Conducting film, conducting film manufacturing method and touch screen with conducting film

A conductive film and touch screen technology, applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, circuit, etc., can solve the problem of poor conductivity of the conductive layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below in conjunction with accompanying drawing, the present invention will be further described.

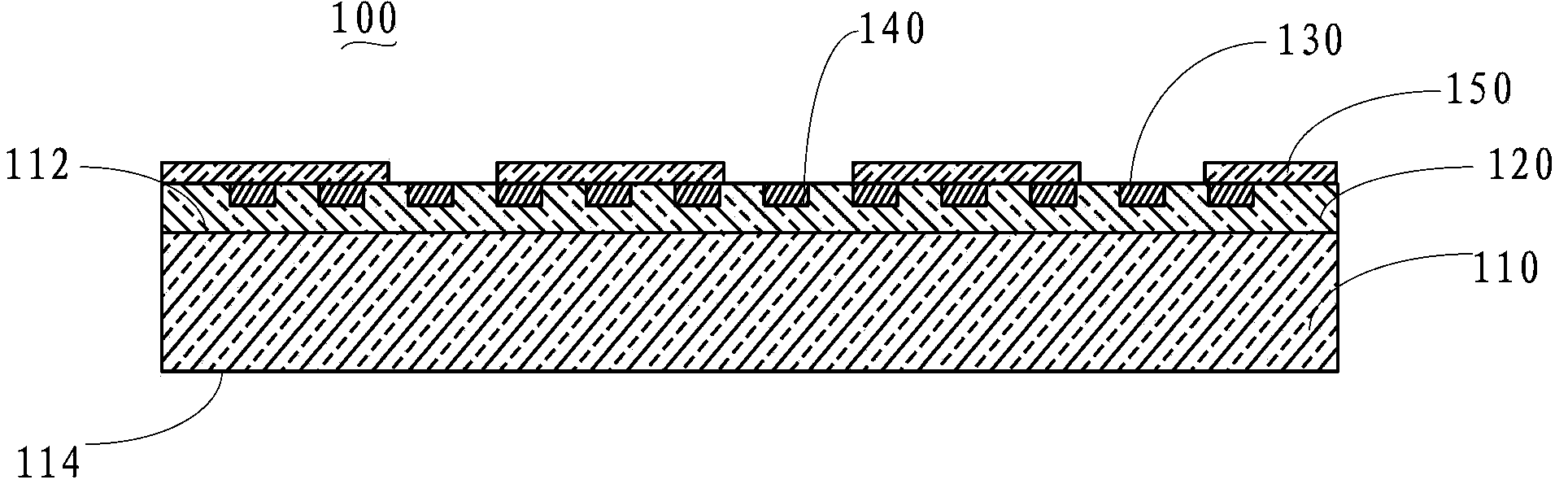

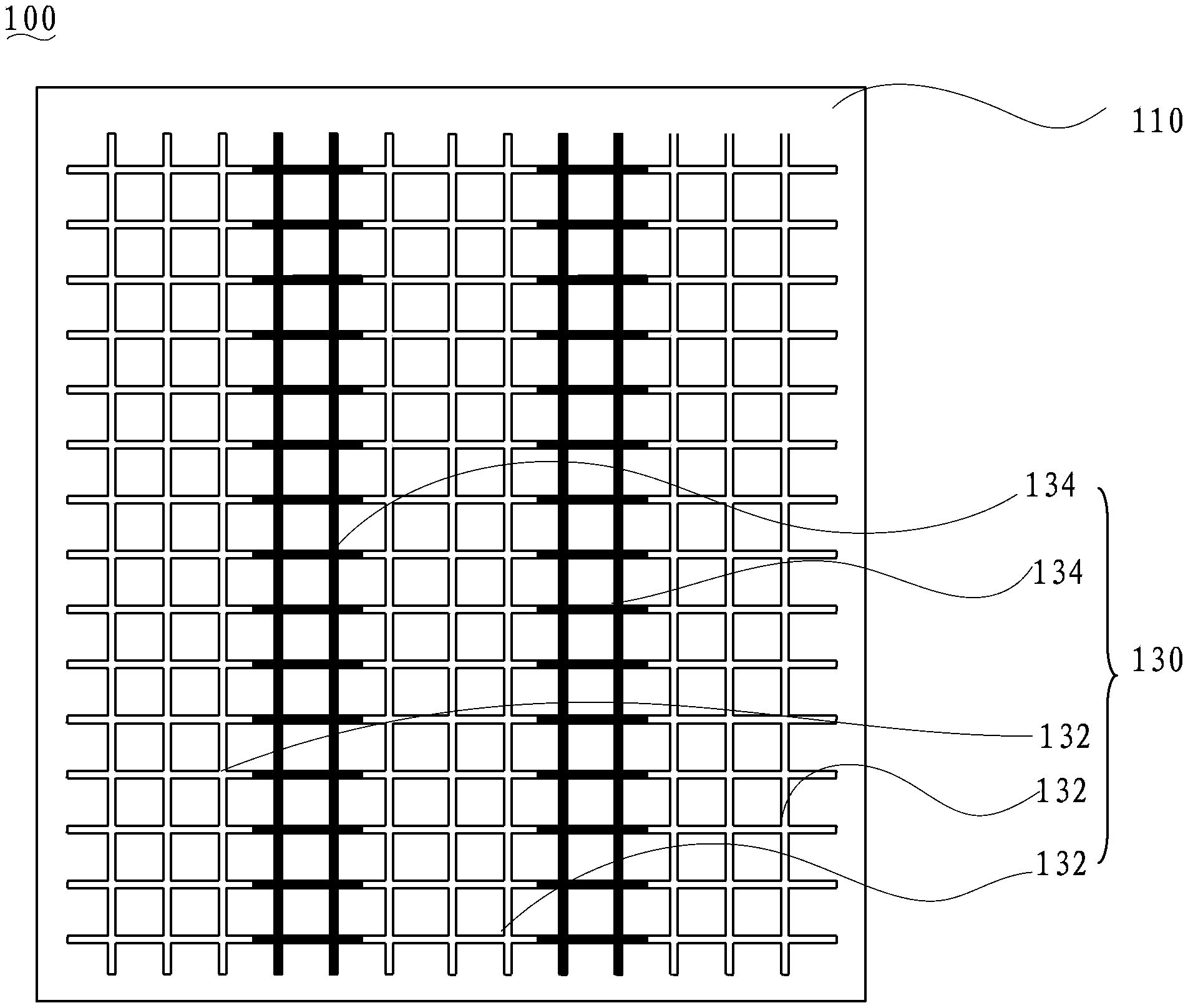

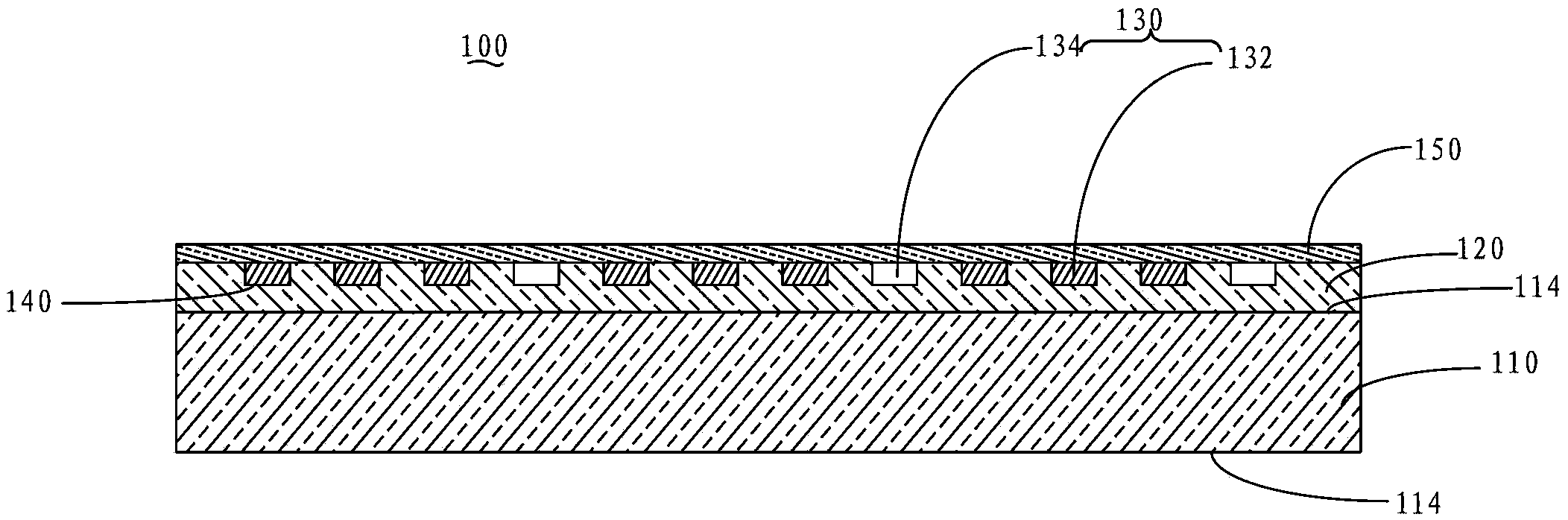

[0076] see figure 1 and figure 2 , In the first embodiment, a conductive film 100 includes: a substrate 110, a first matrix layer 120, a first conductive layer 130, a first groove 140 and a first anti-oxidation layer 150, and the substrate 110 includes a first A surface 112 and a second surface 114, the first surface 112 and the second surface 114 are oppositely arranged; the first matrix layer 120 covers the first surface 112 of the substrate 110; the first groove 140 is opened in The first matrix layer 120 is away from the side of the first surface 112; the first conductive layer 130 is accommodated in the first groove 140 to form an embedded grid, including a first conductive region 132 and a first insulating region 134 , the first conductive region 132 includes a metal grid line formed of metal, the first insulating region 134 is non-conductive, and the first insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com