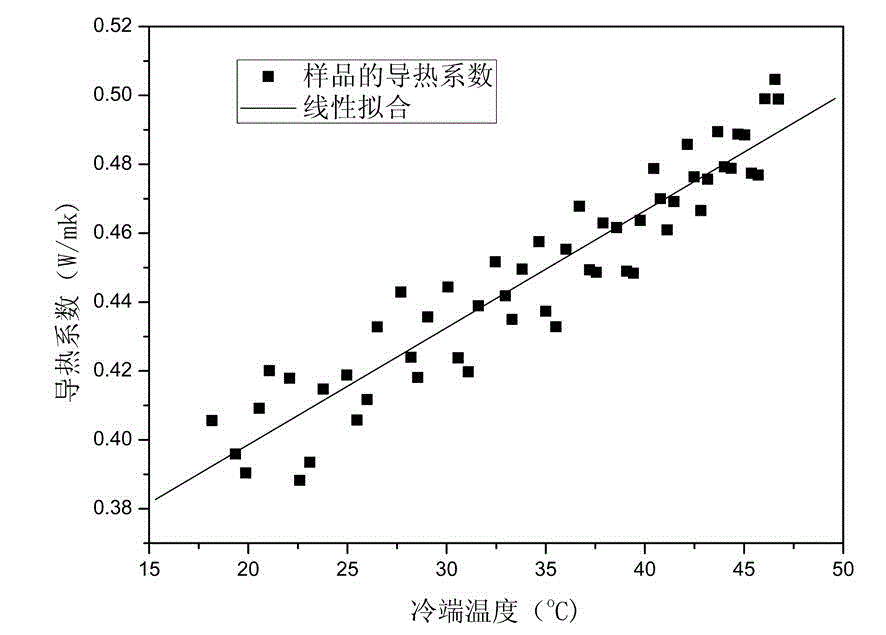

[0029] see figure 1 , the simple measurement device for the thermal conductivity of porous ceramics includes a heater 1 located at the bottom, and the heater is a high-temperature ceramic heating sheet. The top of the heater 1 is provided with a heat source 2, which is a circular thick iron block with a thickness of 30mm and a diameter of 60mm. The top of the heat source 2 is provided with upper and lower corresponding upper copper sheet 5 and lower copper sheet 3, the lower copper sheet 3 is in direct contact with the heat source 2 as the hot end, and the upper copper sheet 5 is the cold end; when measuring, the porous ceramic 4 to be measured is located on the upper Between the copper sheet 5 and the lower copper sheet 3; the measured porous ceramic 4 is a molded circular porous ceramic sheet with a diameter of 25mm and a thickness of 3mm; the diameter of the upper copper sheet 5 and the lower copper sheet 3 and the measured porous ceramic 4 The diameter is equivalent and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com