Wind self-cleaning type composite insulator

A composite insulator, self-cleaning technology, used in insulators, electrical components, circuits, etc., can solve the problems of heavy insulators, hidden dangers of pollution flashover, etc., achieve high anti-aging, not easy to deform, and improve the effect of wind sweeping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

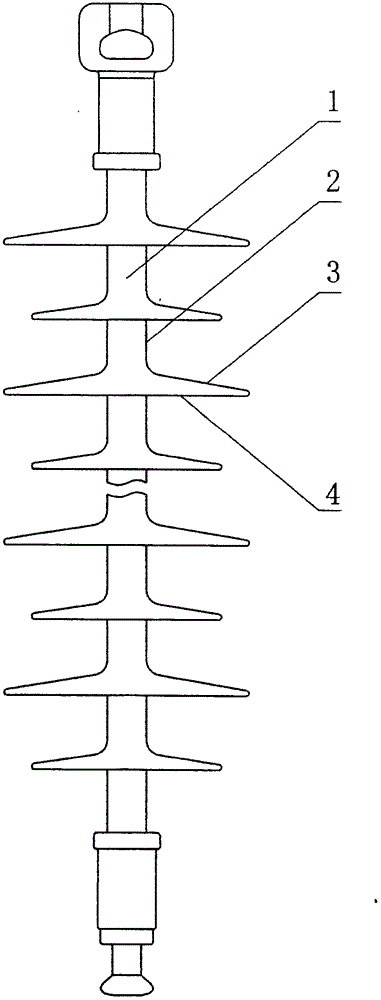

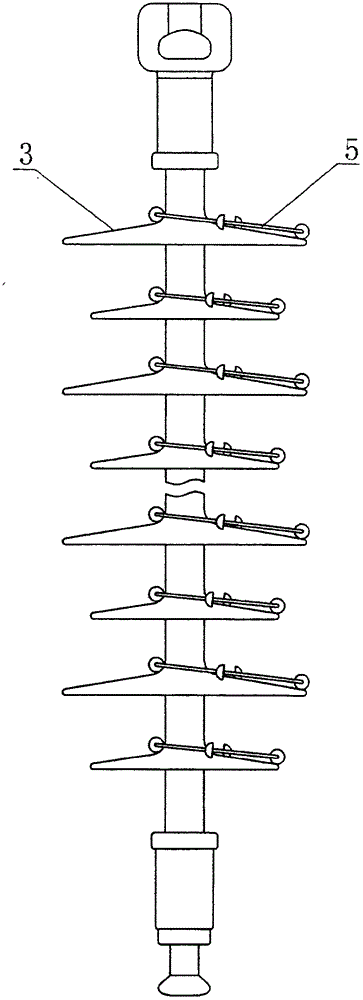

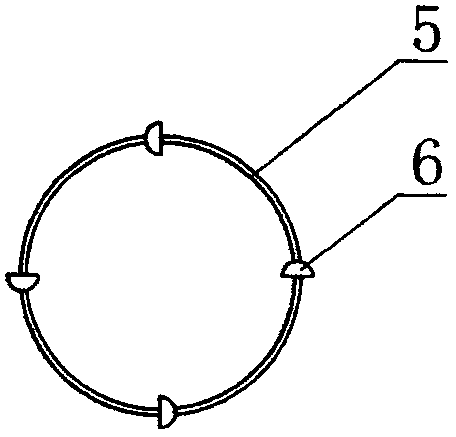

[0014] attached figure 1 It is a schematic diagram of the structure of the existing composite insulator. The existing composite insulator (1) is composed of a fitting ball head, a fitting ball socket, a rod core and a composite jacket. The upper surface (3) of the umbrella skirt is a conical surface, the lower surface (4) of the umbrella skirt is a plane, and the height (or length) of the composite insulator and the number of umbrella pieces are determined by the voltage level; figure 2 It is a structural schematic diagram of an existing composite insulator sleeve with a wind cleaning ring (5). image 3 It is the structural representation of Chinese patent (notification number CN1393891, CN300775682, CN301483468S) insulator wind cleaning ring (5), with Figure 4 is attached image 3 In the top view of the composite insulator with the cleaning ring (5), the anti-fouling flashover ability is greatly improved, but the wind cleaning ring (5) can only clean the upper surface (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com