Rubber composition for tire tread

A technology of rubber composition and tire tread, which is applied to special tires, tire parts, transportation and packaging, etc., and can solve problems such as inability to carry out, improvement in grip performance, lagging of rubber composition reinforcement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In this specification, unless otherwise specified, all percentages (%) shown are percentages by weight.

[0021] Furthermore, any numerical interval represented by the expression "between a and b" represents a numerical range from greater than a to less than b (i.e. excluding the limits a and b), while any numerical interval represented by the expression "a to b" A range of values from a to b (ie including the strict limits a and b) is intended.

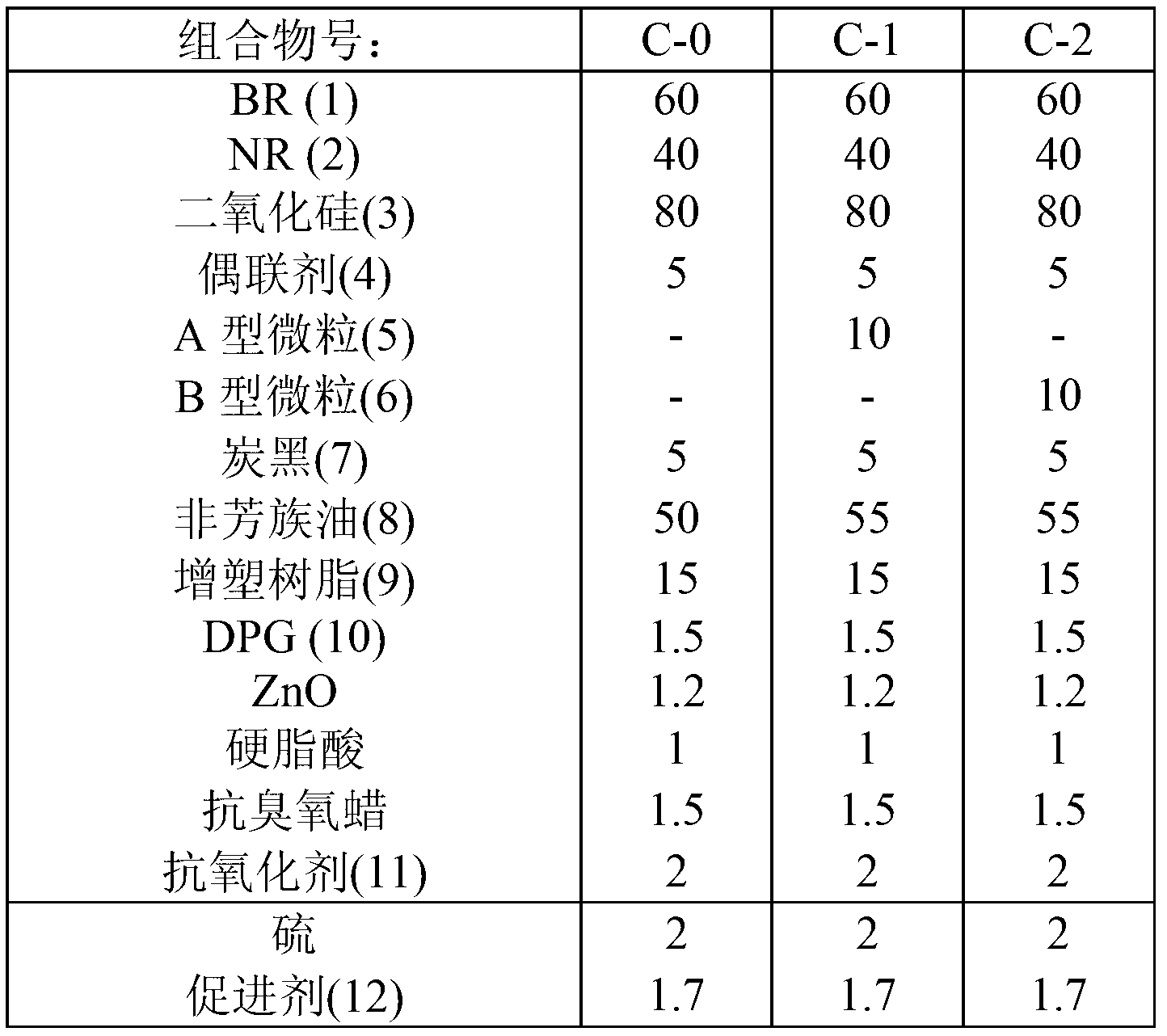

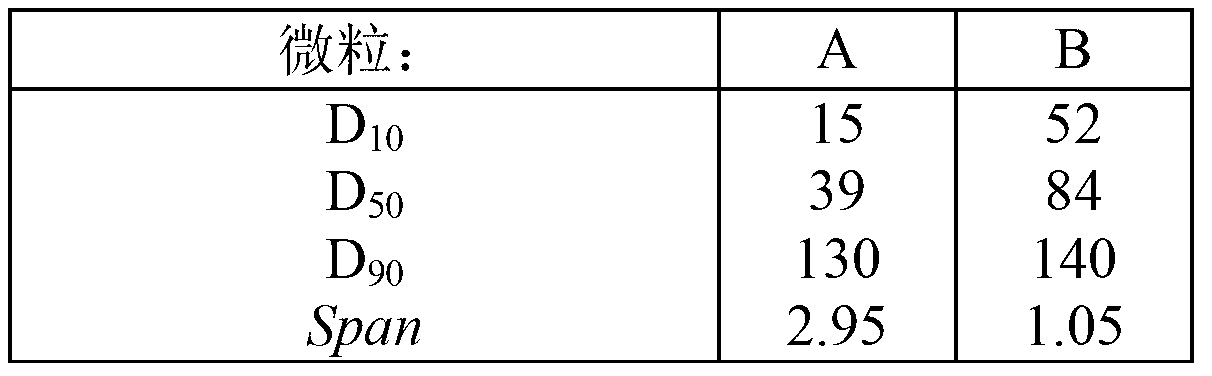

[0022] The rubber composition of the present invention is based on at least one diene elastomer, a liquid plasticizer, reinforcing fillers and fine particles of a water-soluble alkali metal or alkaline earth metal sulfate, these components being described in detail below.

[0023] The expression "based on" should of course be understood as meaning a composition comprising a mixture of the individual components used, or, if any, their reaction products, some of which are particularly capable of being used in the individual co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com